- Product Details

- {{item.text}}

Quick Details

-

MF:

-

C44H84N2O6

-

EINECS No.:

-

NIL

-

Place of Origin:

-

Shandong, China

-

Type:

-

plastic additives

-

Brand Name:

-

KINTER

-

Model Number:

-

KL-86

-

Product name:

-

Calicium Zinc stabilizer

-

Application:

-

PVC Solid Wall Plate, buckle gusset plate and other plates

-

Appearance:

-

White Power

-

Keywords:

-

PVC Heat Stabilizer

-

Color:

-

White Color

-

Package:

-

25kg/bag

-

Certification:

-

ISO9001

-

MOQ:

-

1 Kg

-

Sample:

-

Availabe

-

Grade:

-

Industrail Grade

Quick Details

-

CAS No.:

-

129757-67-1

-

Purity:

-

99.9%

-

Other Names:

-

calcium zinc stabilizer

-

MF:

-

C44H84N2O6

-

EINECS No.:

-

NIL

-

Place of Origin:

-

Shandong, China

-

Type:

-

plastic additives

-

Brand Name:

-

KINTER

-

Model Number:

-

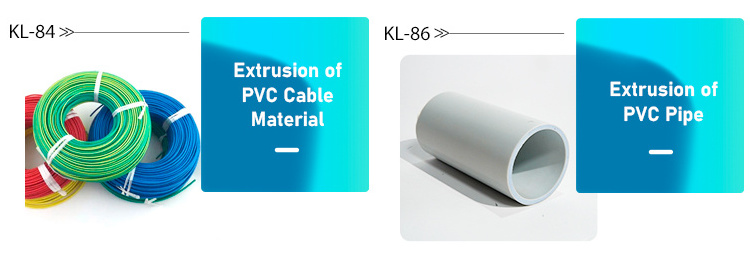

KL-86

-

Product name:

-

Calicium Zinc stabilizer

-

Application:

-

PVC Solid Wall Plate, buckle gusset plate and other plates

-

Appearance:

-

White Power

-

Keywords:

-

PVC Heat Stabilizer

-

Color:

-

White Color

-

Package:

-

25kg/bag

-

Certification:

-

ISO9001

-

MOQ:

-

1 Kg

-

Sample:

-

Availabe

-

Grade:

-

Industrail Grade

|

Product Name

|

KL-86 Series of Calcium-zinc Heat Stabilizers

|

|

|

Product Standard

|

Q/SDYH02-2022

|

|

|

Appearance

|

White or pale yellow,powder or flake

|

|

|

Storage & Transportation

|

Keep dry and ventilated, keep away from direct sunlight, keep separate from other chemicals.

|

|

|

Packaging

|

Paper-plastic composite bag or PP woven bag, 25kg/bag

|

|

|

Feature

|

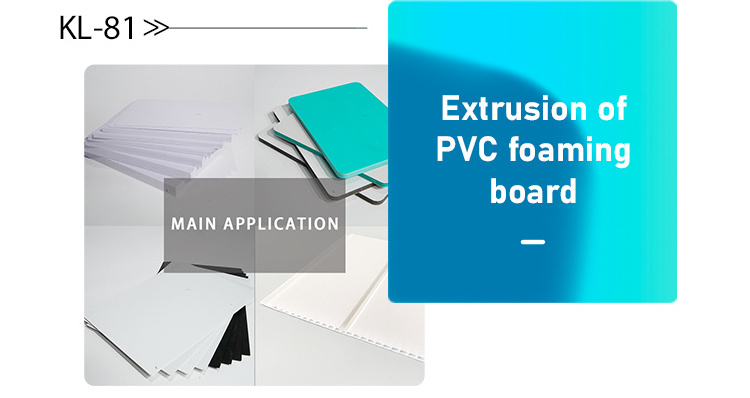

◆ Supply excellent lubrication and heat stabilization specifically designed for PVC foaming board.

◆ Non-toxic and environmental-friendly.

◆ Substitute for tin stabilizer and lead stabilizer, without sulfide pollution. ◆ Suitable for PVC foaming board with different thicknesses, densities and fillers. ◆ Contribute to the formation of homogeneous cellular foam structure inside foaming board. ◆ Great ability of fusion with PVC that improves the mechanical properties of products and reduces precipitation.

◆ Compliant with RoHS and REACH.

|

|

|

|

||

|

PVC Calcium-zinc Heat Stabilizers

|

PVC Ca-Zn Heat Stabilizer

|

|

|

|

|

|||||

|

Model

|

Model

|

Zn,%

|

Ca,%

|

Mass Loss on Heating,%

|

Recommended Use Level*1

|

|||||

|

KL-81

|

KL-8108

|

3.6-4.0

|

≤7.0%

|

≤4.0%

|

3.5-5.0 PHR

|

|||||

|

|

KL-8102X

|

2.8-3.2

|

≤2.0%

|

|

|

|||||

|

|

KL-8109D

|

3.6-4.0

|

≤12.0%

|

|

|

|||||

|

|

KL-203

|

3.0-4.0

|

≤5.0%

|

≤4.0%

|

3.8-4.8 PHR

|

|||||

|

|

KL-203A

|

2.5-4.0

|

|

|

|

|||||

|

|

KL-203Z

|

2.5-4.0

|

|

|

|

|||||

|

|

KL-8301

|

2.5-3.5

|

≤6%

|

≤4.0%

|

5.0-6.0 PHR

|

|||||

|

|

KL-8301G

|

|

|

|

4.5-6.0 PHR

|

|||||

|

|

KL-8405

|

2.5-4.0

|

≤15.0%

|

≤4.0%

|

5.0-8.0 PHR

|

|||||

|

|

KL-8405G

|

|

|

|

4.5-7.0 PHR

|

|||||

|

|

KL-850

|

2.5-3.5

|

≤7.0%

|

≤4.0%

|

3.5-5.0 PHR

|

|||||

|

|

KL-850C

|

|

≤9.0%

|

|

|

|||||

|

|

KL-8608

|

2.0-4.0

|

\

|

≤4.0%

|

2.5-4.0PHR

|

|||||

|

|

KL-8608D

|

|

|

|

|

|||||

|

|

KL-8608F

|

|

|

|

|

|||||

*1. PHR means parts per hundred units of PVC.

Application

Hot Searches