- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Nanxiang

-

Product name:

-

Alumina Grinding Ball Alumina Grinding media Ball for Industrial

-

Key word:

-

Alumina Grinding Ball

-

Usage:

-

Grinding

-

Shape:

-

Ball

-

Raw material:

-

Al2O3

-

Size:

-

3-60mm

-

Density:

-

≥3.6g/cm3

-

Mosh:

-

9

-

Water absorption:

-

0.01%

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Jiangxi, China

-

Model Number:

-

NX-CB

-

Brand Name:

-

Nanxiang

-

Product name:

-

Alumina Grinding Ball Alumina Grinding media Ball for Industrial

-

Key word:

-

Alumina Grinding Ball

-

Usage:

-

Grinding

-

Shape:

-

Ball

-

Raw material:

-

Al2O3

-

Size:

-

3-60mm

-

Density:

-

≥3.6g/cm3

-

Mosh:

-

9

-

Water absorption:

-

0.01%

Product Description

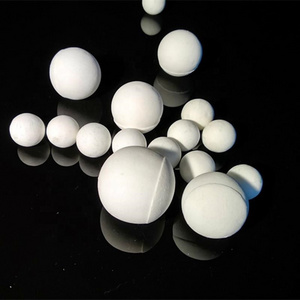

High Density Alumina Grinding Ball Alumina Grinding media Al2O3 Ball for Industrial Ceramic

With small wear loss and high density, alumina grinding media are widely used in the mix and crush procedure of ceramics, glass, glaze and frits, chemical and plastic industries. there are 90%,92% alumina beads.

With overwhelming merits in higher density, more regular shape, easily classifying and assorting,superior grinding efficiency and competitive price prior to natural cobble stones and conventional grinding media,high alumina ceramic grinding balls 6mm 10mm 13mm 20mm for ball milling are excellent for grinding processing of many industries.

Feature

1. High hardness second only to Diamond

2. Lower wear lost

3. Good normalization

4. Good corrosion resistance

5. Higher grinding efficiency

6. Contamination-free

7. Longer service life

1. High hardness second only to Diamond

2. Lower wear lost

3. Good normalization

4. Good corrosion resistance

5. Higher grinding efficiency

6. Contamination-free

7. Longer service life

Advantage

1) High wear-resistance:

The alumina balls wear-resistance is higher than the common alumina balls. When it is working, the ball wont pollute the grinding materials, so it can keep the purity and improve the stability of grinded materials especially the ceramic glaze.

1) High wear-resistance:

The alumina balls wear-resistance is higher than the common alumina balls. When it is working, the ball wont pollute the grinding materials, so it can keep the purity and improve the stability of grinded materials especially the ceramic glaze.

2) High density

The high density, high hardness and the high grinding characters save the grinding time, enlarge the smashing room. So it can improve the grinding efficiency

Application

High alumina ceramic grinding balls 6mm 10mm 13mm 20mm for ball milling are mainly used in precision processing and deep processing of various ceramics, enamels, glasses and thick and hard material in chemical factories, as grinding media for fine grinding machines like ball mills, can-type mills and vibration mills

|

Item

|

High Alumina Ceramic Grinding Ball

|

|

Middle Alumina Ceramic Grinding Ball

|

|

||

|

|

|

|

Micro-Crystal middle alumina

|

Carborundum middle alumina

|

||

|

|

92% Al2O3

|

95% Al2O3

|

65-75% Al2O3

|

60-70% Al2O3

|

||

|

Al2O3(%)

|

92

|

95

|

65-75

|

60-70

|

||

|

SiO2 (%)

|

3.81

|

3

|

20-15

|

60-70

|

||

|

Fe2O3 (%)

|

0.06

|

0.05

|

0.41

|

<0.5

|

||

|

TiO2 (%)

|

0.02

|

0.04

|

1.7

|

1.8

|

||

|

Other (%)

|

2.53

|

1.9

|

5

|

10

|

||

|

Bulk Density (g/cm3)

|

3.65

|

3.68

|

2.93-3.0

|

2.90-3.0

|

||

|

Water Absorption (%)

|

max 0.01

|

max 0.005

|

max 0.01

|

max 0.05

|

||

|

Moh's Hardness (grade)

|

9

|

9

|

min 8

|

min 8

|

||

|

Compressium Strength

|

2000

|

2100

|

1000

|

1000

|

||

|

Abrasion (%)

|

0.01

|

0.0084

|

0.3

|

0.03

|

||

|

Color

|

White

|

White

|

Yellow/White

|

Brown

|

||

|

Raw Material

|

Calcined alumina

|

Calcined alumina

|

Refined bauxite powder

|

Bauxite Powder

|

||

|

Forming Method

|

Isostatic pressing

|

Isostatic pressing

|

Impact Briquetting

|

Handmade

|

||

Details Images

Factory Display

Product Application

Packing & Delivery

|

Package Type

|

Container Load Capacity

|

|

Delivery time

|

Quality

Insurance |

Payment Terms

|

|

|

|

20GP

|

40GP

|

15-20days

|

Chinese National Standard;

Offer quality assurance as request. |

T/T, L/C, Paypal,

West Union |

|

|

Steel drum

|

20-24 tons

|

**

|

|

|

|

|

|

Ton bag

|

20-25 tons

|

**

|

|

|

|

|

|

Plastic bag

|

20-25 tons

|

**

|

|

|

|

|

Hot Searches