- Product Details

- {{item.text}}

Quick Details

-

Certification:

-

CE, ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

name:

-

Dry Drum Magnetic Separator for Chrome Ore Beneficiation

-

Certification:

-

CE, ISO

Dry Drum Magnetic Separator for Chrome Ore Beneficiation

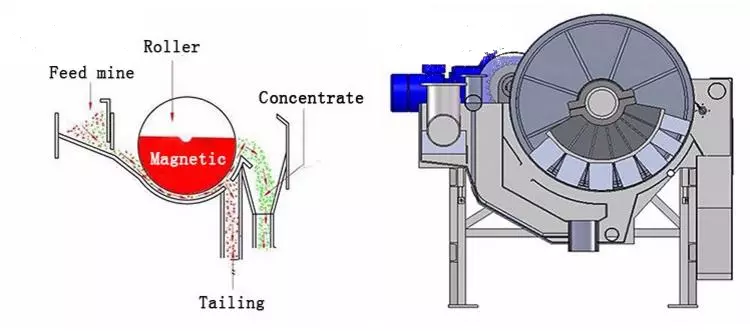

Brief Introduction

Magnetic separator is widely used in mineral processing, coal washing and chemical industry, for sorting the wet particle size of 6-10mm. The strong magnetic minerals and magnetic minerals are divided into two kinds of material: non-magnetic material and magnetic material. Magnetic separator is suitable for wet magnetic separation of materials such as magnetite, calcined ore, etc. and it can remove the iron in the coal, non-metal and construction industries.

The magnetic system is made from high quality ferrite magnetic materials or rare earth magnet steel. On the shell surface, the magnet intensity is 100-600mT. The wet type permanent magnet cylindrical separator is commonly used for iron ore separation. It is suitable for separating materials with high magnetism. In recent years, it has been used as the concentrating equipment in place of magnetic dewatering cell.

When the raw materials flow into the tank body of the wet drum magnetic separator, firstly, the flowing direction of the raw materials is the same as the rotary direction of the magnetic drum, the iron magnetite materials are attracted to the surface of drum. This is the first separation. In the second step, the flushing water below flush the raw materials back for the second separation. This time the flowing direction of the raw materials is opposite to the rotary direction of the magnetic drum. Then along with the rotation of drum, the iron magnetite materials on the surface of drum will finally leave the magnetic field and fall to the ore concentrate box under gravity. Also, the flushing water above helps to flush the iron magnetite into the ore concentrate box. The weak magnetic and non-magnetic materials cannot be attracted and will flow to the discharge pipe for tailings.

The magnetic system of magnetic separator integrates good-quality iron-oxide body materials with rare earth magnetic steel; the average magnetic induction intensity of cylinder surface is 100-600mT. According to the needs of customers, the magnetic separator can be co-current, half-countercurrent, countercurrent, and so on. The magnetic separator has the advantages of simple structure, big processing volume, convenient operation and easy maintenance, etc.

| Model | Shell Diameter (mm) | Shell length (mm) | Feed size (mm) | Capacity (t/h) | Power(kw) | Weight (t) |

| CTB612 | Φ600 | 1200 | 0-2 | 10-20 | 1.5 | 1.5 |

| CTB618 | Φ600 | 1800 | 0-2 | 15-30 | 2.2 | 1.8 |

| CTB718 | Φ750 | 1800 | 0-2 | 25-45 | 3.0 | 2.2 |

| CTB918 | Φ900 | 1800 | 0-3 | 35-70 | 4.0 | 2.8 |

| CTB1018 | Φ1050 | 1800 | 0-3 | 40-75 | 5.5 | 4.3 |

| CTB1024 | Φ1050 | 2400 | 0-3 | 52-100 | 5.5 | 5.2 |

| CTB1218 | Φ1200 | 1800 | 0-3 | 47-90 | 5.5 | 5.0 |

| CTB1224 | Φ1200 | 2400 | 0-3 | 80-120 | 7.5 | 6.4 |

Any change of technical parameters, there is no further notice.