- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

3

-

Range of Spindle Speed(r.p.m):

-

2500 - 3800 r.p.m

-

Place of Origin:

-

China

-

Brand Name:

-

CD

-

Voltage:

-

220/380(Can customize)

-

Dimension(L*W*H):

-

756*650*1000mm

-

Weight (KG):

-

130 KG

-

Product name:

-

Universal hammer milling machine

-

Usage:

-

Food/herb/leafty etc

-

Material:

-

Stainless Steel 304

-

Capacity:

-

30-90kg/h

-

Color:

-

Silvery

-

Feed size:

-

10-20mm

-

Grinding size:

-

20-120M

-

Spindle speed:

-

3800r/min

-

Motor power:

-

3KW

-

Dimensions:

-

756*650*1000mm

Quick Details

-

Output (kg/h):

-

30 - 90 kg/h

-

Feeding Size (mm):

-

10 - 20 mm

-

Output Size (mesh):

-

20 - 120 mesh

-

Power (kW):

-

3

-

Range of Spindle Speed(r.p.m):

-

2500 - 3800 r.p.m

-

Place of Origin:

-

China

-

Brand Name:

-

CD

-

Voltage:

-

220/380(Can customize)

-

Dimension(L*W*H):

-

756*650*1000mm

-

Weight (KG):

-

130 KG

-

Product name:

-

Universal hammer milling machine

-

Usage:

-

Food/herb/leafty etc

-

Material:

-

Stainless Steel 304

-

Capacity:

-

30-90kg/h

-

Color:

-

Silvery

-

Feed size:

-

10-20mm

-

Grinding size:

-

20-120M

-

Spindle speed:

-

3800r/min

-

Motor power:

-

3KW

-

Dimensions:

-

756*650*1000mm

Product Description

Note:

1- Grinding rule: raw products is more smaller & brittle,moisture more lower,screen size

more larger, the capacity is more larger

2- Equip 3Pcs screens for getting different size powder products,

please inform if need customize size

|

Machine name

|

Universal hammer milling machine

|

|

Model

|

CD-HM-180

|

|

Power

|

3KW

|

|

Capacity

|

30-90kg/h

|

|

Grinding size

|

20-120M(Can customize)

|

|

Dimensions

|

756*650*1000mm

|

|

Weight

|

130Kg

|

|

Note

|

Machine usually equip

3Pcs screens

|

Working principle

The water-cooled hammer milling machine uses the high-speed movement of the hammer to make the crushed material inside the crushing cavity, and the hammer is impacted, knocked, cut and rubbed at high speed, and the collision and friction between the materials, so as to obtain crushing.

The material falls through the screen into the aggregate bucket or cloth bag below the crushing cavity. Bags are generally used to keep the dust inside the bag, and air and a small amount of extremely fine dust are discharged out of the bag through the gap in the bag.

The material falls through the screen into the aggregate bucket or cloth bag below the crushing cavity. Bags are generally used to keep the dust inside the bag, and air and a small amount of extremely fine dust are discharged out of the bag through the gap in the bag.

Application

Trial picture show of grinding Eaglewood & Fried garlic slices

Can do the

coarse crushing &

fine crushing

10M,20M,50M,80M,100M,120M ETC

Detailed Images

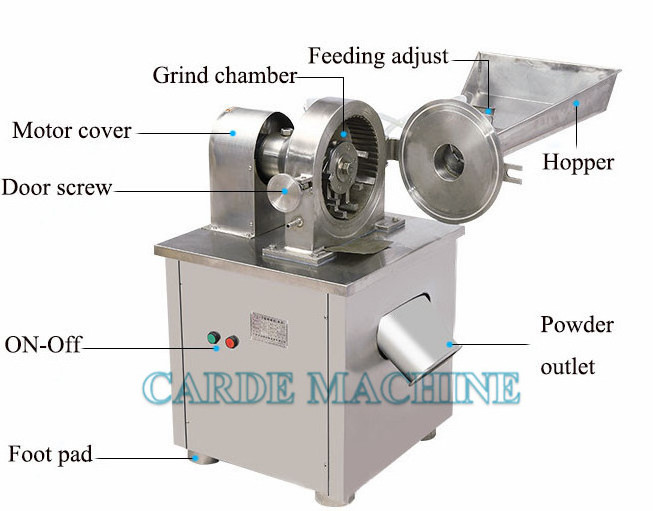

Design with larger products inlet for

receriving

raw material easily,Rounded edges easy clean

Feeding speed adjust Adjust up, faster

speed, adjust down,slower speed

Door screw, safety devices No hidden

dangers of equipment, rest assured that

the cover is equipped with an elastic

nut and a safe cover device

Water cooling device

The circulating water pipe allows

water to flow back and forth.

To cool the

machine and work well.

If need,can equip the suitable plug for better using!!!

Packing & delivery

If need other capacity,pls contact us for more details!!!

Capacity: 30-90kg/h,

50-250kg/h,

50-350kg/h Etc...

Capacity: 30-90kg/h, 3KW

Capacity: 50-250kg/h, 5.5KW

Capacity: 50-350kg/h, 7.5KW

Related Products

Hot Searches