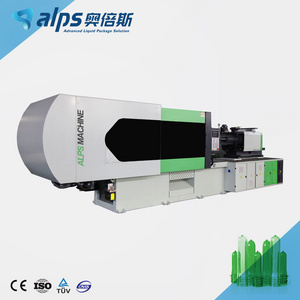

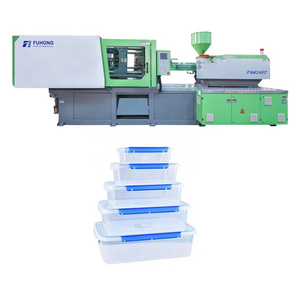

A plastic injection molding machine is a machine used to manufacture plastic products. It uses an injection molding process to inject heated and molten plastic into the mold cavity through an injection system. After cooling and solidifying, the required plastic products are obtained.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Product name:

-

Plastic Injection Moulding Machine

-

Application:

-

Widely Used

-

Maximum mold thickness:

-

580MM

-

Injection pressure:

-

16MPA

-

Plasticizing ability:

-

253g/s

-

Screw speed:

-

0-170

-

clamping force:

-

1600KN

-

Mold transfer stroke:

-

540MM

-

Internal spacing of tie rods:

-

580*580

-

Ejection stroke:

-

40MM

Quick Details

-

Injection Rate (g/s):

-

253 g/s

-

Injection Weight (g):

-

1566 g

-

Weight (KG):

-

8400 kg

-

Place of Origin:

-

Guangdong, China

-

Product name:

-

Plastic Injection Moulding Machine

-

Application:

-

Widely Used

-

Maximum mold thickness:

-

580MM

-

Injection pressure:

-

16MPA

-

Plasticizing ability:

-

253g/s

-

Screw speed:

-

0-170

-

clamping force:

-

1600KN

-

Mold transfer stroke:

-

540MM

-

Internal spacing of tie rods:

-

580*580

-

Ejection stroke:

-

40MM

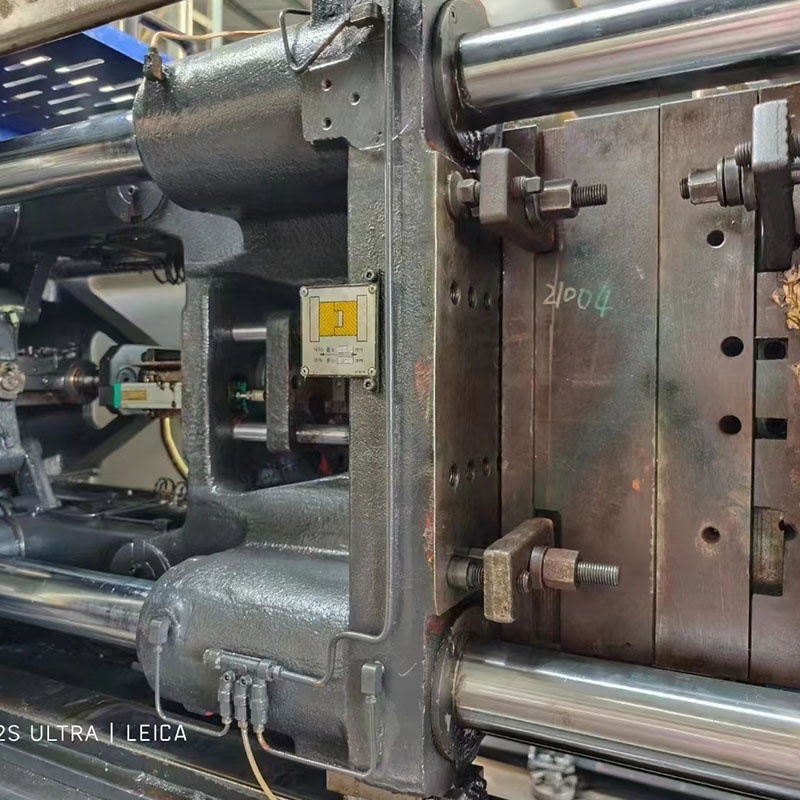

used plastic injection molding machine

Product introduction

|

Model

|

MA1600II/540

|

|

|

||

|

Mold clamping force

|

1600kn

|

|

|

||

|

Injection volume

|

253cm

3

|

|

|

||

|

Power supply

|

AC380V3P/N/PE50HZ

|

|

|

||

|

Current

|

53.9A

|

|

|

||

|

Factory date

|

2018-09-25

|

|

|

||

|

Screw diameter

|

40 mm A

|

|

|

||

|

Total power

|

24.75kw

|

|

|

||

|

Implementation standard

|

Q/NHTJ062-2016

|

|

|

||

Machine detail photos

Product advantage

High-Quality Manufacturing: Using advanced manufacturing technology and high-quality materials to ensure product reliability and durability. Its machines have stable performance and excellent durability, and can meet long-term, high-intensity production needs.

Advanced technological innovation: committed to technological innovation and research and development, and constantly introducing advanced injection molding technology and equipment. They pay attention to the latest trends in the industry and apply innovation to product design and manufacturing to improve production efficiency, reduce energy consumption and optimize product quality.

Extensive Product Line: Injection Molding Machine offers a variety of models and specifications of injection molding machines to meet the needs of different customers. Whether it is a small or large injection molding machine, whether it is used for plastic container production, automotive parts or electronics manufacturing, we have the right solution.

Customer customization service: Injection molding machines focus on cooperation with customers and provide personalized customization services. They are able to customize and design injection molding machines suitable for their production needs according to their specific requirements to ensure that customers can obtain the best production results and economic benefits.

Good after-sales service: Injection molding machines focus on after-sales service and provide timely and professional technical support and maintenance services. They have an extensive after-sales network and a professional technical team that can quickly respond to customer needs, solve possible problems, and ensure that customers' production goes smoothly.

Application

Plastic injection molding machines are widely used to manufacture various plastic products, such as plastic containers, plastic parts, plastic packaging, etc. It has the advantages of high production efficiency, high product precision, short production cycle, and strong plasticity, so it is widely used in modern industrial production.

Why Choose Us

FAQ

1. Who are we? We are based in Guangdong, China and have been selling to the Middle East (40.00%), North America (20.00%),

Southeast Asia (20.00%), and East Asia (20.00%) since 2011. We have a total of 11-50 people in our office.

2. How can we guarantee quality?

Before mass production, there is always a pre-production sample. There is always a final inspection before shipment.

3.What can you buy from us?

Vacuum thermoforming machine, small plastic box vacuum forming machine, used sheet extruder, PET/PP/PS thermoforming machine,

plastic folding and packing machine for blister shells and other plastic equipment.

4. Why should you buy from us instead of other suppliers?

We are engaged in professional vacuum blister machine, small automatic vacuum blister machine, used sheet extrusion machine,

thick board machine, blister folding machine, plastic heat seal packaging machine and other plastic

equipment.

5.What services can we provide?

Accepted delivery terms. FOB,CFR,CIF,EXW,FAS,FCA,DDP,DDU;. Accepted payment currencies:

USD, EUR, JPY, CAD, AUD, HKD, GBP, RMB, CHF. Accepted payment methods: T/T, L/C, credit card, PayPal.

Language:English,Chinese,Italian

Southeast Asia (20.00%), and East Asia (20.00%) since 2011. We have a total of 11-50 people in our office.

2. How can we guarantee quality?

Before mass production, there is always a pre-production sample. There is always a final inspection before shipment.

3.What can you buy from us?

Vacuum thermoforming machine, small plastic box vacuum forming machine, used sheet extruder, PET/PP/PS thermoforming machine,

plastic folding and packing machine for blister shells and other plastic equipment.

4. Why should you buy from us instead of other suppliers?

We are engaged in professional vacuum blister machine, small automatic vacuum blister machine, used sheet extrusion machine,

thick board machine, blister folding machine, plastic heat seal packaging machine and other plastic

equipment.

5.What services can we provide?

Accepted delivery terms. FOB,CFR,CIF,EXW,FAS,FCA,DDP,DDU;. Accepted payment currencies:

USD, EUR, JPY, CAD, AUD, HKD, GBP, RMB, CHF. Accepted payment methods: T/T, L/C, credit card, PayPal.

Language:English,Chinese,Italian

Hot Searches