- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Zhendi, 19-YEAR Fiberglass Panels China Supplier

-

Model Number:

-

Fiberglass Panels for Trailer

-

Surface Treatment:

-

Gel Coat

-

Thickness:

-

1-4.0MM

-

Type:

-

Flat/Rolls

-

Color:

-

White, Blue, Yellow or Customized

-

Width:

-

100-3200MM

-

Length:

-

Customized Length

-

Surface:

-

Glossy or Matte

-

Feature:

-

Easy Clean, High Impact

-

Certificate:

-

ISO 9001:2005

-

Product name:

-

Glass Fiber Reinforced Polymer

Quick Details

-

Application:

-

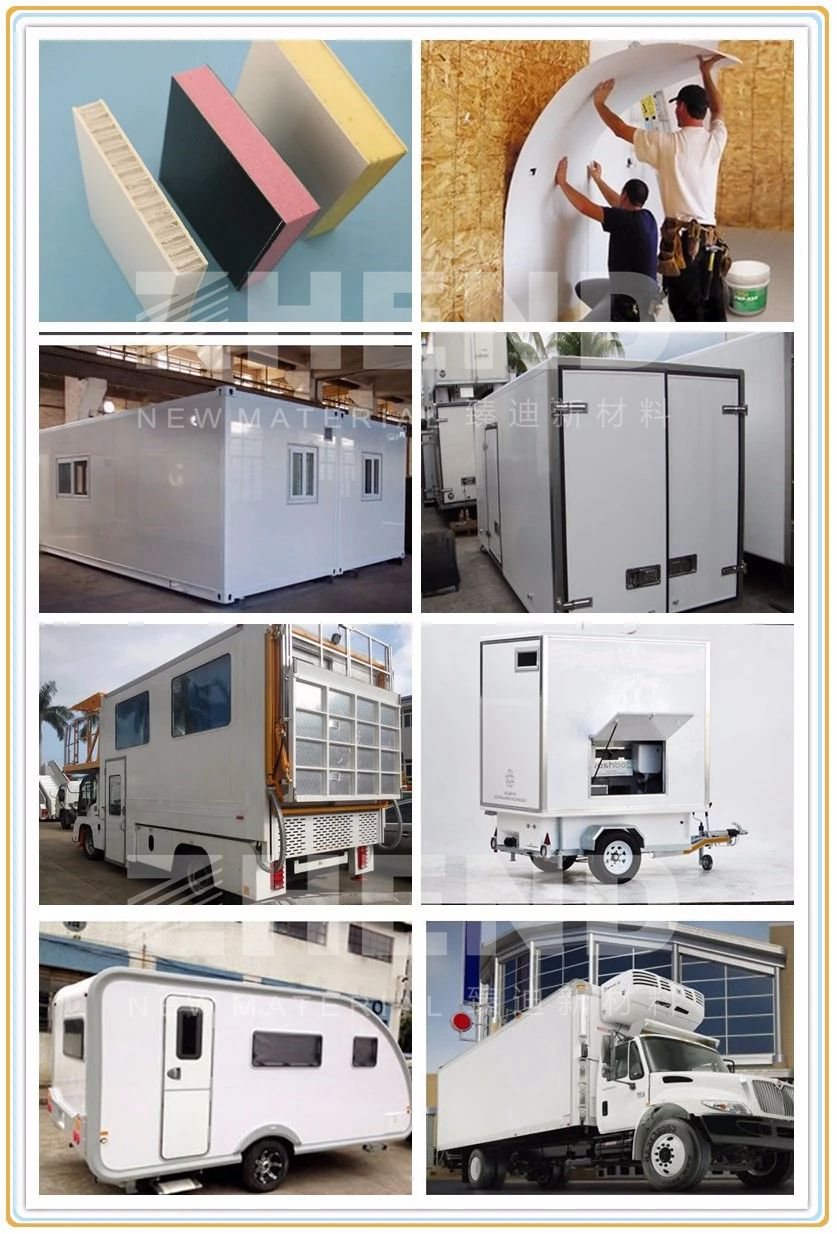

Trailers, Truck Box Body, Camper, RV, Caravan, RV Paneling

-

Technique:

-

Molded

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Zhendi, 19-YEAR Fiberglass Panels China Supplier

-

Model Number:

-

Fiberglass Panels for Trailer

-

Surface Treatment:

-

Gel Coat

-

Thickness:

-

1-4.0MM

-

Type:

-

Flat/Rolls

-

Color:

-

White, Blue, Yellow or Customized

-

Width:

-

100-3200MM

-

Length:

-

Customized Length

-

Surface:

-

Glossy or Matte

-

Feature:

-

Easy Clean, High Impact

-

Certificate:

-

ISO 9001:2005

-

Product name:

-

Glass Fiber Reinforced Polymer

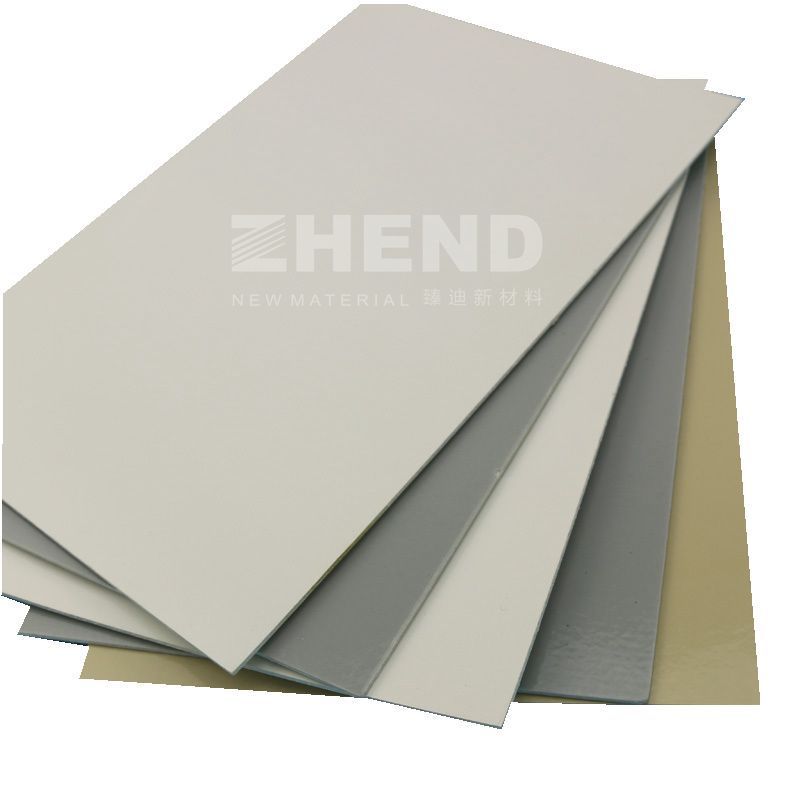

China Factory FRP GRP Glass Fiber Reinforced Plastics Sheet Panel Price for Truck Body

FRP glass fiber reinforced plastics panel for truck body (Fiberglass Panels RV) are a wonderful composite material consisting of fiberglass reinforcement in a matrix of unsaturated polyester resin and outer protective coating with u/v stabilized in built color of your choice having exceptional strength to weight ratio. Fiberglass reinforced plastic is generally known for its high strength and resistance to high temperatures, chemicals, bacteria or termite and excellent acoustic insulation. Because of these outstanding properties unlike PVC or Wood, it finds its application widely in all spheres of life – Aerospace, railways, chemical industry, marine industry, food industry, automobile industry, building and construction etc.

Main Features:

- Durability:FRP Sheets have very long life, as they are tough and flexible

- Light Weight&High Impact Strength: The relative density is between 1.5~2.0, only 1/4~1/5 of carbon steel, but the tensile strength is close to or even exceeds that of carbon steel.

- Highly corrosion-Resistant: FRP panels are also suitable for use in highly corrosive environments where exposure to chemicals or saltwater is a concern, are UV resistant to sun exposure and can be made with fire retardants when required.

- Excellent Thermal Insulation: The thermal conductivity of FRP is 1.25~1.67kJ/(m·h·K) under room temperature, only 1/100~1/1000 of metal. Therefore, It is an ideal thermal protection and ablation resistant material under transient ultra-high temperature conditions.

- Flexibility in Sizes and Thickness: FRP Sheets are custom made sheets and can be made in various sizes, thickness and designs.

- Easy to Install, Maintain and Clean.

- Customized Colour & Design: FRP Sheets can be made in any colour and in various des igns.

Options for Surface of Top Side of FRP/GRP Gel Coat sheet:

1. High Glossy/Shiny

2. Matte

Options for Surface of Back Side of FRP/GRP Gel Coat sheet:

1. Smooth

2. Rough

Finished Gel Coated Fiberglass Sheet at Our Workshop:

|

Coverage Material |

High Quality Anti-aging Polyester Gel Coating |

||||||||

|

Resin Material |

High Quality Polyester Resin |

||||||||

|

Reinforced Glass Fiber |

Taishan Fiberglass Chopped Strand Mat |

||||||||

|

Anti-ultraviolet Rate |

More Than 99% |

||||||||

|

Warranty |

10-15 years |

||||||||

|

Shape |

Flat/Coils/ Rolls |

||||||||

|

Length |

Customized(according to container) |

||||||||

|

Width |

Less than 3200MM |

||||||||

|

Thickness(mm) |

1.0 | 1.3 | 1.5 | 2 | 2.2 | 2.5 | 3 | 3.5 | 4 |

|

Weight(KG/SQM) |

1.4 | 1.82 | 2.1 | 2.8 | 3.08 | 3.5 | 4.2 | 4.9 | 5.6 |

|

Application |

Decoration of Interior Wall of Building, Caravan Wall, RV, Motor Homes and etc. |

||||||||

|

Fire proof rate |

Class A / Class B / Class C |

||||||||

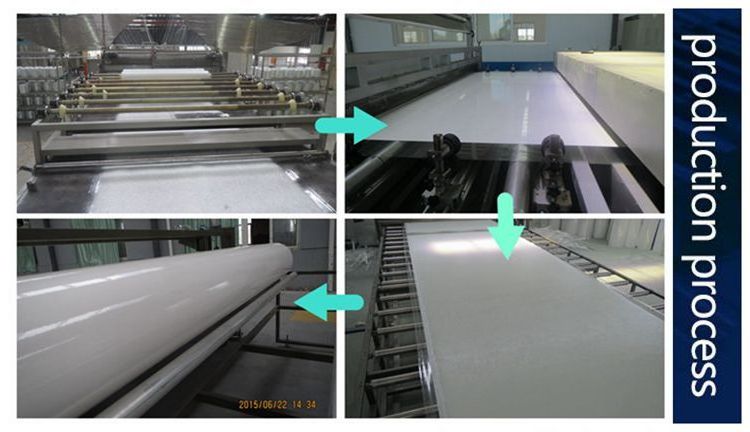

Production Process:

Main Advantages of Our Company:

1. 20 -YEAR FRP Sheet making machines manufacturer in China Has the latest production machines and production technology, thus ensure you get the best FRP products.

2. We have two production lines, one for the width less than 1500MM and the other for the width less than 3200MM. And the annual production capacity is more than 3,000,000SQ.M.

3. With ISO 9001:2005 Quality Management System Certificate approved, we have the strict quality control system from the raw material to the finished products.

Quality Control System:

|

Raw Material |

Choose Quality Supplier, Test it before Entering the Warehouse |

|

Mould |

Confirm the Size of Mould before production and Ensure the precision of the Design |

|

Experienced Workers |

Every Part has different workers to operate |

|

Production Machines |

Adjust the Temperature into the Appropriate Value and the Thickness and Speed |

|

Finished Product |

Test it before Entering the Warehouse and UN-qualified Product not Sold |

Quality Raw Materials:

Our Production Line:

Our Office and Workshop:

Our Exhibition:

Welcome to contact us for more RV Paneling Solutions!