- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

Other

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

QT

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

950x1100x1100mm

-

Weight (KG):

-

800 kg

-

Product Name:

-

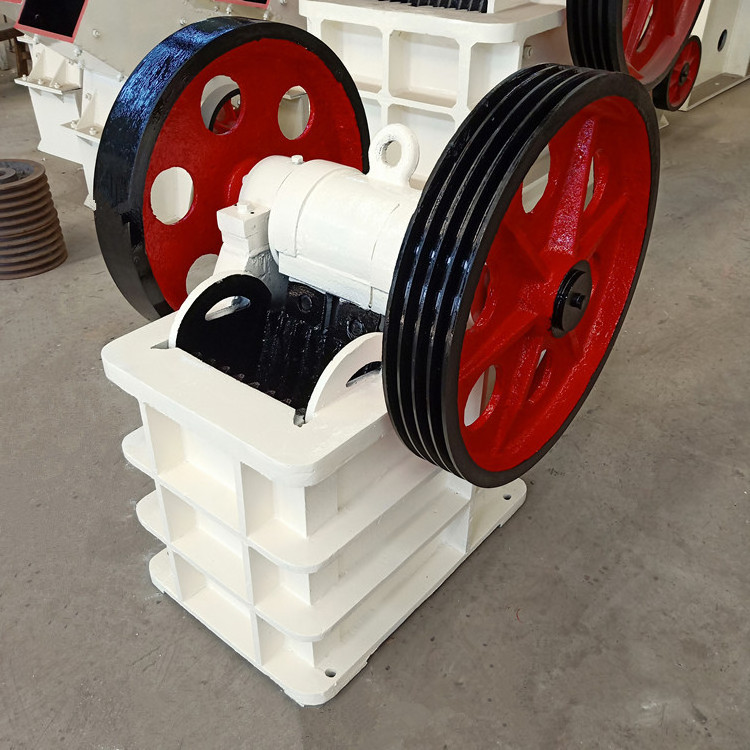

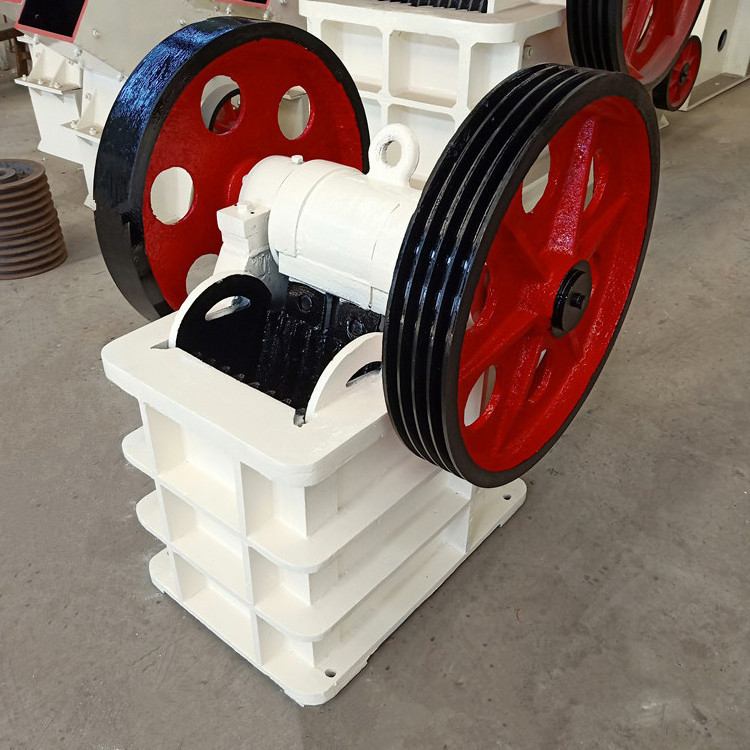

PE200X300 Jaw type stone breaker

-

Range of the material:

-

Hard raw material hammer crusher

-

Production capacity:

-

2000-5000 KG / h

-

particle size after treatment:

-

0-5mm

-

Wear resistant material:

-

Thicken the wear-resisting lining plate

-

Raw material moisture content:

-

Not more than 15%

-

Hammer head:

-

Casting of high manganese material

-

structure:

-

Hammer head is easy to replace

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine

-

Brick Raw Material:

-

Coal Gangue, Shale,stone

-

Production Capacity (Pieces/8 hours):

-

1200-3500 KG / h

-

Brick size:

-

Other

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

QT

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

950x1100x1100mm

-

Weight (KG):

-

800 kg

-

Product Name:

-

PE200X300 Jaw type stone breaker

-

Range of the material:

-

Hard raw material hammer crusher

-

Production capacity:

-

2000-5000 KG / h

-

particle size after treatment:

-

0-5mm

-

Wear resistant material:

-

Thicken the wear-resisting lining plate

-

Raw material moisture content:

-

Not more than 15%

-

Hammer head:

-

Casting of high manganese material

-

structure:

-

Hammer head is easy to replace

Product Description

Jaw crusher

P

erformance characteristics

Simple structure, stable performance, low operating cost, easy maintenance

Large crushing ratio and uniform discharging particle size Low noise, less dust, low operating cost, the crushing chamber is deep and has no dead zone, which improves the feeding capacity and output discharge port adjustment range is large, can meet the requirements of different users.

Equipment and energy saving

The cavity type of jaw stone breaker is the hyperboloid form of deep cavity. The structure of negative support, zero suspension, small eccentricity and high swing frequency matches with the deep cavity type, which makes it obtain the excellent performance of high processing capacity, low wear and low energy consumption. The energy saving of single machine is 15% ~ 30%, and the energy saving of the system is more than doubled.

Large crushing ratio and uniform discharging particle size Low noise, less dust, low operating cost, the crushing chamber is deep and has no dead zone, which improves the feeding capacity and output discharge port adjustment range is large, can meet the requirements of different users.

Equipment and energy saving

The cavity type of jaw stone breaker is the hyperboloid form of deep cavity. The structure of negative support, zero suspension, small eccentricity and high swing frequency matches with the deep cavity type, which makes it obtain the excellent performance of high processing capacity, low wear and low energy consumption. The energy saving of single machine is 15% ~ 30%, and the energy saving of the system is more than doubled.

Broken than big

The crushing ratio of jaw type stone breaker is very high. The so-called size takes all, and the effective dynamic design makes the material broken many times. The advanced crushing technology and the use of advanced digital processing equipment make the internal structure precise, improve the crushing performance, and the product size uniform.

Productivity is high

Reasonable crushing cavity design, good motion parameters, determine the best meshing Angle and stroke characteristic values, provide a larger crushing stroke, higher productivity and greater bearing capacity. The yield can be increased by 30-50%.

High service life

The use of advanced manufacturing technology, the use of advanced digital parts, the selection of high-end production materials, to ensure the precision of machine parts, greatly enhance its compression resistance, wear resistance, reduce maintenance costs at the same time, greatly extend the service life.

Manufacture advanced, compressive wear-resisting

The parts are made of high-end and high-quality materials, which enhance the compression resistance and wear resistance of the parts. The movable jaw is made of cast steel, and the eccentric shaft is processed by forging billet, so that the parts are more reliable and efficient and durable.

The jaw crusher

is composed of two jaw plates of moving jaw and static jaw, which simulate the movement of the two jaws of animals and complete the crushing operation of the crusher.Widely used in mine smelting, building materials, highway, railway, water conservancy and chemical industries and other crushing of a variety of ores and bulk materials.The high compressive strength of the crushed material is 320MPa.

Processing materials:

Pebble, granite, basalt, quartzite, iron ore, diabase, limestone, calcite, dolomite, barite, talc, gypsum, bentonite, etc

Application fields:

Sand and stone material field, power plant desulfurization, concrete mixing station, dry sand pulp, sand aggregate, quartz sand and so on.

The jaw crusher is mainly used as coarse crusher and medium crusher in mining, building materials, infrastructure and other departments.According to the width of the feed port, it is divided into three kinds: large, medium and small. The width of the feed port is larger than 600MM for the large machine, the width of the feed port is 300-600mm for the medium machine, and the width of the feed port is less than 300MM for the small machine.The jaw crusher has the advantages of simple structure, easy manufacture and reliable operation.

The jaw crusher's working part is two jaw plates, one is a fixed jaw plate (fixed jaw), vertical (or slightly outward inclined upper) fixed on the front wall of the body, the other is a movable jaw plate (moving jaw), the position is inclined, and the fixed jaw plate to form a large and small crushing cavity (working cavity).Periodically, the movable jaw plates reciprocate against the fixed jaw plates, sometimes apart, sometimes close.When separated, the material enters the crushing chamber, and the finished product is discharged from the lower part;When approaching, the material installed between the two jaw plates is crushed by extrusion, bending and splitting.

Processing materials:

Pebble, granite, basalt, quartzite, iron ore, diabase, limestone, calcite, dolomite, barite, talc, gypsum, bentonite, etc

Application fields:

Sand and stone material field, power plant desulfurization, concrete mixing station, dry sand pulp, sand aggregate, quartz sand and so on.

The jaw crusher is mainly used as coarse crusher and medium crusher in mining, building materials, infrastructure and other departments.According to the width of the feed port, it is divided into three kinds: large, medium and small. The width of the feed port is larger than 600MM for the large machine, the width of the feed port is 300-600mm for the medium machine, and the width of the feed port is less than 300MM for the small machine.The jaw crusher has the advantages of simple structure, easy manufacture and reliable operation.

The jaw crusher's working part is two jaw plates, one is a fixed jaw plate (fixed jaw), vertical (or slightly outward inclined upper) fixed on the front wall of the body, the other is a movable jaw plate (moving jaw), the position is inclined, and the fixed jaw plate to form a large and small crushing cavity (working cavity).Periodically, the movable jaw plates reciprocate against the fixed jaw plates, sometimes apart, sometimes close.When separated, the material enters the crushing chamber, and the finished product is discharged from the lower part;When approaching, the material installed between the two jaw plates is crushed by extrusion, bending and splitting.

Specification

|

Model

|

Size of feed port (mm)

|

Rotor Speed

(r/min)

|

Maximum feed size (mm)

|

Adjustment range of discharge port (mm)

|

Eccentric shaft speed (r/main)

|

Motor Power (KW)

|

|

PE-150×250

|

150×250

|

125

|

10-40

|

0.9-4.5

|

300

|

5.5

|

|

PE-250×400

|

250×400

|

210

|

20-60

|

4.5-19.5

|

300

|

15

|

|

PE-400×600

|

400×600

|

340

|

40-100

|

15-51

|

275

|

37

|

|

PE-500×750

|

500×750

|

425

|

50-100

|

30-78

|

275

|

55

|

|

PE-600×900

|

600×900

|

500

|

65-160

|

45-112.5

|

250

|

75

|

|

PE-750×1060

|

750×1060

|

630

|

80-140

|

108-195

|

250

|

90

|

|

PE-900×1200

|

900×1200

|

750

|

95-165

|

130.5-246

|

200

|

160

|

|

PE-1000×1200

|

1000×1200

|

850

|

195-265

|

295.5-321

|

200

|

160

|

|

PE-1200×1500

|

1200×1500

|

1020

|

150-300

|

375-750

|

180

|

200

|

|

PEX-150×750

|

150×750

|

120

|

18-48

|

7.5-24

|

320

|

15

|

|

PEX-250×750

|

250×750

|

210

|

25-60

|

12-33

|

330

|

30

|

|

PEX-250×1000

|

250×1000

|

210

|

25-60

|

15-48

|

330

|

37

|

|

PEX-250×1200

|

250×1200

|

210

|

25-60

|

19.5-57

|

330

|

45

|

|

PEX-300×1300

|

300×1300

|

250

|

20-90

|

15-97.5

|

300

|

75

|

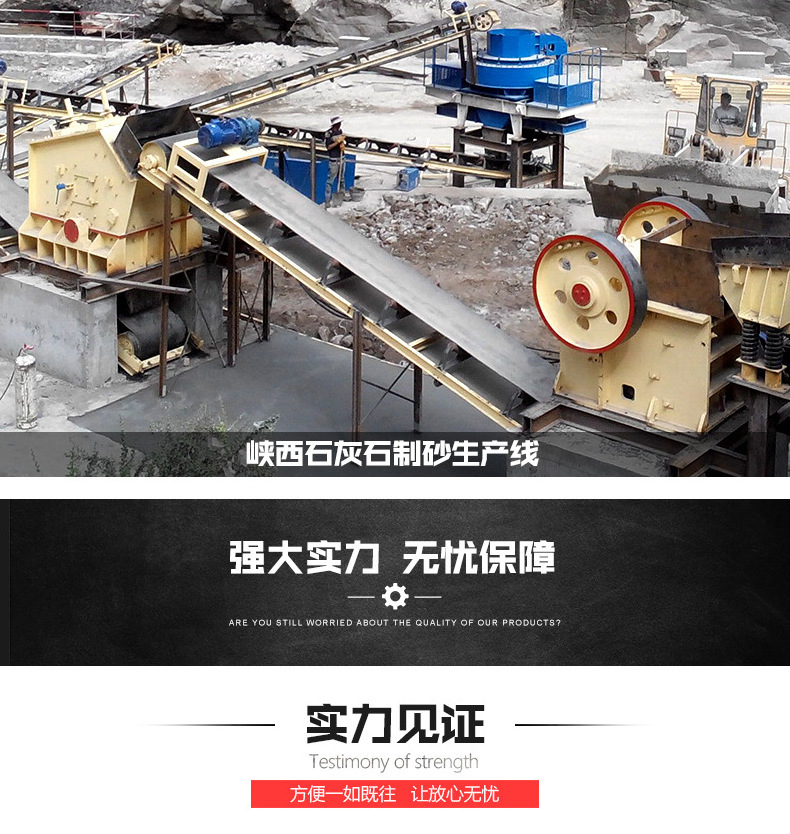

Packing & Delivery

We are a professional supplier of brick and tile production line solutions, including the preliminary site equipment process layout, the optimal combination of equipment matching, site construction scheme, equipment assembly and debugging, staff operation training and other complete plans, if you have any questions about the brick production line, welcome to consult, welcome to visit our company if you have the opportunity.

Hot Searches