Or

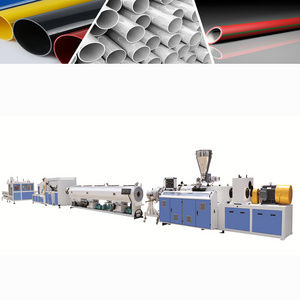

Model:

SJZ92/188

Capacity:

500-800kgs/h

Motor power:

110kW

Material of screw & Barrel:

38CrMoAl & Bimetallic