- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

110-500KW

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

12000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product:

-

arge area glass coating system

-

Business type:

-

China manufacture

-

glass size:

-

2540 mm * 3360 mm, 3300 mm * 6000 mm

-

Brand:

-

HCVAC

-

Layer:

-

silver film,sunshine film,low-E,ITO, AZO, AR, Ag,

-

coating time:

-

40s to 120s per piece

-

Application:

-

photovoltaics,Low-e glass,ZnO,LCD,construction glass,

Quick Details

-

Machine Type:

-

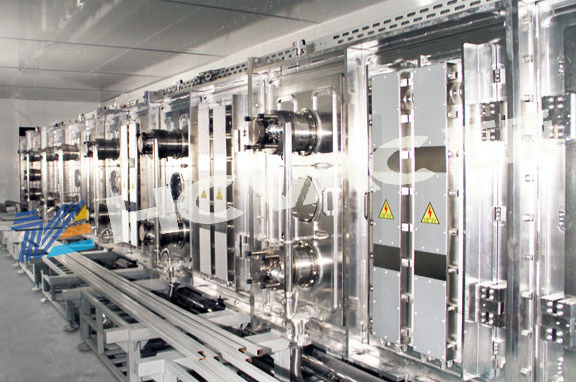

pvd vacuum coating machine, Coating Equipment, vacuum caoting machine, pvd machine

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HCVAC

-

Voltage:

-

380V

-

Power:

-

110-500KW

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

12000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product:

-

arge area glass coating system

-

Business type:

-

China manufacture

-

glass size:

-

2540 mm * 3360 mm, 3300 mm * 6000 mm

-

Brand:

-

HCVAC

-

Layer:

-

silver film,sunshine film,low-E,ITO, AZO, AR, Ag,

-

coating time:

-

40s to 120s per piece

-

Application:

-

photovoltaics,Low-e glass,ZnO,LCD,construction glass,

HCVAC Inline PVD Sputtering System Pvd Vacuum Sputtering Coating Line ITO Glass Coating Machine

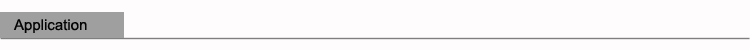

Continuous Magnetron Sputtering Coating production line of HC company is the industry's striking vacuum coating technology production lines, high performance, high efficiency and reliable stability.

Breakthrough Innovation and Technology

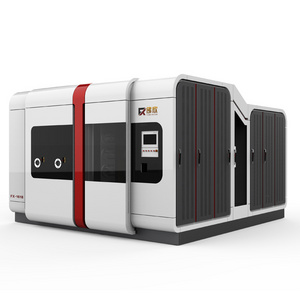

1. Coating based on the world's most popular rotating cathode, sputtering rate greatly increased, while usage of target has increased by 200% or more. Effectively reducing the production cost.

2. Using the most advanced infrared heating system in the world, the system can achieve short heating time,fast heating up, energy consumption is less than 1/3 of conventional heating pipe. The ordinary heat pipe vacuum chamber evenly heated to 400 °C need 2-3 hours at least with constantly heated.However, because of the special circumstances of the vacuum chamber and infrared heating tube targeted design, you can complete vacuum chamber preheating process within 1-1.5 hours.

- HCVAC Continuous Magnetron Sputtering Coating production line is mainly used in touch screen, acrylic, glass, ceramics, mobile shell, computers, PET, etc.. Coated high-quality, high-performance metal film, electromagnetic shielding film, reaction film, composite film, the transparent conductive film, radiation (AR), the reflection-increasing film, LOW-E film, etc.

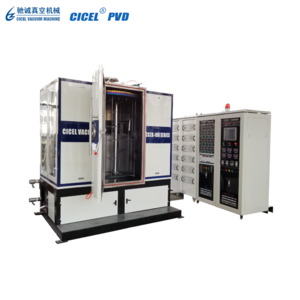

- Our company can provide the design in demand of customer.At present, products and process throughout the country and overseas.

- Whether it be architectural glass for facades, large display screens or special coatings, in all these cases large substrates are coated and millions of square meters receive highly complex functional layers which ultimately provide the desired properties. Piece by piece and with the highest precision and repeatability.

- HCVAC provides the equipment to master the challenges of large-area coating for the applications mentioned above and many more. Modular design, optimized processes, energy efficiency, high throughput and accurate quality control are just some of the features you can expect from us.

- Whatever your large-area application may be, HCVAC has the solution: from giant architectural glass coaters via precision display coating machines to sophisticated laboratory equipment.

- The coating experts of your own company : Full set solution for the coating production.