- Product Details

- {{item.text}}

Quick Details

-

Shelf life:

-

12 Months

-

Material:

-

100% silicone

-

Application:

-

Sealing Construction

-

Appearance:

-

Smooth and uniform paste;no bubble;no crust;No particles

-

Color:

-

Clear, white and black customized

-

Keywords:

-

silicone sealant

Quick Details

-

CAS No.:

-

7085-85-0

-

Place of Origin:

-

Shandong, China

-

Product name:

-

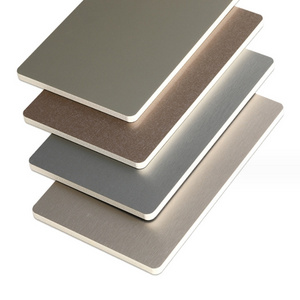

best price 995 aluminium composite panel silicone emulsion sealant

-

Shelf life:

-

12 Months

-

Material:

-

100% silicone

-

Application:

-

Sealing Construction

-

Appearance:

-

Smooth and uniform paste;no bubble;no crust;No particles

-

Color:

-

Clear, white and black customized

-

Keywords:

-

silicone sealant

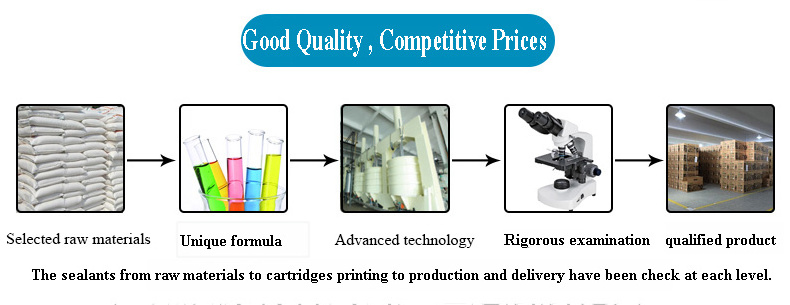

Outdoor use best price 995 aluminium composite panel silicone emulsion sealant

FEATURE

-One component, neutral cured, multipurpose use sealant.

-Good resistance to air aging. No corrosion to building materials.

-Especially for the common assembly and weatherproofing sealing.

-Excellent adhesion to most non-porous building materials without primer.

APPLICATIONS

Mainly applied in waterproofing sealing for all kinds of win-doors, glasses and other non-porous building materials.

COLORS

Neutral silicone sealant is available: Clear, White, black ,gray. We can also supply the other color according to the customer’s requirement.

PACKAGING

Cartridge package: 280ml, 300ml , 24 cartridges/ carton.

Sausage package: 590ml, 20 sausages/carton.

STORAGE AND USABLE LIFE

Neutral silicone sealant should be stored in a dry, cool and well ventilated place, where the temperature is below 27. From the date of production, the storage period is 12 months.

ADVANTAGE

1. Factory Direct Price

2. 20 Years of Production Experience

3. Minimum OEM

4. Free Sample

5. First Order Discount

|

|

Item |

Technical Data |

|

|

1 |

Appearance |

Paste |

|

|

2 |

Density g/cm3 |

1.38±0.05 |

|

|

3 |

Tack free time/ min |

20-40 |

|

|

4 |

Flow, Sag or Slump |

Vertical Deposited, mm |

≤1 |

|

Level Deposited |

No Distortion |

||

|

5 |

Extrusion / ml/min |

≥200 |

|

|

6 |

Elastic Recovery % |

≥88 |

|

|

7 |

Hardness/Shore A |

35~42 |

|

|

8 |

Ultimate Tensile Strength /Mpa |

>0.4 or >0.6 |

≥0.42 |

|

9 |

Tensile properties at maintained extension |

No Destroy |

|

|

10 |

Cold extension-heat compression |

No Destroy |

|

|

11 |

Cohesion property after immersion in water |

No Destroy |

|

|

12 |

Tensile properties at maintained extension after ultraviolet |

No Destroy |

|

|

As cured after 28 days at 23±2℃, RH50±5% |

|||