- Product Details

- {{item.text}}

Quick Details

-

Return Force (kN):

-

12 kN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhongyou

-

Year:

-

2022

-

Voltage:

-

380V/220V Optional

-

Dimension(L*W*H):

-

270X250X380 cm

-

Weight (T):

-

12 T

-

Motor Power (kw):

-

22 kw

-

Product name:

-

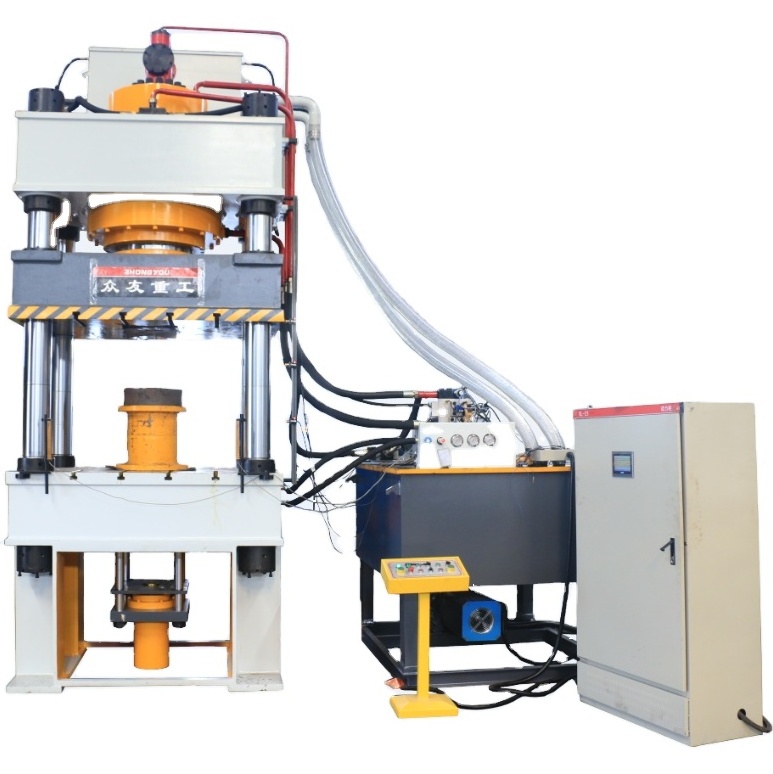

hydraulic press machine

-

Application:

-

stainless steel kitchen sink making machine

-

Function:

-

make steel kitchen sink

-

Type:

-

Four Columns

-

Material:

-

Steel Material Hydraulic Press Machine

-

Model:

-

YQ32 hydraulic press machine

-

Servo motor:

-

customizable

-

Name:

-

Hydraulic Press machine

-

Power souce:

-

Hydraulic Press Machine

-

Brand:

-

CNZY

Quick Details

-

Machine Type:

-

Four-column Three-beam Hydraulic Press

-

Slide Stroke (mm):

-

200

-

Ejector Force (kN):

-

200

-

Return Force (kN):

-

12 kN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhongyou

-

Year:

-

2022

-

Voltage:

-

380V/220V Optional

-

Dimension(L*W*H):

-

270X250X380 cm

-

Weight (T):

-

12 T

-

Motor Power (kw):

-

22 kw

-

Product name:

-

hydraulic press machine

-

Application:

-

stainless steel kitchen sink making machine

-

Function:

-

make steel kitchen sink

-

Type:

-

Four Columns

-

Material:

-

Steel Material Hydraulic Press Machine

-

Model:

-

YQ32 hydraulic press machine

-

Servo motor:

-

customizable

-

Name:

-

Hydraulic Press machine

-

Power souce:

-

Hydraulic Press Machine

-

Brand:

-

CNZY

Aluminium pot making cookware making pan making deep drawing press manufacturer

A deep drawing press is a type of mechanical press machine used in metalworking operations to produce parts with a deep, cup-shaped geometry. The process involves using a punch and die set to deform a flat sheet of metal into a hollow shape with a depth greater than its diameter.

|

MODEL |

YQ32-315T |

YQ32-500T |

YQ32-630T |

|

Nominal force |

315T |

500T |

630T |

|

Liquid working pressure(MPa) |

25 |

25 |

25 |

|

Nominal pressure(KN) |

3150 |

5000 |

6300 |

|

Master cylinder stroke(mm) |

500 |

500 |

500 |

|

Max. opening height(mm) |

1260 |

1260 |

1300 |

|

Lifting cylinder(T) |

30*2 |

50*2 |

50*2 |

|

Lifting cylinder stroke(mm) |

400 |

400 |

400 |

|

Working table size(mm*mm) |

1000*1000 |

1000*1000 |

1200*1200 |

|

Descent speed(mm/s) |

250 |

246 |

220 |

|

Working speed(mm/s) |

10~20 |

10~20 |

10~20 |

|

Return speed(mm/s) |

130 |

170 |

140 |

|

Motorpower(KW) |

22 |

18.5*2 |

22*2 |

-

Strong and sturdy construction : Deep drawing press machines are typically made from heavy-duty steel frames and cast iron components to withstand the high forces involved in the metal drawing process.

High-pressure hydraulic or mechanical systems : The press machine must generate high pressure to draw the sheet metal into the die cavity. Hydraulic systems use pressurized oil to create the force, while mechanical systems use a crankshaft or toggle mechanism.

-

Multi-stage drawing capability : Most deep drawing press machines are designed to perform multi-stage drawing processes to create more complex parts. This involves multiple stages of drawing using different dies to gradually shape the metal into the desired form.

Versatility : Deep drawing press machines can be customized for different types of sheet metal, including aluminum, brass, copper, and steel. They can also be equipped with different dies and tooling to create parts of varying sizes and shapes.

Automation and safety features : Many modern deep drawing press machines feature automation and safety features to increase productivity and prevent accidents. For example, sensors can detect if a part is not positioned correctly and stop the machine to prevent damage to the tooling or the part.

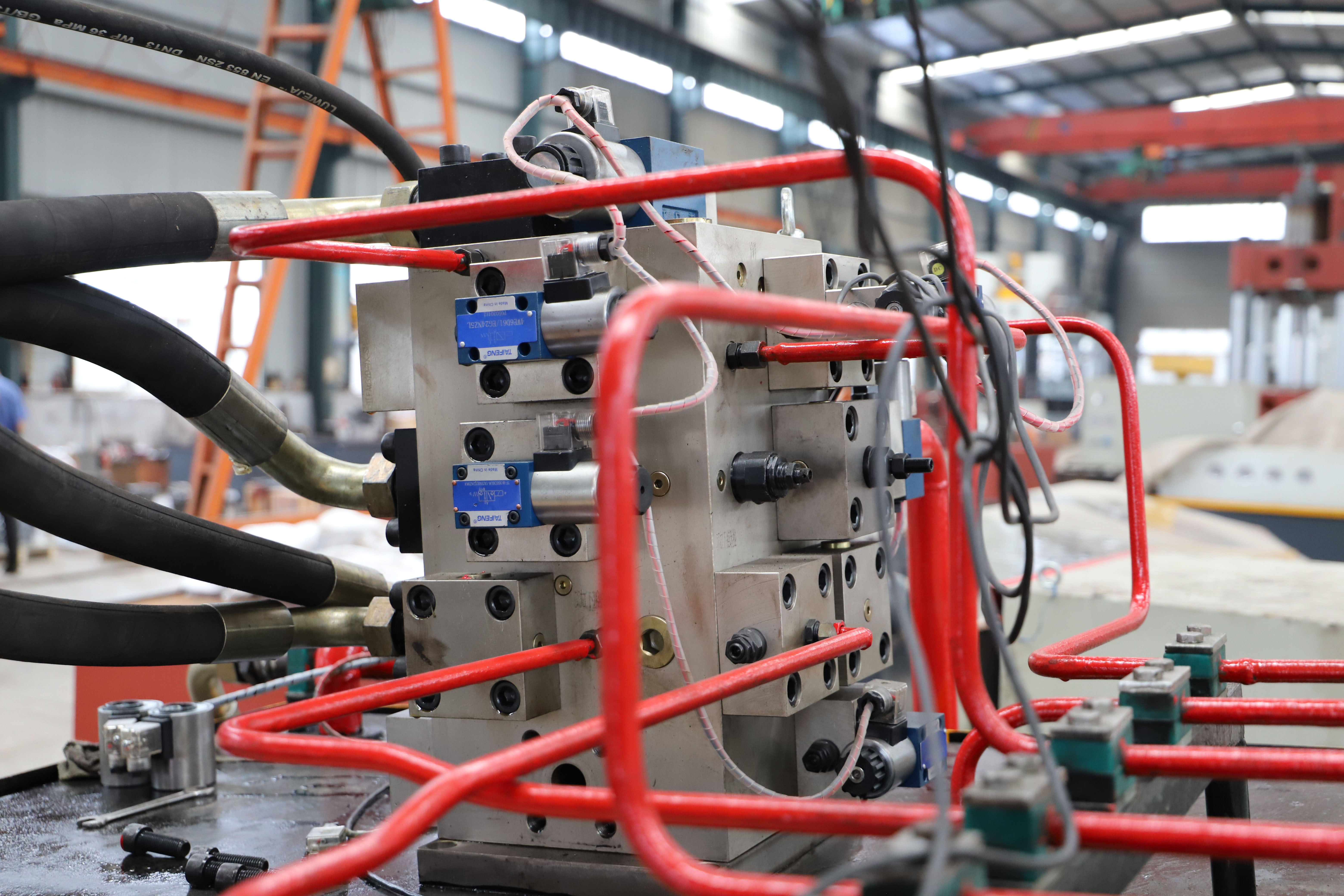

- Hydraulic pipe system uses integrated

circuits - manifold block fits inside the

press to reduce piping and oil leaks,

easy to maintain, simple and safe.

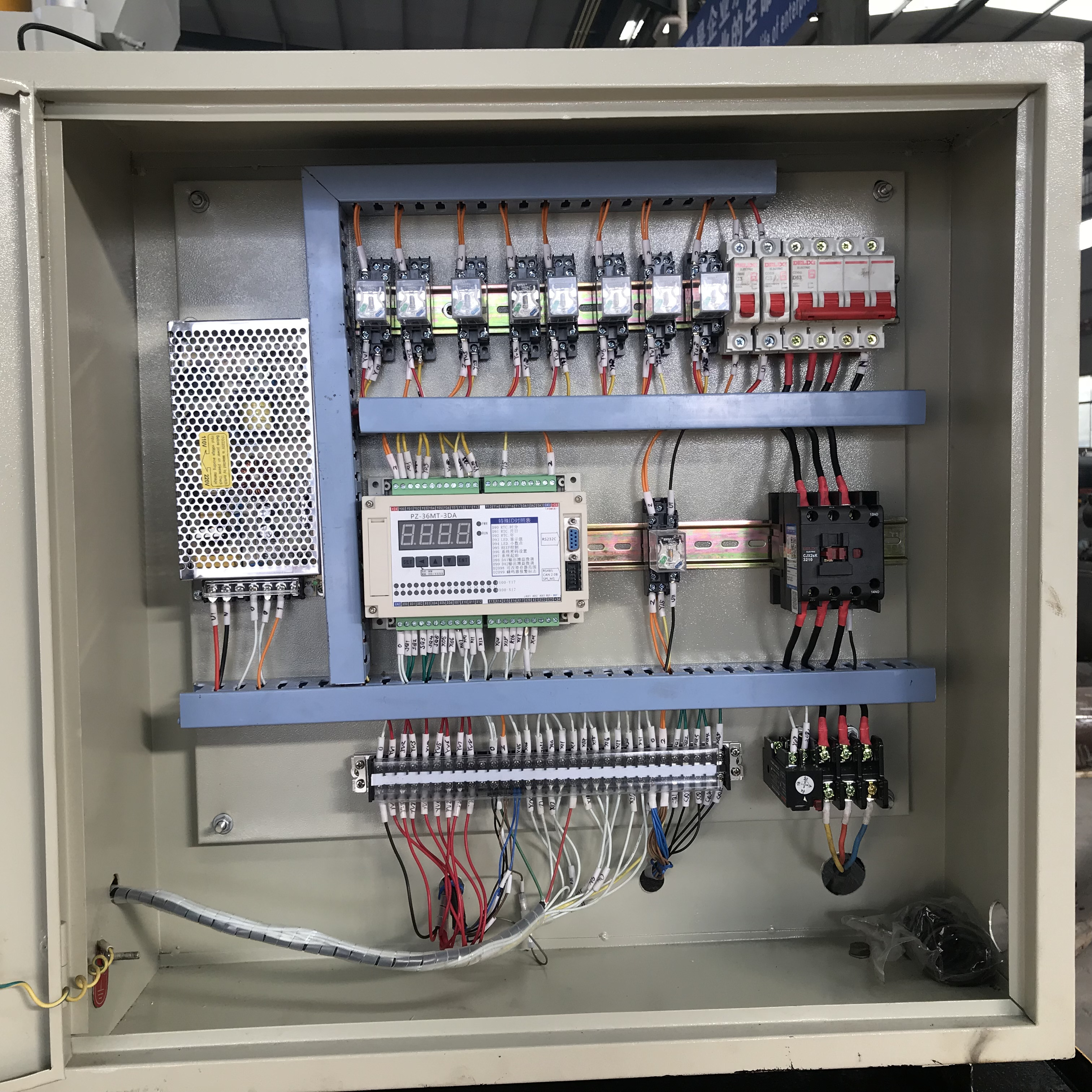

- All our electrical, hydraulic and mechanical parts

meet the standard in the industry and available

throughout North America and Europe.