- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sinton

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

2.5 KG

-

Working Temperature Range:

-

25 - 220 ℃

-

Core Components:

-

resistance wire

-

Product name:

-

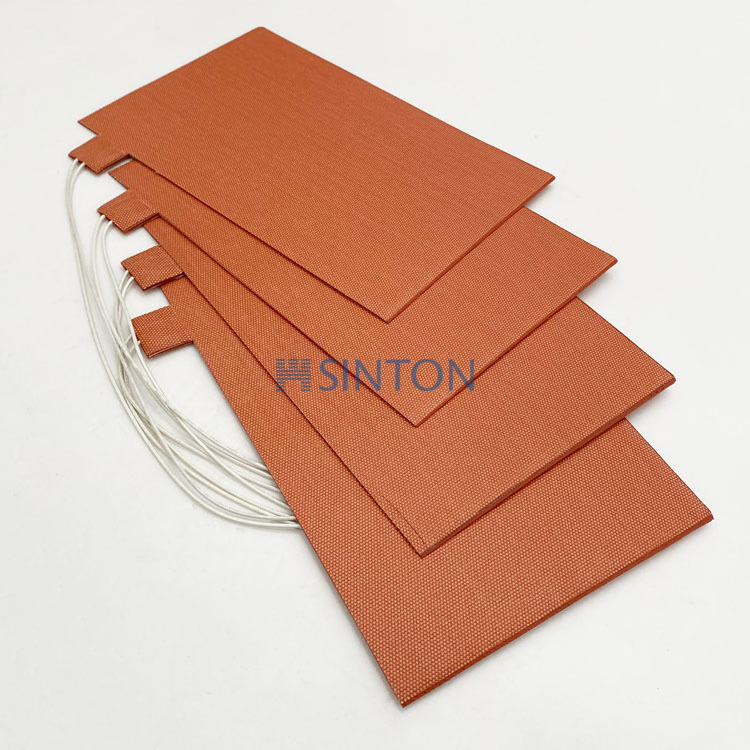

Silicone Heating Blankets for a Snowboard Press

-

After-sales Service Provided:

-

Overseas service center available

-

Dimension(L*W*H)::

-

Customized

-

Normally thickness::

-

1.5mm

-

Standard lead line::

-

200mm

-

Material::

-

Silicone rubber

-

Shape::

-

rectangular , square, round

-

After Warranty Service:

-

Online support

-

Application:

-

Cryoprotection, medical equipment

Quick Details

-

Type:

-

Band Heater

-

Power Source:

-

Electric

-

Voltage:

-

120V or 240V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sinton

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

2.5 KG

-

Working Temperature Range:

-

25 - 220 ℃

-

Core Components:

-

resistance wire

-

Product name:

-

Silicone Heating Blankets for a Snowboard Press

-

After-sales Service Provided:

-

Overseas service center available

-

Dimension(L*W*H)::

-

Customized

-

Normally thickness::

-

1.5mm

-

Standard lead line::

-

200mm

-

Material::

-

Silicone rubber

-

Shape::

-

rectangular , square, round

-

After Warranty Service:

-

Online support

-

Application:

-

Cryoprotection, medical equipment

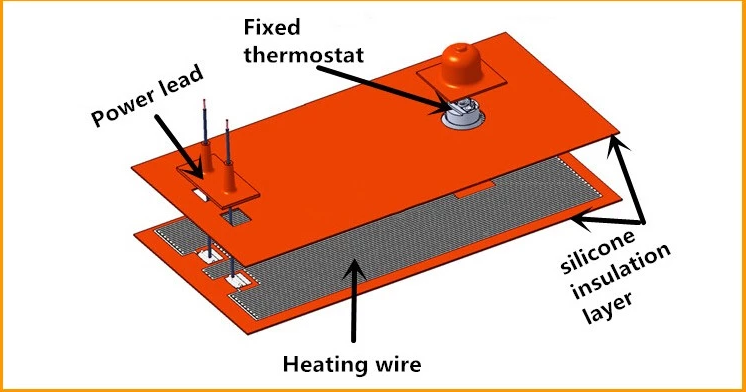

Introduction:

Silicone rubber heating pad is a kind of thin film which heaters upon electrified, in a standard thickness of 1.5mm, Adopting nickel chrome wires or 0.05 mm~0.10mm thick nickel chrome foils etched to some certain shapes, the heating component is wrapped with heat conducting and insulating materials on both sides, and completed in high temperature die forming and aging heat treatment. Due to its high reliability, the product is highly competitive when comparing with other electric heating film products which normally have paste materials such as graphite paste or resistor paste, etc. coated on insulation materials. As a kind of soft red film which can be applied closely on different curved surfaces, the silastic heater can be fabricated in varies shapes and powers.

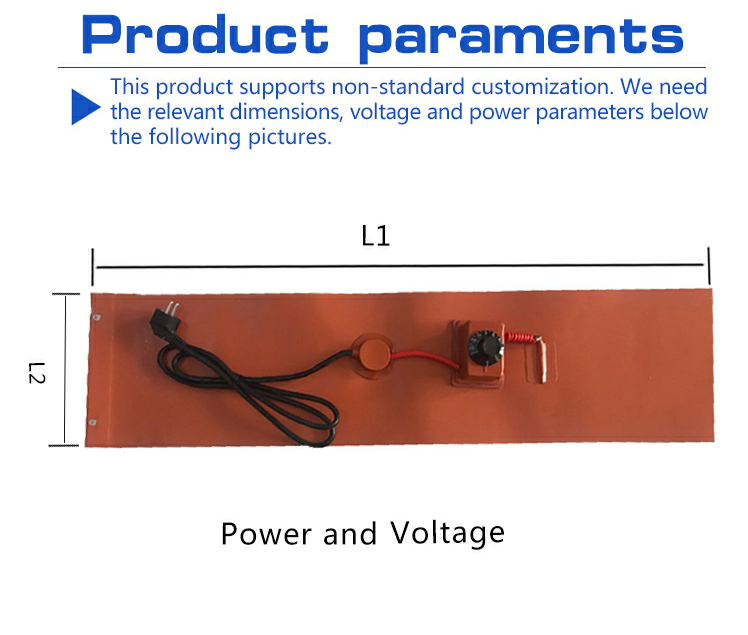

The specifications:

2.The use temperature: 200 ° C

3. Insulation resistance: ≥5MΩ

4.Pressure strength: ≥ AC1500V/5S

5.Power deviation: ± 8%

6.Voltage range: 1.5-380V

7.Unit power: 1.5W / CM2.

Note: the length can be customized according to customer requirements, the width is not more than 1.2 meters, if more than 1.2 meters can be spliced, size, voltage, power, and installation method can be customized according to customer needs.

|

Size(mm)

|

Power(w)

|

Voltage(v)

|

|

1000*15

|

90w

|

220v

|

|

2000*15

|

180w

|

220v

|

|

3000*15

|

270w

|

220v

|

|

1000*20

|

120w

|

220v

|

|

2000*20

|

240w

|

220v

|

|

3000*20

|

360w

|

220v

|

|

1000*25

|

150w

|

220v

|

|

2000*25

|

350w

|

220v

|

|

3000*25

|

450w

|

220v

|

1. Maximum temperature resistantof insulation : 200 ℃

2. Best continuous working temperature as 150 degree, max temperature as 230 degree momentarily.

3. Power deviation : 8% insulation resistance : >= 5MΩ

4. Compressive strength : 1500V/5s

5. Standard dimension : width: 20mm-1000mm ; Length : 25mm-1000mm; lead wire length : 200mm.

6. Fast heat diffusion , uniform heat transfer , directly heat objects on ; high thermal efficiency , high strength , long service life ,work safe , uneasy for ageing.

1. Silicone rubber band heater can be used in damp , no explosive gas atmosphere, industrial equipment pipelines, heat preservation for can and barrel .

2. It can be used as a frozen prevention, air conditioner compressor ,assisting heating of elctrical equipment .

3. Also it can be used as medical equipmentand medical care (such as blood tube heater, blood analyzer, heat supplementary for corset and waistband).

Q:

What is our competitive advantage?

A:You are ordering directly from the factory.We provide one-stop service, from order taking, customized research and development, to product follow-up, after-sales, etc. If

you buy our products, we are responsible for you to play the end.

Q: What is the lead time for Heater products?

A: Samples - within 3 working days with materials in stock Mass production - usually 7-14 working days (depends on quantity and raw material situation, please further discuss with our team. )

Q: What is the MOQ for Heater products?

A: Reheat products produced with common materials can be ordered at 1pcs. If infrequently used materials required, it depends on the situation of the materials.

Q: Do you manufacture custom parts?

A: Yes. We have thousands of designs in our files of custom heaters and sensors designed for every imaginable application. Our Sales and Engineering teams are here to help you design a product that fits your needs.

Q: If we have heating projects, how to progress project design or select a product?

A: We have professional sales to provide pre-sale consulting services and engineering team for technical support. Any

questions about products or technical questions please communicate with our sales team and provide specific applications and requirements.