- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hightop

-

Model Number:

-

ISO and Poly

-

Type:

-

two component

-

MOQ:

-

1 set

-

Delivery time:

-

within 3-7 days

Quick Details

-

CAS No.:

-

other

-

MF:

-

other

-

EINECS No.:

-

other

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hightop

-

Model Number:

-

ISO and Poly

-

Type:

-

two component

-

MOQ:

-

1 set

-

Delivery time:

-

within 3-7 days

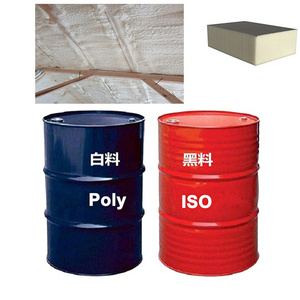

High Density Polyurethane PU Foam Reinforced Strength Black Liquid Flexible PU Rigid Foam Expanded Fire Proof Suppliers

Noted: Our product performance and model are constantly updated and may not be displayed on the website in time. If you are interested in our products, please contact our sales person or send email to get the latest product information.

Product Description

rigid polyol prix and isocyanate polyurethane spray foam is spray blend polyols, it reacts with isocyanate to produce foam which has excellent performances, which are as follows,

1) fine and uniformity cells

2) low thermal conductivity

3) perfect flame resistance

4) good low temperature dimentional stability.

It applies to all kinds of thermal insulation engineering which uses the spray technology, such as cold rooms, pots, large-scale pipelines and construction metope etc.

Physical Properties

|

Appearance |

|

Pale yellow to brown viscous liquid |

|

Hydroxyl Value |

mgKOH/g |

200-300 |

|

Dynamic Viscosity (25 ºC) |

mpa.s |

300-500 |

|

Specific gravity (20 ºC ) |

g/ml |

3.12-3.20 |

|

Storage Temperature |

ºC |

10-35 |

|

Storage Stability |

month |

6 |

Recommended Ratio

|

|

pbw |

|

DQT-501A blend polyols Isocyanate |

100 100-105 |

Reactivity Characteristics

Component temperature is 20ºC, the actual value is varied according to pipe diameter and processing condition.

|

Cream Time |

3-5s |

|

Gel Time |

6-10s |

Foam Performances

|

items |

Test Method |

Index |

|

Density |

GB 6343 |

120-150 kg/m3 |

|

Closed-cell Rate |

GB 10799 |

≥90% |

|

Initial Thermal Conductivity(15ºC) |

GB 3399 |

≤24mW/(m.K) |

|

Compressive Strength |

GB/T8813 |

≥450kPa |

|

Adhesive Strength |

GB/T16777 |

≥360kPa |

|

Elongation at break |

GB/T9641 |

≥30% |

|

Dimentional Stability 24h -20ºC |

GB/T8811 |

≤1% |

|

24h 70ºC |

|

≤1.5% |

|

Water Absorption |

GB 8810 |

≤3% |

|

Oxygen Index |

GB 8624 |

≥26 |

Another PU--- Wood Imitation Rigid Polyurethane Blend Polyols

hardness, simple molding process, high production efficiency and excellent appearance. Characteristics are as follows, 1.Excellent

repetition molding property. It not only can mould certain shape size, but also mould lifelike wood texture and other designs,

good touch. 2.Appearance and feel close to wood, which could be planed, nailed, drilled, and carved patterns or designs. 3.Mold

can be aluminum or steel, and silicon rubber, epoxy resin or other resins, which are low cost and easy machining. 4.Process is

simple, fast, high efficiency of qualified. 5.Physical and mechanical properties is one of optimal synthesis wood produced by

various polymer. Physical property can be controlled by adjusting the formula.