- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINBO

-

Voltage:

-

380V or as required

-

Dimension(L*W*H):

-

5800*1200*1200mm

-

Weight:

-

2500 kg

-

Marketing Type:

-

Hot Product 2022

-

Material:

-

thin galvanized sheets

-

Material length:

-

Max 3600MM

-

Power:

-

6kw

-

Power supply:

-

380V, 50Hz, 3 phrases or at buyer's requirement

-

Diameter Of corrugation rolls:

-

380mm*2 pieces

-

Diameter Of pinch rolls:

-

340mm*2 pieces

-

Productivity:

-

30--36 sheets from 0.14--0.20mm

-

Exit table:

-

It is set to receiving and supporting the corrugation sheets.

-

Barrel Length:

-

3600 MM

-

After Warranty Service:

-

Video technical support, Online support

Quick Details

-

Type:

-

Tile Making Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINBO

-

Voltage:

-

380V or as required

-

Dimension(L*W*H):

-

5800*1200*1200mm

-

Weight:

-

2500 kg

-

Marketing Type:

-

Hot Product 2022

-

Material:

-

thin galvanized sheets

-

Material length:

-

Max 3600MM

-

Power:

-

6kw

-

Power supply:

-

380V, 50Hz, 3 phrases or at buyer's requirement

-

Diameter Of corrugation rolls:

-

380mm*2 pieces

-

Diameter Of pinch rolls:

-

340mm*2 pieces

-

Productivity:

-

30--36 sheets from 0.14--0.20mm

-

Exit table:

-

It is set to receiving and supporting the corrugation sheets.

-

Barrel Length:

-

3600 MM

-

After Warranty Service:

-

Video technical support, Online support

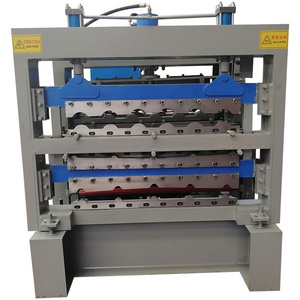

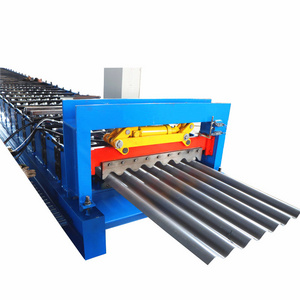

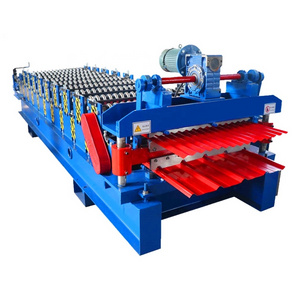

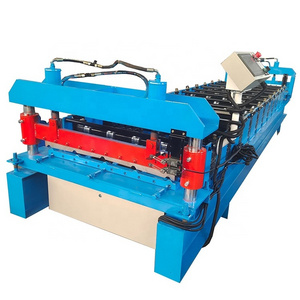

Zinc Iron Corrugated Sheet Roll Forming Machines Roof Panel making machine

Corrugated roof panel roll forming machine is a machine that is used to create corrugated metal roofing panels. These panels are commonly used in industrial and residential roofing applications due to their durability and strength. The machine works by feeding metal coils through a series of rollers that shape the material into a corrugated pattern.

Processing Flow:

Uncoiling → Feeding material into machine →Roll forming → Hydraulic cutting →Products receiving table

Uncoiling → Feeding material into machine →Roll forming → Hydraulic cutting →Products receiving table

|

Item

|

Specification

|

|

Processing Material

|

PPGI,GI,Aluminium

|

|

Material of Rollers

|

45# steel,with heat treatment

|

|

Diameter of Shaft

|

Ф70mm

|

|

Roller Driven

|

Decelerating Motor+Chain Transmission

|

|

Cutting Model

|

Hydraulic Profile Cutting

|

|

Length Measurement

|

Encoder

|

|

control method

|

PLC control system(imported Brand)

|

|

Total Power

|

15+11kw

|

|

Voltage

|

380V 50HZ or at buyer's request

|

Certification

Hot Searches