- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Wongs

-

Voltage:

-

220V/380V

-

Power:

-

7.5KW

-

Dimension(L*W*H):

-

210*80*160cm

-

Weight:

-

500 kg

-

Warranty:

-

1 Year

-

Marketing Type:

-

New Product 2023

-

After-sales Service Provided:

-

Online or sent engineer to your factory

-

Product Name:

-

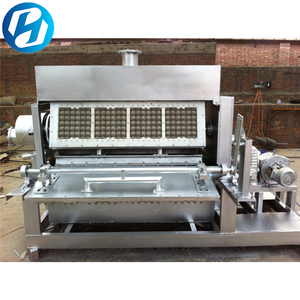

Paper pulp molding machine

-

Material:

-

SS 304

-

Type:

-

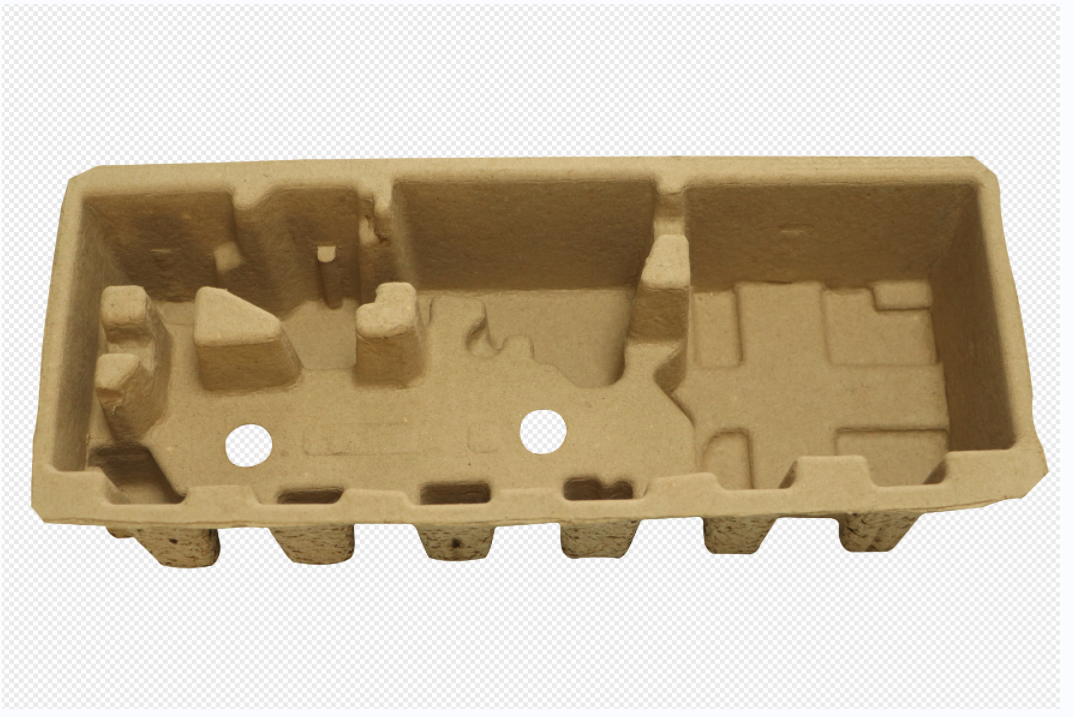

Make industrial packages

-

Usage:

-

Shaping egg carton

-

Color:

-

Customized Color

-

Pressure:

-

20 T

-

Table size:

-

600*800mm

-

Structure:

-

four-guide pillar

-

Machine Size:

-

1.38*1.06*2.4m

Quick Details

-

Production Capacity:

-

80 pcs/min

-

Processing Type:

-

shaping machine

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Wongs

-

Voltage:

-

220V/380V

-

Power:

-

7.5KW

-

Dimension(L*W*H):

-

210*80*160cm

-

Weight:

-

500 kg

-

Warranty:

-

1 Year

-

Marketing Type:

-

New Product 2023

-

After-sales Service Provided:

-

Online or sent engineer to your factory

-

Product Name:

-

Paper pulp molding machine

-

Material:

-

SS 304

-

Type:

-

Make industrial packages

-

Usage:

-

Shaping egg carton

-

Color:

-

Customized Color

-

Pressure:

-

20 T

-

Table size:

-

600*800mm

-

Structure:

-

four-guide pillar

-

Machine Size:

-

1.38*1.06*2.4m

Product Overview

Industrial Packages Making Machine

1.Pulp Moulding production line is known as egg tray line for using massively in produce

egg tray.

2.Pulp Moulding production line, which uses waste paper, cardboard, leftover material of paper mill, by hydraulic pulper, mix making a certain dense pulp, and pulp is absorbed by vacuum of special metal moulding to become wet products, through drying , and shaping to become finished products.

3.Pulp Moulding Line processing makes use of recycled water and does not lead to water or air pollution. Finished packaging products can be recycled after being used in storage, transport, and sales. After shredding, they are easy to be decomposed as paper, even if discarded into the natural environment.

4.Automatic pulp molding production lines can be mass production of various food container, egg tray, lunch boxes and so on.

egg tray.

2.Pulp Moulding production line, which uses waste paper, cardboard, leftover material of paper mill, by hydraulic pulper, mix making a certain dense pulp, and pulp is absorbed by vacuum of special metal moulding to become wet products, through drying , and shaping to become finished products.

3.Pulp Moulding Line processing makes use of recycled water and does not lead to water or air pollution. Finished packaging products can be recycled after being used in storage, transport, and sales. After shredding, they are easy to be decomposed as paper, even if discarded into the natural environment.

4.Automatic pulp molding production lines can be mass production of various food container, egg tray, lunch boxes and so on.

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

|

1

|

Power

|

30KW

|

|

|

2

|

Speed

|

300-500pcs/hr

|

|

|

3

|

Operating

|

PLC

|

|

|

4

|

Table size

|

600*800mm

|

the size can custom made

|

|

5

|

Table Number

|

1 or 2

|

|

|

6

|

Dryer

|

under sun or meta ldryer

|

|

Products Description

Our Advantages

1. The cover and The slurry tank on moulding machine is made of stainless steel.

2. The slide of transfer mode is anti-friction material.

3. The copper plate in the pumping area is filled up with wear resistant material.

4. Sealed with bearings on whole forming machine.

2. The slide of transfer mode is anti-friction material.

3. The copper plate in the pumping area is filled up with wear resistant material.

4. Sealed with bearings on whole forming machine.

Why Choose Us

Excellent characters

1.high speed;

2.saving power;

3.good quality;

4.stable working;

5.competitive price;

6.high production capacity;

7.automaticlly;

8.exquisite technology;

9.can design according to your request.

Perfect service:

1. Technical consultation;

2. Project evaluation;

3. Detailed design of factory;

4. Installing and testing the whole production line;

5. Training engineers and workers;

6. Supplying spare parts for long time.

Competitive company:

OEM----Our company----Hebei Wongs Machinery Equipment Co.,Ltd,located in Shijiazhuang city,China,is a leading professional paper

machine manufacturer and supplier in China with best quality and perfect service.

Technology strength:

1.one professional technician team of 116 engineers and 12 experts;

2.31 years rich practice experience;

3.one innovate research team,always follow the advanced technology of Finland,Denmark and Italy

4.skilled and careful workers;

Our market:

Our machines sells well in more than 30 countries and regions,such as

Russia,Indonesia,Uzbekistan,Tajikstan,Nigeria,Uganda,Pakistan,Egypt,Bhutan,Fiji,Brazil,Paraguay,Syria,Libya,Turkey,Canada etc,high

quality and perfect service have reserved customer's praise and more orders,we also establish good strategic cooperation with

local distributor.

1.high speed;

2.saving power;

3.good quality;

4.stable working;

5.competitive price;

6.high production capacity;

7.automaticlly;

8.exquisite technology;

9.can design according to your request.

Perfect service:

1. Technical consultation;

2. Project evaluation;

3. Detailed design of factory;

4. Installing and testing the whole production line;

5. Training engineers and workers;

6. Supplying spare parts for long time.

Competitive company:

OEM----Our company----Hebei Wongs Machinery Equipment Co.,Ltd,located in Shijiazhuang city,China,is a leading professional paper

machine manufacturer and supplier in China with best quality and perfect service.

Technology strength:

1.one professional technician team of 116 engineers and 12 experts;

2.31 years rich practice experience;

3.one innovate research team,always follow the advanced technology of Finland,Denmark and Italy

4.skilled and careful workers;

Our market:

Our machines sells well in more than 30 countries and regions,such as

Russia,Indonesia,Uzbekistan,Tajikstan,Nigeria,Uganda,Pakistan,Egypt,Bhutan,Fiji,Brazil,Paraguay,Syria,Libya,Turkey,Canada etc,high

quality and perfect service have reserved customer's praise and more orders,we also establish good strategic cooperation with

local distributor.

Hot Searches