Advantages:

simple design, reliable operation, easy maintenance, high degree of crushing and productivity.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

57000 KG

-

Crusher type:

-

Primary Crushing Machine

-

Feed particle size:

-

≤500 mm

-

Power:

-

100-2000 kw

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Quality:

-

Advanced Technology

-

Machines classification:

-

Mining Crusher Machine

-

Test&Installation:

-

Engineers On-site Guidance

-

Spare parts supply:

-

Anytime

-

Features:

-

High Efficiency Low Cost

-

Price:

-

Negotiatable

Quick Details

-

Application:

-

Minig industry

-

Place of Origin:

-

HEN

-

Brand Name:

-

Aimix

-

Weight:

-

57000 KG

-

Crusher type:

-

Primary Crushing Machine

-

Feed particle size:

-

≤500 mm

-

Power:

-

100-2000 kw

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Quality:

-

Advanced Technology

-

Machines classification:

-

Mining Crusher Machine

-

Test&Installation:

-

Engineers On-site Guidance

-

Spare parts supply:

-

Anytime

-

Features:

-

High Efficiency Low Cost

-

Price:

-

Negotiatable

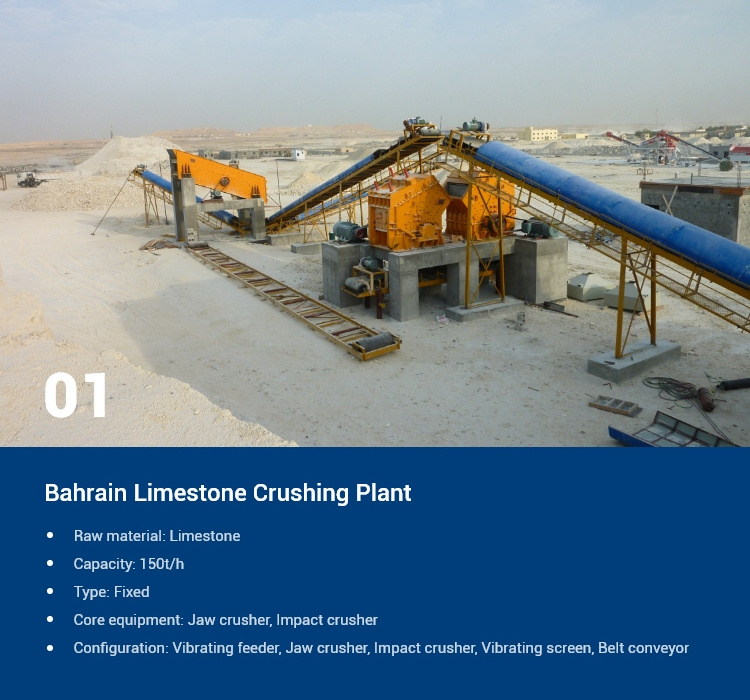

Success Cases

Crushing & Screening Solutions

Aimix focuses on the research and production of various stone and construction waste crushing equipment. Customize the configuration and construction plan of the crushing line for customers based on the characteristics of different raw materials.

DSK Design Solutions

The reasonable hardware configuration can enhance productivity and reduce operating costs. Aimix will develop a customized solution for each client based on the required size of stone materials.

|

Equipment configuration list

|

|

|

|

Capacity (T/H)

|

200

|

|

|

Feeder

|

1

|

|

|

Jaw crusher

|

1

|

|

|

Impact crusher

|

1

|

|

|

Vibrating screen

|

1

|

|

The Crushing & Screening Process

Different Crushers For Kinds of Stone

Typically the jaw crusher is used for primary crushing of ores and hard rocks with high hardness.

Raw materials: river pebbles, basalt, granite, iron ore, copper ore, cement, limestone.

Vertical shaft impact crusher is the most efficient and reliable equipment in the field of artificial sand and stone shaping.

Impact crusher is applied to crush medium-hard and brittle materials.

Advantages: high degree of crushing, good shape of crushed products, high productivity, ability to process materials of various shapes and sizes.

Our Services

Custom Design

Aimix provide design and customize service for various types of crushing plants according to the requirements of the client.

Installation Guide

Provide installation guidance, including online resources or on-site training, to ensure the normal operation of the crushing plant.

Technical Support

Aimix provide technical support include usage guidance, troubleshooting, technical consultation, and other services to ensure crushing plants long-term stable operation.

Spare Parts

Provide customers with various spare parts and components for crushing plants to ensure timely replacement of necessary parts.

FAQ

Q1: How about the crusher line maintenance ?

A1: Please check and maintained the whole line a

fter using. Clean the equipment and inspect it for damage, and repair it if it is damaged.

If there any technical questions, please feel free to consult online engineers.

Q2: Do you provide free spare parts for the crusher line ?

A2: We provide free spare parts in warranty 12 months.

Q3: How about your payment term ?

A3:

30% deposit in T/T advance, 70% balance before shipment. Also we provide the credit method.

Q4: Do you provide o

n-site installation and trial operation service?

A4: Sure friend. Aimix engineers team provide on-site service. We also have overseas offices in Philippines, Malaysia, Indonesia, Uzbekistan, etc to provide service within 24 hs.

Hot Searches