- Product Details

- {{item.text}}

Quick Details

-

Year:

-

new

-

Power (kW):

-

60 kW

-

Weight (KG):

-

150 KG

-

Product name:

-

Rubber Vulcanizing Press

-

Application:

-

Rubbers Recycling Industry

-

Raw material:

-

Rubber Vulcanizing

-

Name:

-

Belt Vulcanizing Press

-

Function:

-

Heat Vulcanizer Press

-

Keyword:

-

Conveyor Belt Vulcanizer

-

End product:

-

Rubber Particle

-

Marketing Type:

-

Product 2023

-

Advantage:

-

High Producing Efficiency

Quick Details

-

Place of Origin:

-

Chongqing, China

-

Voltage:

-

Customer's Request

-

Dimension(L*W*H):

-

customizable

-

Year:

-

new

-

Power (kW):

-

60 kW

-

Weight (KG):

-

150 KG

-

Product name:

-

Rubber Vulcanizing Press

-

Application:

-

Rubbers Recycling Industry

-

Raw material:

-

Rubber Vulcanizing

-

Name:

-

Belt Vulcanizing Press

-

Function:

-

Heat Vulcanizer Press

-

Keyword:

-

Conveyor Belt Vulcanizer

-

End product:

-

Rubber Particle

-

Marketing Type:

-

Product 2023

-

Advantage:

-

High Producing Efficiency

Products Description

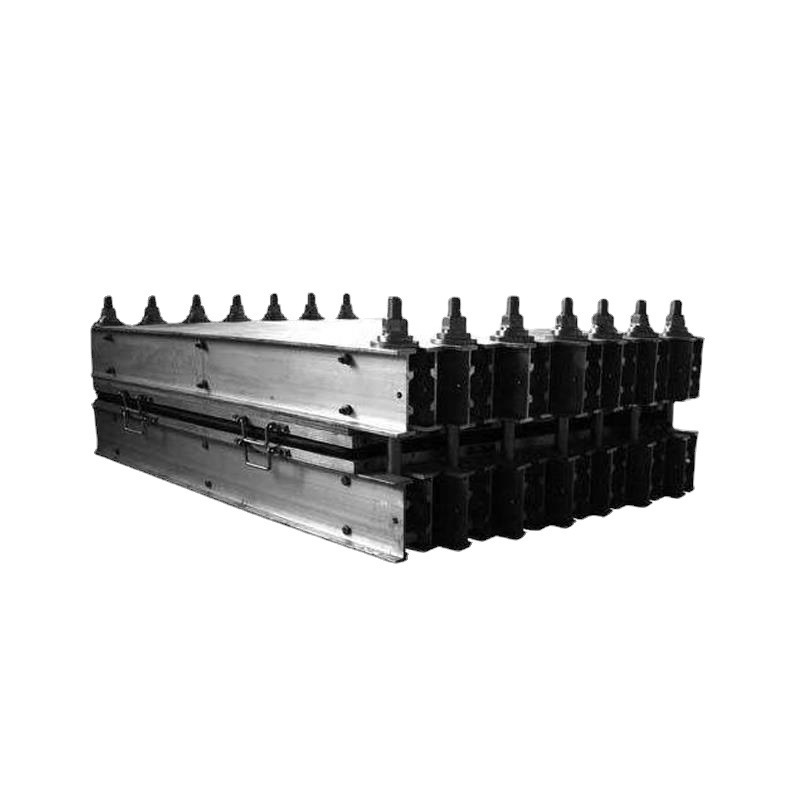

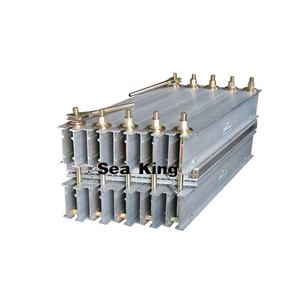

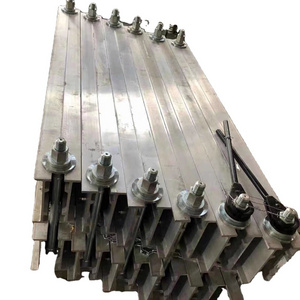

Belt Vulcanizing Machine

, also known as

Electrothermal Belt Vulcanizing Machine

, is a special equipment for conveyor belt. The machine is made of lightweight aluminum alloy material, which has the features of small volume, light weight of single piece, easy disassembling and assembling, and suitable for manpower moving. At the same time, it has the characteristics of fast heating, uniform temperature and high thermal efficiency,

which is an ideal equipment for rubber belt joints of conveyor machinery.

The product is widely used and can be applied to the transportation joints of the conveyor in the field of gold treatment, chemical industry, metal mines, power plants, ports and wharves. The tensile strength of the vulcanized rubber lining is not less than 90% of the original belt, the joint is smooth, and it can reduce the wear and tear on the roller and prolong the service life of the conveyor and rubber belt.

|

Product name

|

LBD explosion-proof electric heating type repair vulcanizing machine

|

|

Adhesive tape width(mm)

|

800、1000、1200、1400、1600、1800

|

|

Vulcanization repair temperature

|

145℃

|

|

Vulcanization repair pressure

|

1—2Mpa

|

|

Heating plate warming time

|

<30min

|

|

Rated Working Voltage

|

380/660/1140V

|

|

Power

|

2KW—22KW

|

|

OEM

|

Color&Logo

|

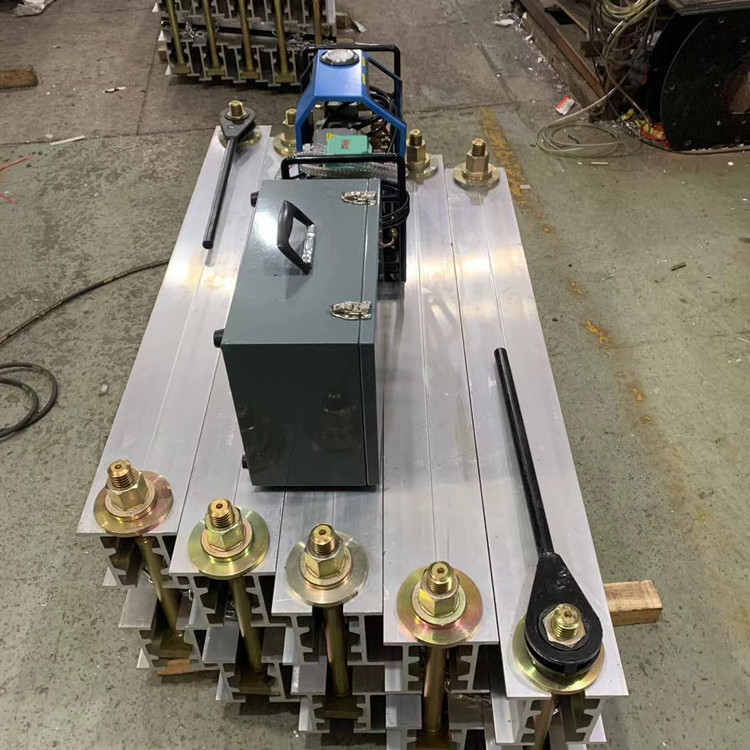

LBD explosion-proof electric-heat type repair vulcanizing machine is suitable for gluing canvas, nylon steel rope core tape joints in underground coal mines and places with explosive hazardous mixtures of methane or coal dust, with light weight, easy operation, work, reliable, and is the advanced explosion-proof vulcanizing machine in China.

LBD explosion-proof electric heating type repair vulcanizer is made of lightweight aluminum alloy material, with small volume, light weight of single piece, easy to disassemble, suitable for manpower to move. At the same time, it has the characteristics of fast heating, uniform temperature, high thermal efficiency, etc. It is an ideal equipment for rubber belt joints of conveying machinery.

|

LBD explosion-proof electric heating type repair vulcanizing machine performance characteristics

|

|

1.LBD explosion-proof electric heating type repair vulcanizing machine adopts PC or manual control, with reliable performance and high degree of automation. It can automatically recognize wrong commands and avoid accidents caused by wrong operation.

|

|

2. The pre-programmed process can be locked, the operator can not change without authorization to ensure the quality of pressed products.

|

|

3. It has the functions of timed mold opening, automatic deflating and automatic pressure replenishment.

|

|

4. Manual, automatic and electric operation modes are available for selection.

|

|

5. The electrically heated press adopts digital display (pointer type) temperature control to control and display the temperature of the heating plate.

|

25T/50T/100T Plate Vulcanizing Machine

Hot press molding machine

(also known as

plate vulcanizing machine, rubber vulcanizing machine, foam plate vulcanizing machine,

) is a kind of molding machine, suitable for rubber, plastic industry of polymers, such as PVC and other chemical raw materials mixing and processing, dosage test to detect whether to achieve the required color and quality, can be used as a factory batch production before the dosage of the basis.

25T/50T/100T Plate Vulcanizing Machine

Plastic or rubber raw materials will be placed in the mold, sandwiched between the upper and lower electric heating plate, in the electric heating plate intelligent thermostat pressure, so that the raw material molding.

Packaging & Transportation

more product

Hot Searches