- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

S-16H

-

Product name:

-

Automatic wire cutting&stripping machine

-

Function:

-

Automatic fixed length cutting,stripping

-

Wire size:

-

0.25-16 mm²

-

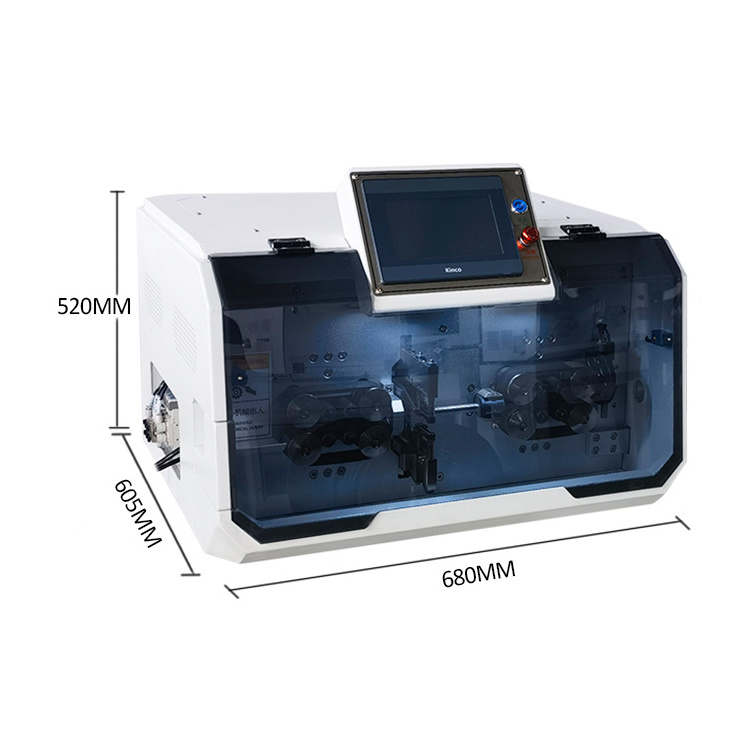

Dimension:

-

68*60*52cm

-

Cutting tolerance:

-

Within 0.002*L (L=Cutting Length)

-

Weight:

-

90kg

-

Wire type:

-

AV, MLFC, VSF, IV, KV, UL, Teflon, glass wire, etc

-

Air source:

-

0.5MPa

-

Cutting length:

-

1mm-999999.99mm

-

Power supply:

-

AC220V/110V 50/60HZ

Quick Details

-

Usage:

-

Cutting, Stripping

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

STM

-

Model Number:

-

S-16H

-

Product name:

-

Automatic wire cutting&stripping machine

-

Function:

-

Automatic fixed length cutting,stripping

-

Wire size:

-

0.25-16 mm²

-

Dimension:

-

68*60*52cm

-

Cutting tolerance:

-

Within 0.002*L (L=Cutting Length)

-

Weight:

-

90kg

-

Wire type:

-

AV, MLFC, VSF, IV, KV, UL, Teflon, glass wire, etc

-

Air source:

-

0.5MPa

-

Cutting length:

-

1mm-999999.99mm

-

Power supply:

-

AC220V/110V 50/60HZ

High Efficiency Electric Wire Stripper and Cable Cutter 0.25-16mm2 Wire Cutting Machine Stripping efficiency up to 5000pcs/H

Our wire cutting and stripping machines are used for fully automatic fixed length cutting and stripping of all kinds of cables.

100 sets of processing parameters and schemes can be stored and supports multiple languages.

The blade holder adopts servo motor, stable performance, so that the wire cut is smooth and the service life is long. The blade material is imported steel, the cutting speed is fast.

Suitable for all kinds of cables, flat wires, multi-core sheathed cables, shielded cables, etc both ends stripping, inner core wire both ends stripping, twisted wires, middle multi-section stripping, internal parts can be replaced according to your needs, a variety of functions are optional.

Our wire cutting and stripping machines are used for fully automatic fixed length cutting and stripping of all kinds of cables. 100 sets of processing parameters and schemes can be stored. The blade holder adopts servo motor, stable performance, so that the wire cut is smooth and the service life is long. The blade material is imported steel, the cutting speed is fast. Suitable for all kinds of cables, flat wires, multi-core sheathed cables, shielded cables, etc both ends stripping, inner core wire both ends stripping, twisted wires, middle multi-section stripping, internal parts can be replaced according to your needs, a variety of functions are optional.

| Automatic wire harness cut and strip machine | ||

| Model | S-35 | S-16H |

| Processing Range | 0.25-35mm² | 0.25-16mm² |

| Allowed wire diameter | Max Φ18mm | Max Φ12mm |

| Production Rate | 3500pcs/hour | 5500pcs/hour |

| Display | 7 Inch touch screen, supports multiple languages | |

| MOQ | 1 Set | |

| Customized | MOQ 1 Set For Customized Version | |

| Function | Single-core cable, multi-core cable, shielded cable, wire, Automatic fixed length cutting, stripping,built-in manipulator wire clamp | |

| Wire Type | Single-core cable, multi-core cable, shielded cable, wire,PVC,etc | |

| Cutting Length | 1mm---99999.99mm | |

| Cutting Tolerance | Within 0.002*L (L=Cutting Length) | |

| Stripping length | Front end full off:1-200mm, front end half off: 1-1500mm | |

| Raer end full off:1-100mm, raer end half off: 1-300mm | ||

| Tool Material | High quality imported high speed steel | |

| Production Rate | 3500pcs/hour (depending on the length and size of the wire) | |

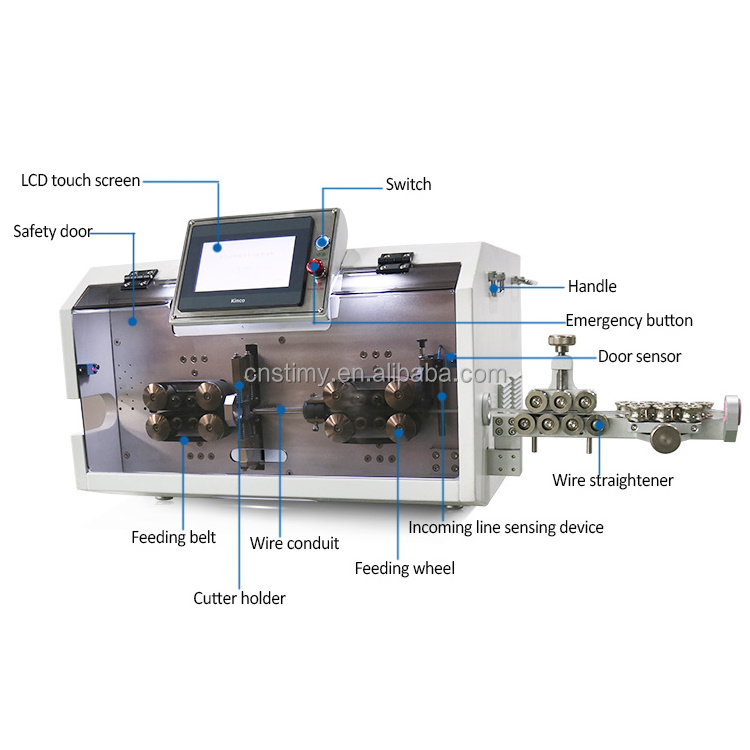

| Drive Mode | 16-wheel drive ( Feed stepper motor, blade holder servo motor ) ; Servo Motor Optional | |

| Feeding System | Belt Feeding, No embossing or scratches on the wire(with stripping pressure function) | |

| Lifting Operation Mode | Digital Adjustment of pressure wheel/roller height | |

| Power Supply | AC220v 50/60Hz; Optional: 110v 50/60Hz | |

| Air Source | 0.5Mpa clean air source | |

| Dimension | 680*605*520mm | |

| N.W | 90KG | |

| Warranry | 1 year | |

Feature:

1, Optional: MES system, Internet of Things system, fixed-point inkjet function, mid-stripping function, external auxiliary equipment alarm;

2, User-friendly system, intuitive operation via 7-inch color touch screen;

3, Modular interface, convenient for linking accessories and peripheral equipment;

4, Modular design, future upgradeable;

5, A variety of additional options can customize the system. Special pipe processing can be customized

If you want to know more details about wire processing machinery, please click here to contact us .