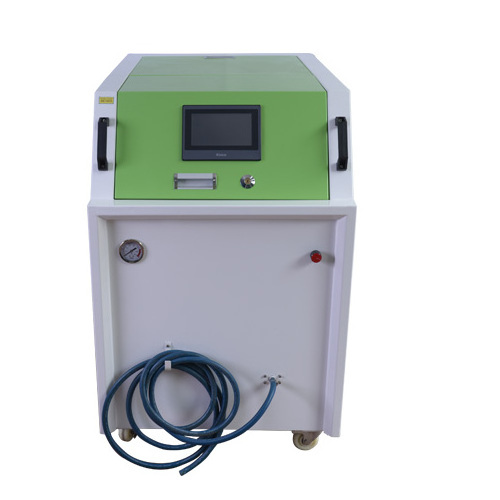

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 3 phases

-

Weight:

-

210 KG

-

Dimension(L*W*H):

-

1070*670*1000mm

-

Max gas output:

-

2000L/h

-

Max power consumption:

-

6KW/H

-

Max working pressure:

-

0.2Mpa

-

Application:

-

jewelry welding, car carbon cleaning, ampoules sealing etc

-

Advantages:

-

energy saving,environmental friendly,safety

-

Color:

-

green

-

Water feed:

-

automatic

-

Working Medium:

-

pure water

-

Flame Temperature:

-

2800 degree

Quick Details

-

Warranty:

-

1 Year

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Okay Energy

-

Voltage:

-

380V, 3 phases

-

Weight:

-

210 KG

-

Dimension(L*W*H):

-

1070*670*1000mm

-

Max gas output:

-

2000L/h

-

Max power consumption:

-

6KW/H

-

Max working pressure:

-

0.2Mpa

-

Application:

-

jewelry welding, car carbon cleaning, ampoules sealing etc

-

Advantages:

-

energy saving,environmental friendly,safety

-

Color:

-

green

-

Water feed:

-

automatic

-

Working Medium:

-

pure water

-

Flame Temperature:

-

2800 degree

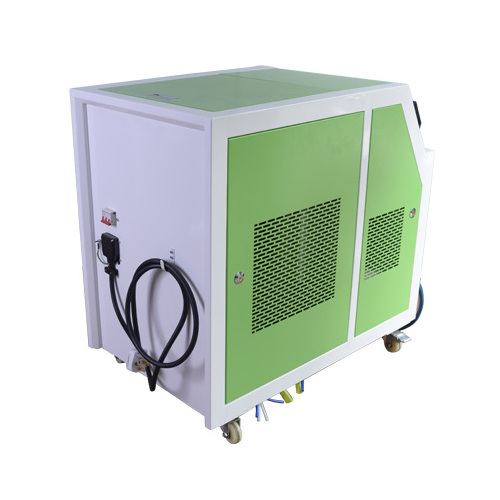

hho hydrogen generator fuel saver hho generator for boiler

L arge Indurstrial

|

Model Number |

OH2000 |

OH3000 |

OH5500 |

OH7500 |

OH10000 |

|

AC Voltage Requirement(V) |

380 |

380 |

380 |

380 |

380 |

|

Phase |

3 phase |

3 phase |

three phase |

3 phase |

3 phase |

|

Rated Power(kw/h) |

4.5 |

9 |

17 |

23 |

31 |

|

Max. Gas Output(L/h) |

1500(adjustable) |

30 00(adjustable) |

5 5 00(adjustable) |

7 5 00(adjustable) |

97 00(adjustable) |

|

Max. Working Pressure(kg/cm 2 ) |

2 |

2 |

2 |

2 |

2 |

|

Max. Water Consumption (L/h) |

0.9 |

1.8 |

2.8 |

4 |

5.6 |

|

Water Feed |

auto |

auto |

auto |

auto |

auto |

|

Dimensions-L*W*H(mm) |

1 07 0* 67 0*1 0 00 |

1 070 * 67 0*1 5 00 |

1 2 00* 67 0*1 70 0 |

1 3 50* 67 0*1 8 00 |

15 0 0* 67 0*1 80 0 |

|

Gross Weight(kg) |

280 |

330 |

396 |

552 |

610 |

|

Ventilation Space Requirement(mm) |

400 in each direction |

400 in each direction |

400 in each direction |

400 in each direction |

400 in each direction |

Oxyhydrogen/Oxy-hydrogen Generator/ hho hydrogen generator fuel saver hho generator for boiler

- Energy-saving. Oil saving 20%,Energy saving 40% . Consume water and electricity, electrolyze water into hydrogen gas and oxygen gas. Use H2 and O2 as source of flame replacing LPG, Propane, Acetylene fuel or natural gas or other fuel.

- Environment-friendly. Consumption of water, produce of water. Compared with traditional fuel, and are more beneficial to the environment and human.

3. 100% safe. Because the density of hydrogen is small, will not assembled on the ground,

so there is no risk of explosion.

4. Save time & money. The temperature of the oxyhydrogen flame is up to 2800 degrees Celsius,and

the flame is more concentrated. Compared with conventional fuel, more save time and cost.

More applications of Oxyhydrogen Generator/Oxy-Hydrogen generator

1.Welding

(1) Electronic Industry:

For welding enameled wire, computer wire peeling, LED wafer, flame-treating circuit board thermocouple and platinum resistor leading wires.

(2) Medical Industry:

For denture welding. For welding metal fittings and mending sand holes in dentistry.No-carbon flame disinfection and glass seal.

(3) Laboratory:

For welding of laboratory teaching, providing convenient, safe and clean oxy-hydrogen flame.

(4) Jewelry Industry

For welding kinds of chain and string which are made of platinum, gold, silver, copper, stainless steel, etc. For mending tiny sand holes on jewelry casting and jewelry repairing(reforming,casting,welding).

(5) Others:

Instrument welding, Air-condition copper pipe welding, Automobile exhaust pipe welding, Fishhook welding, Storage battery tinplate welding, lighting hardware welding and etc.

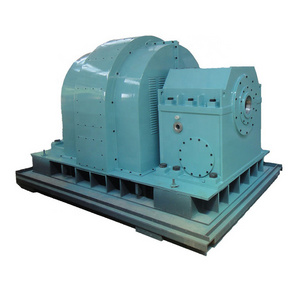

2.Cutting

Large oxyhydrogen generator/HHO generator can be widely used in Carbon Steel Cutting and continuous casting slab cutting of steel plant. It can be cooperate with manual cutting torch,semi-automatic cutting machine, shape cutting machine, CNC cutting machine to instead of traditional fuel gas.

3.Heating and Sealing

(1) metal and nonmetal heating

(2) glass tube sealing, quartz glass tube sealing

(3) ampoule bottles sealing

(4) water injection drawing sealing

(5) mould repair, quenching crucible heating melting metal

(6) solar wafer processing, IC packaging

4.Polishing:Organic glass/Acrylic polishing

5.Others :

For welding or Heat treating small metal parts, Iron Cutting, Catalytic combustion of other fuels, Engine carbon cleaning for automobiles.

Why choose Okay oxyhydrogen generator/Oxy-hydrogen generator?

1.The most important reason, we are more professional than any other company.

Unique Patented 8 Systems Features of Okay Energy Oxyhydrogen Generator/ Oxy-Hydrogen generator compared with others:

|

|

Okay Energy Oxyhydrogen Generator/ Oxy-Hydrogen generator |

Other manufacturers |

|

1.Power Supply |

IGBT frequency conversion technology, conversion efficiency is as high as above 90%, stable and reliableto exchange AC turn to DC. |

Silicon controlled rectifier or MOS tube rectifier technology, low efficiency to AC to DC. Unstable Current causes the gas production is not stable. |

|

2.Electrolysis cell |

Integration formed electrolysis cell, no any gas and liquid leakage. |

Adopts in Series, piece together way, there is one seal ring between each polar plate to prevent gas and liquid from leakage. Each electrolysis cell have dozens of sealing rings, the cell cannot work as long as there is one seal occur leakage. |

|

3.Electrolytic process

|

Dynamic self-circulation electrolytic process, purifier is installed in electrolyte circulation pipeline, it can clean the electrolysis cell automatically. |

Static electrolysis process, the cell is easy to be dirty, some of the manufacturers use dynamic electrolytic system, but there is no automatic cleaning filtering device. |

|

4.Electrolysis polar plate

|

Special activity alloy material surface treatment, low overpotential and no leakage between the polar plates, the gas production efficiency is high.

|

Using the method of drilling in plate to realize the gas and liquid flow, these holes with gas and liquid flowing can cause leakage of currents, the gas production efficiency is low.

|

|

5.Moisture separation system |

Centrifugal compulsive moisture separation device, can achieve Moisture separation 100%, and always keep blue flame.

|

Using gravity to do separation of moisture. It can’t do separation completely due to the hydrogen and oxygen gas flow fast. The cell temperature will rise after long time using, the moisture content will increase in oxy-hydrogen gas, then the flame will be red, flame temperature will be lower. |

|

6.Pipeline system |

seamless stainless steel tube, no any rubber hoses absolutely, no gas or liquid leakage, ensures the safety and reliability |

Using PU hose more or less to connect gas path.It will appear gas or liquid leakage phenomenon after a period of time in using or after backfire. |

|

7.Anti-backfire system |

Adopt patented wet-type anti-backfire and dry-type flashback arrestor and automatic safety valve device, build in automatically decompression and recover device, prevent from backfire, no need reset by manual. |

Adopt dry-type arrestor to prevent backfire, if backfire happens it needs to reset by manual. After several backfire, the rubber gasket in arrestor will damaged, flashback arrestor will lost effectiveness. |

|

8.Heat dissipation system |

Unique duct design and larger space for heat dissipation to meet the needs of the work for 24 hours under high temperature of 40 degrees in summer. |

The internal device is installed close, less space for heat dissipation, bad cooling in summer. It will result in:(1) shut down automatically for thermal protection (2) moisture with gas to reduce the flame temperature, affect product quality. |