- Product Details

- {{item.text}}

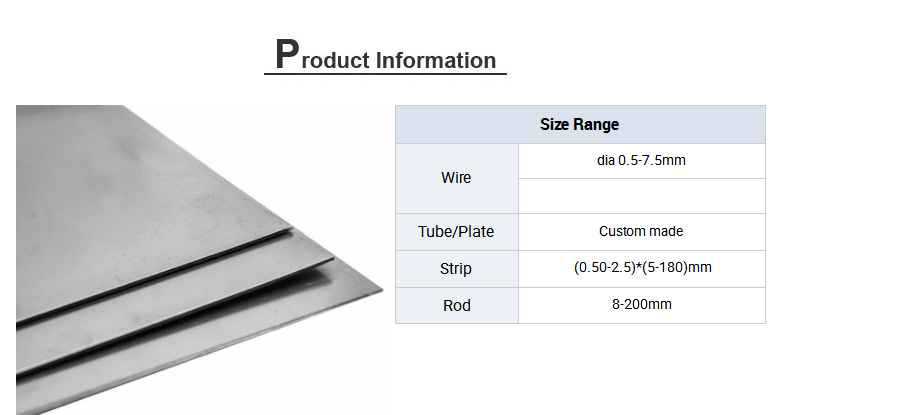

Quick Details

-

Place of Origin:

-

China

-

Application:

-

Industry

-

Grade:

-

Nickel Base Alloy

-

Ni (Min):

-

72

-

Model Number:

-

Inconel 600

-

Brand Name:

-

DZX

-

Size:

-

Customized

-

Surface:

-

bright

-

Certificate:

-

ISO,TUV

-

M.O.Q.:

-

100kgs

-

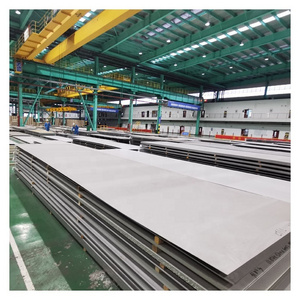

Delivery Time:

-

7 to 20 Days

Quick Details

-

Resistance (μΩ.m):

-

stable

-

Powder Or Not:

-

Not Powder

-

Elongation (≥ %):

-

30

-

Place of Origin:

-

China

-

Application:

-

Industry

-

Grade:

-

Nickel Base Alloy

-

Ni (Min):

-

72

-

Model Number:

-

Inconel 600

-

Brand Name:

-

DZX

-

Size:

-

Customized

-

Surface:

-

bright

-

Certificate:

-

ISO,TUV

-

M.O.Q.:

-

100kgs

-

Delivery Time:

-

7 to 20 Days

Inconel Alloy 600 is a nickel-chromium austenitic alloy similar to Alloy 600 but made precipitation-hardenable by additions of aluminum and titanium. It has good resistance to corrosion and oxidation along with high tensile and creep-rupture properties at high temperatures to 1300F (700degree). This material has excellent relaxation resistance and is non-magnetic. It has good elevated temperature strength properties to 1300 F (700 degree) and oxidation resistance to 1800 F (983degree). Inconel X 750 is resistant to a wide variety of industrial corrosives under both oxidizing and reducing conditions. This alloy also has excellent resistance to chloride stress corrosion cracking in the fully age hardened condition.

Alloy 600 Chemical Composition

| % | Ni | Cr | Fe | C | Mn | Si | S | P | Cu |

| min | 72 | 14 | 6 | ||||||

| max | 17 | 10 | 0.15 | 1 | 0.5 | 0.015 | 0.015 | 0.5 |

Common Applications of Alloy 600

- Structural members in hot sections of gas turbines such as discs, thrust reversers, and ducts

- Aircraft structures

- Rocket engines

- Nuclear reactors

- Heat treat fixtures

- Cryogenic vessels: springs,and fasteners

- Wire formulation with heat temper used in springs at elevated temperature