- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

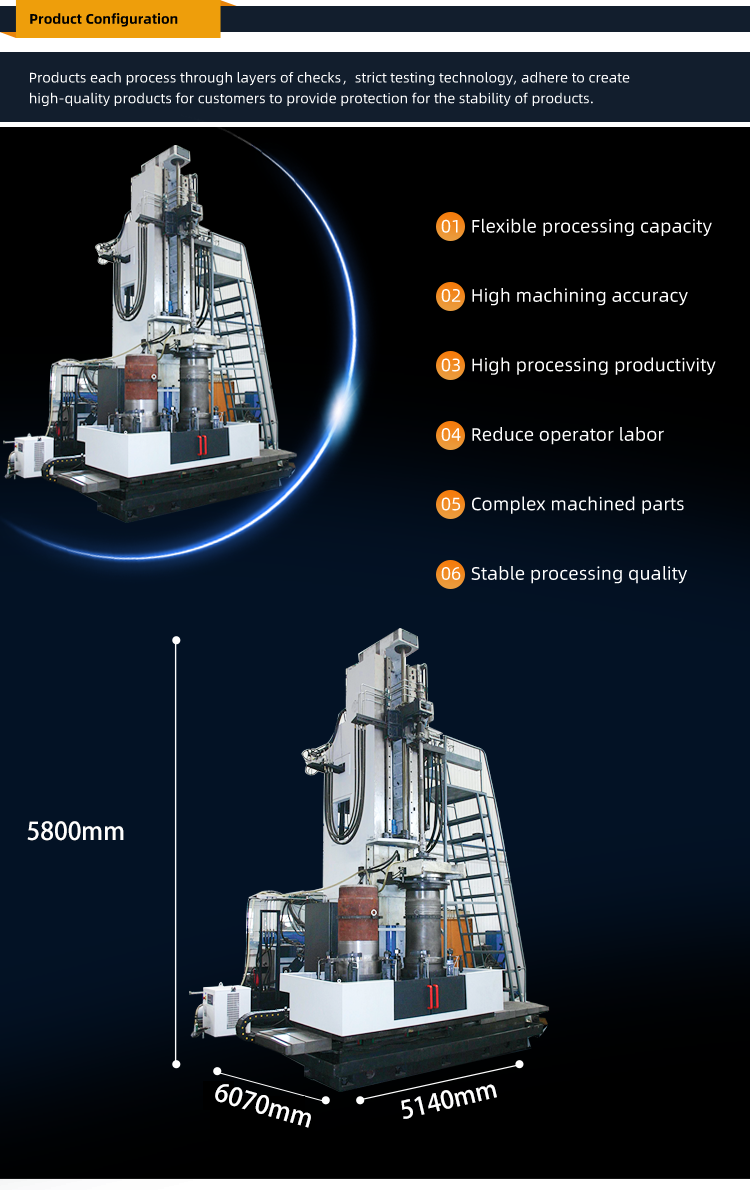

5800*5140*6070mm

-

Weight (KG):

-

15000

-

Power (kW):

-

15Kw

-

Model:

-

2MK2250X150 series

-

rang of honing dia:

-

80-500mm

-

Max.depth of honing:

-

1500mm

-

Horizontal stroke of spindle(X-axis):

-

Designed according to customer requirements

-

Spindle speeds:

-

30-200r/min

-

After-sales Service Provided:

-

Video Technical Support

-

Product Name:

-

Deep Hole Honing Machine

-

Functions:

-

Honing Engine Cylinders

-

Usage:

-

Hydraulic cylinder

-

Application:

-

Hydraulic Cylinder Repair

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Ningxia, China

-

Brand Name:

-

DAHE

-

Dimension(L*W*H):

-

5800*5140*6070mm

-

Weight (KG):

-

15000

-

Power (kW):

-

15Kw

-

Model:

-

2MK2250X150 series

-

rang of honing dia:

-

80-500mm

-

Max.depth of honing:

-

1500mm

-

Horizontal stroke of spindle(X-axis):

-

Designed according to customer requirements

-

Spindle speeds:

-

30-200r/min

-

After-sales Service Provided:

-

Video Technical Support

-

Product Name:

-

Deep Hole Honing Machine

-

Functions:

-

Honing Engine Cylinders

-

Usage:

-

Hydraulic cylinder

-

Application:

-

Hydraulic Cylinder Repair

Specification

|

Content

|

Specification

|

|

workbench area

|

1000X2000mm

|

|

The maximum diameter of honing hole

|

500mm

|

|

The maximum depth of honing

|

1500mm

|

|

Maximum reciprocating stroke of the main shaft

|

2050mm

|

|

The main shaft reciprocating minimum stroke

|

≤10mm

|

|

The spindle end face to the minimum distance

|

2610mm

|

|

The maximum distance between the spindle end face and the working table

|

4660mm

|

|

The distance between the spindle center line and the front of the column

|

500mm

|

|

The main shaft reciprocating speed

|

5 ~ 20m/min

|

|

The spindle reciprocating commutation precision

|

≤0.2mm

|

|

The spindle reciprocating commutation time

|

≤30ms

|

|

Motor power of spindle reciprocating drive

|

1.5kw

|

|

Spindle rotation speed

|

30~200r/min

|

|

Spindle motor power

|

15/18KW continuous /30 minutes

|

|

Spindle taper hole Morse

|

No. 6

|

|

Rated working pressure of main oil circuit

|

6MPa

|

|

Rated flow of main oil circuit

|

100L/min

|

|

Rated power of main oil circuit

|

18KW

|

|

Working pressure of auxiliary oil circuit

|

40MPa

|

|

Working table height from the ground

|

650mm

|

|

Work table stroke

|

1300mm

|

|

Volume of cooling box

|

710L

|

|

Cooling pump flow

|

100L/min

|

|

Cooling pump head

|

27m

|

|

The total motor power of cooling box

|

1.9KW

|

|

The total height of machine tool

|

6070mm

|

|

The machine covers a total area

|

4000X7890mm

|

|

The machine weight

|

15000Kg

|

|

For more information

|

1.

2MK2250X150 series vertical NC internal honing machine is a new generation NC honing machine developed by our company according to the national science and technology major special topic. This machine tool adopts the special honing CNC control system developed by Guangzhou CNC for our company and the special control module developed by our company, which constitutes a new international reciprocating digital control system of honing machine spindle.

2. Maximum spindle reciprocating acceleration reaches 2.5g. And obtained 8 national patents. The numerical control system can control the output of five axes.

2. Maximum spindle reciprocating acceleration reaches 2.5g. And obtained 8 national patents. The numerical control system can control the output of five axes.

3.

The whole machine

adopts modular design, which can be used for precision machining of various hydraulic cylinders, mining petroleum machinery, Marine engine cylinder hole, air compressor, compressor, cylinder liner and through hole and blind hole with aperture less than 500mm and depth less than 1500mm.

4.

This machine can not only be used in single machine, but also can be used in automatic production line of various parts. It is an ideal equipment necessary for honing processing.

DAHE NC 2MK2250X150 Vertical Honing Machine Advantages:

① Beautiful and durable. Low maintenance protective appearance provides a clean working environment and ensures operator safety.

② The machine has the function of short stroke, which can correct the individual out-of-tolerance column of the preceding sequence.

③ High degree of automatic production, can realize the connection of the production line.

The operation is simple and the maintenance is convenient.

⑤ Consumption tools, spare parts can be purchased in our factory and domestic.

⑥ Strong technical service and support.

Configuration

Hot Searches