- Product Details

- {{item.text}}

Quick Details

-

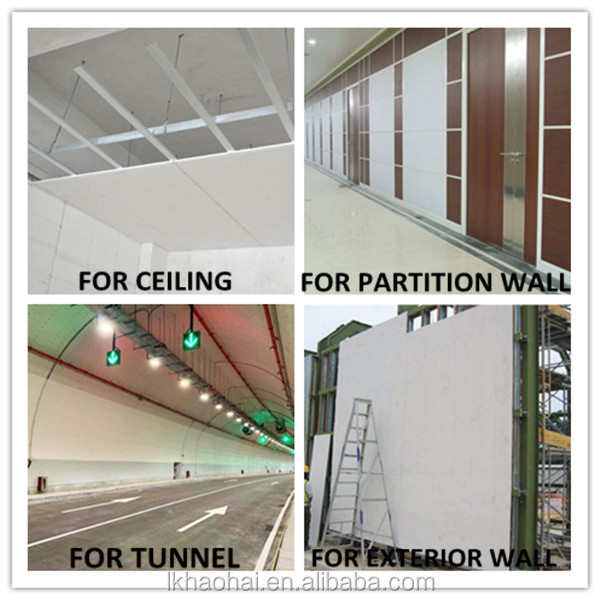

Application:

-

Hotel, Villa, Office Building, Hospital, School, Mall, Sports Venues, Supermarket, Warehouse, Workshop

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Haohai

-

Model Number:

-

JN

-

Name:

-

Calcium silicate board

-

Bulk Density:

-

160-330 (±10%) Kg/m3

-

Flexural Strength:

-

≥0.30Mpa

-

Thermal Cond:

-

≤0.070+0.00011tW/m.k

-

Temp Limit:

-

1050°C

-

Linear Shrinkage:

-

≤1.5% (1000°C,16hrs)

-

Color:

-

White calcium silicate board

-

No-flammable:

-

A1 grade

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Training, Return and Replacement

-

Project Solution Capability:

-

Others

-

Application:

-

Hotel, Villa, Office Building, Hospital, School, Mall, Sports Venues, Supermarket, Warehouse, Workshop

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Haohai

-

Model Number:

-

JN

-

Name:

-

Calcium silicate board

-

Bulk Density:

-

160-330 (±10%) Kg/m3

-

Flexural Strength:

-

≥0.30Mpa

-

Thermal Cond:

-

≤0.070+0.00011tW/m.k

-

Temp Limit:

-

1050°C

-

Linear Shrinkage:

-

≤1.5% (1000°C,16hrs)

-

Color:

-

White calcium silicate board

-

No-flammable:

-

A1 grade

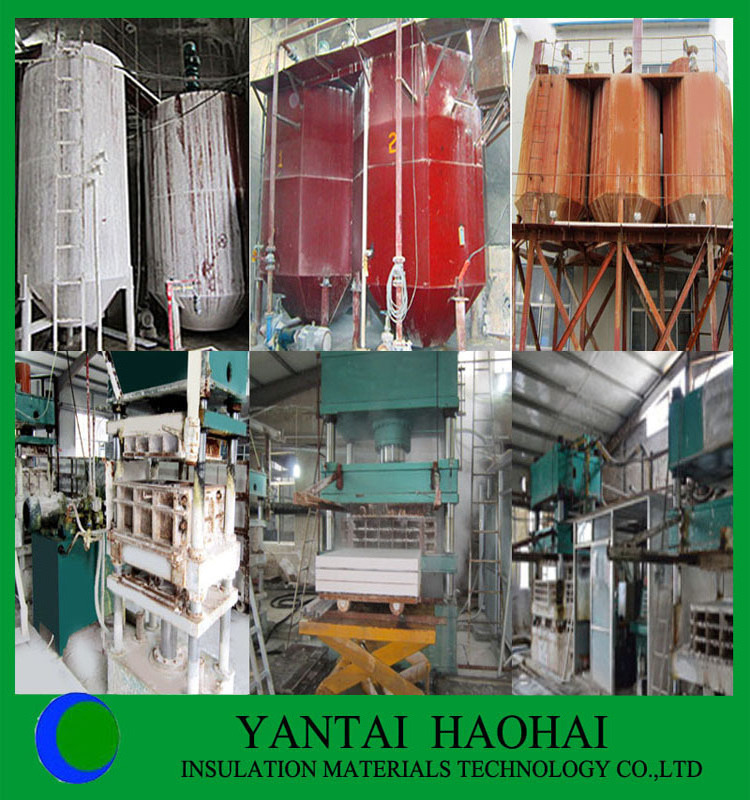

1100 degree high temperature resistant 25mm heat insulation materials fireproof calcium silicate board

1:Good durability, and can withstand high-temperature limit of the continuous thermal load

2:We obtained CE, KR and ISO9001

3:The highest heat resistance temperature is up to 1150 degree centigrade

4:The maximum flexural strength is up to 0.7MPa, all Technical Parameters are the best in China , it is better than other calcium silicate board in the market.

5 Our factory is corporate withYantai power plant, uses the steam to product the board, it is different with other factories to produce with the boiler. The product use the steam, the quality much better than use the boiler. And it is very easy to mass product and reduce the waste, the cost is lower than our factory use boiler.

| JN standard type calcium silicate board | |||||

| Item | Unit | JS-16 | JS-20 | JS-23 | JS-33 |

| Density | Kg/m³ | 160±10% | 200±10% | 230±10% | 330±10% |

| Flexural strength | Mpa | ≥0.3 | ≥0.4 | ≥0.55 | ≥1.5 |

| Temperature limit | ℃ | 1050 | 1050 | 1050 | 1050 |

| Liner Shrinkage | % | ≤1.5 (1000℃,16hrs) | ≤1.5 (1000℃,16hrs) | ≤1.5 (1000℃,16hrs) | ≤1.5 (1000℃,16hrs) |

| Thermal conductivity | W/m.k | ≤0.040+0.00011t | ≤0.048+0.00011t | ≤0.050+0.00011t | ≤0.070+0.00011t |

| JN high temperature type calcium silicate board | |||

| Item | Unit | JS-22 | JS-27 |

| Density | Kg/m³ | ≤220 Kg/m³ | ≤270 Kg/m³ |

| Flexural strength | Mpa | ≥0.5 | ≥0.6 |

| Thermal conductivity | W/m.k | ≤0.048+0.00011t | ≤0.056+0.00011t |

| Temperature limit | ℃ | 1150 | 1150 |

| Liner Shrinkage | % | ≤2(1100℃,12hrs) | ≤2(1100℃,12hrs) |

| High strength calicum silicate board | ||

| Item | Unit | Index value |

| Density | Kg/m³ | 600±10% |

| Flexural strength | Mpa | ≥5 |

| Compressive strength | Mpa | ≥13 |

| Thermal conductivity | W/m.k | ≤0.090+0.00011t |

| Temperature limit | ℃ | 1050 |

| Liner Shrinkage | % | ≤2(1000℃,16hrs) |

| Light weight low thermal conductivity calcium silicate board 130 Kg/m³ | ||

| Item | Unit | JS-13 |

| Density | Kg/m³ | 130±10% |

| Flexural strength | Mpa | ≥0.35 |

| Compressive strength | Mpa | ≥0.5 |

| Thermal conductivity | W/m.k | ≤0.040+0.00011t |

| Temperature limit | ℃ | 1050 |

| Liner Shrinkage | % | ≤2(1000℃,16hrs) |

| High density calcium silicate board | |||

| Item | Unit | JS-33 | JS-90 |

| Density | Kg/m³ | 330±10% | 900±10% |

| Flexural strength | Mpa | ≥5 | ≥5 |

| Thermal conductivity | W/m.k | ≤0.070+0.00011t | ≤0.070+0.00011t |

| Temperature limit | ℃ | 900 | 1100 |

| Liner Shrinkage | % | ≤ 1.5 (850℃,16hrs) | ≤ 1.5 (850℃,16hrs) |

| External wall calcium silicate board | |||||

| Item | Unit |

Index value |

|||

| Density | Kg/m³ | 180±10% | 220±10% | 300±10% | 350±10% |

| Compressive strength | Mpa | ≥1.5 | ≥2.2 | ≥2.8 | ≥3.5 |

| Flexural strength | Mpa | ≥0.9 | ≥1.5 | ≥2.0 | ≥2.5 |

|

Screw pull-out strength |

N/mm | ≥25 | ≥30 | ≥40 | ≥50 |

| High temperature shrinkage | % | ≤ 1.5 (1000℃,3h) | |||

| Thermal conductivity | W/m.k | 0.036 | 0.046 | 0.062 | 0.073 |

| Fire resistant limit | Min | 180 | 180 | 180 | 180 |

| Hydrophobic rate | % | 98 | 98 | 98 | 98 |

| Non-flammable | Grade | A1 Grade in accordance with GB8624-2006 | |||

| Amount of sound insulation | dB | 125 | |||

| Miosture content | % | ≤7.5 | ≤7.5 | ≤7.5 | ≤7.5 |

| Fire rated door core board (calcium silicate board ) | ||||

| Item | Unit | Index value | ||

| Density | Kg/m³ | 180±10% | 220±10% | 270±10% |

| Compressive strength | Mpa | ≥1.5 | ≥2.0 | ≥2.6 |

| Flexural strength | Mpa | ≥0.8 | ≥1.0 | ≥1.5 |

| Screw pull-out strength | N/mm | ≥25 | ≥30 | ≥40 |

|

High temperature shrinkage (1000℃,3h) |

% | ≤ 1.5 | ≤ 1.5 | ≤ 1.5 |

| Thermal conductivity | W/m.k | 0.048 | 0.056 | 0.065 |

| Fire resistant limit | Min | 360 | 360 | 360 |

| Non-flammable |

Grade |

A1 Grade in accordance with GB8624-2006 | ||

| Amount of sound insulation | dB | 125 | ||

| Miosture content | % | ≤7.5 | ||

1).Good durability and can withstand high-temperature limit of the continuous thermal load

2).Low thermal conductivity,in the whole scope of use is unmatched within the adiabatic Performance

3).Light weight,high stength,its strength is rigid insulation products in the highest

4).Durability,long-term use of ceramic fiber felt no similar powder

5).Construction practical,with ordinary tools can be arbitrarily cutting products