- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DAPENG

-

Voltage:

-

220V,380V,415V

-

Power:

-

7.5KW

-

Dimension(L*W*H):

-

3000*2300*1570MM

-

Weight:

-

5000 kg

-

color:

-

as your requirement

-

Cylinders:

-

TWO

-

Columns:

-

four

-

Stroke:

-

50-240mm

-

Cutting area:

-

810*1400mm

-

Cutting force:

-

80tons

-

suitable for material:

-

sponge,foam,plastic,leather,EVA/EPE/PS/HIPS/PET/PP/PE/PU,etc.

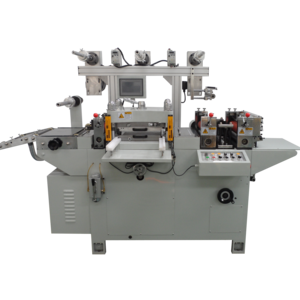

Quick Details

-

Production Capacity:

-

60 pcs/Min

-

Product Type:

-

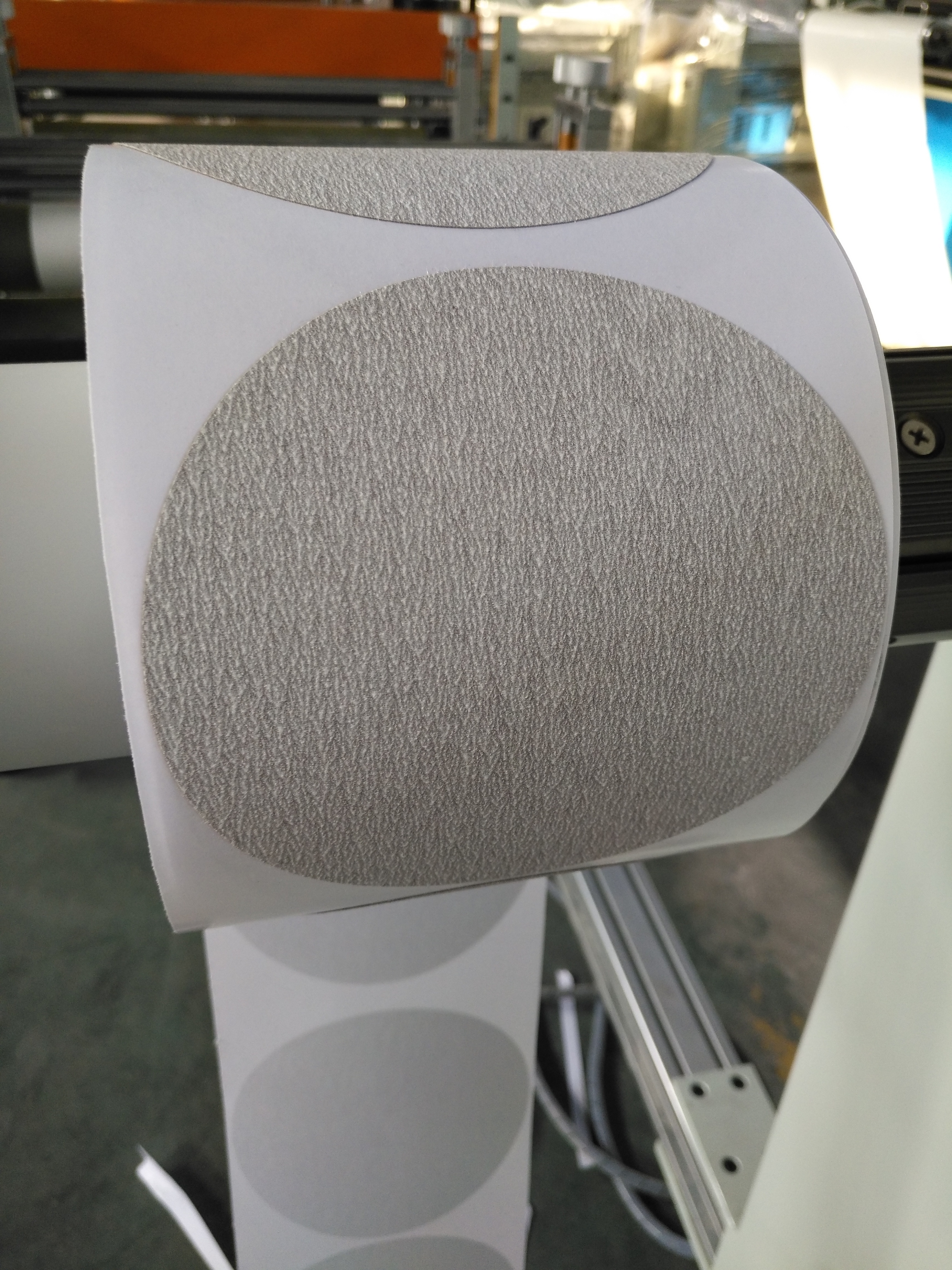

Sanding Discs with Glue Backing making machine

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DAPENG

-

Voltage:

-

220V,380V,415V

-

Power:

-

7.5KW

-

Dimension(L*W*H):

-

3000*2300*1570MM

-

Weight:

-

5000 kg

-

color:

-

as your requirement

-

Cylinders:

-

TWO

-

Columns:

-

four

-

Stroke:

-

50-240mm

-

Cutting area:

-

810*1400mm

-

Cutting force:

-

80tons

-

suitable for material:

-

sponge,foam,plastic,leather,EVA/EPE/PS/HIPS/PET/PP/PE/PU,etc.

Product Description

Specification

|

item

|

value

|

|

Product Type

|

Sanding Discs with Glue Backing making machine

|

|

Processing Type

|

Cutting Machine

|

|

Place of Origin

|

China

|

|

|

Jiangsu

|

|

Brand Name

|

DAPENG

|

|

Voltage

|

220V,380V,415V

|

|

Power

|

7.5KW

|

|

Dimension(L*W*H)

|

3000*2300*1570MM

|

|

Weight

|

5000kg

|

|

Warranty

|

1 Year

|

|

Production Capacity

|

60 pcs/Min

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Marketing Type

|

New Product 2020

|

|

Warranty of core components

|

1.5 years

|

|

Core Components

|

PLC, Motor, Pump

|

|

color

|

as your requirement

|

|

Cylinders

|

TWO

|

|

Columns

|

four

|

|

Stroke

|

50-240mm

|

|

Cutting area

|

450*450mm, 650*600mm, 810*1400mm etc

|

|

Cutting force

|

20tons to 300 Tons

|

|

suitable for material

|

sponge,foam,plastic,leather,EVA/EPE/PS/HIPS/PET/PP/PE/PU,etc.

|

Configuration Data

1. Mitsubishi BRAND PLC

2. Touch Screen

3. Optoelectronic safety

4. Automatic Pressure regulating motor

5. Host Machine Motor

6. Oil Bump

7. Magnetic Valve ,cooler

8. Host Machine hydro-cylinder

9. Flatbed cylinder

10. Servo Motor

Standard functions2 set* material feeding / 1 roll unwinding

* kiss cutting at register

* scrap rewinding

*slitting to 2 rolls

*rewinding on TWO roll at 1 inch air shaft

Details description of machine :

I , unwinding part ---------------max width 450mm

1, unwind : 3 inch air-shaft , AC Motor , frequency control

2, unwinding effective width : 450mm , max diameter is 500mm3, touch sensor sense have material or not4, Servo motor control the

pulling roller , another servo motor at the hydraulic driving systempulling roller is rubber material , opening height is

adjustable at least 24mmII , Main Machine ------------ Die cutting area 450mm*450mm

1, Four shaft hydraulic machine

2, max cutting force : 40 Ton

3, shock proof

4, with light for the die cutting part so that easy installing mould and watch the die cutting part

5, plane die cutting area 450mm length , 450mm width

6, Safety Light Curtains at four corner .

III, electronic PLC control

1, LCD touch screen , computer control base

2, with password for data protection

3, can save the datas that setted

4, low maintainance

5, all the parts are under CE safety standard , electronic parts have CE mark

6, all the cutting / unwinding length and number are can set in the touch screen

7, cutting depth precision control at 0.025mm

8, stroke is controlled in 50--101.6mm

IV ,die cutting mould installing

with clamp tool and locking tool so that can put mould in directly and then locked , change mould in few time

V, mould plate package

1,with up and down cutting boards

2, stainless steel material mould plate , polished , easy control the cutting depth , can cutting both kiss cut and through cut

3, one piece PET or PVC sample for mould protective

VI, scrap/ waste Rewinding

1, three inch airshaft rewinding width AC motor control

2, max rewinding diameter is 500mm,

3, bearing weight at 22KGS

4, effective width 450mm

5, with dancer for the tension control

VII , slitter

1, with one slit knife installed before rewinding

VIII , Rewinder -----------up and down 2 air-shaft for rewind1, with max roll diameter 450mm

2, Rewinding shaft is 3 inch airshaft3, AC motor , speed can increase or descrease , with switch if forward/ reverse4, effective

width have to can rewinding the slitting to 2 p

I , unwinding part ---------------max width 450mm

1, unwind : 3 inch air-shaft , AC Motor , frequency control

2, unwinding effective width : 450mm , max diameter is 500mm3, touch sensor sense have material or not4, Servo motor control the

pulling roller , another servo motor at the hydraulic driving systempulling roller is rubber material , opening height is

adjustable at least 24mmII , Main Machine ------------ Die cutting area 450mm*450mm

1, Four shaft hydraulic machine

2, max cutting force : 40 Ton

3, shock proof

4, with light for the die cutting part so that easy installing mould and watch the die cutting part

5, plane die cutting area 450mm length , 450mm width

6, Safety Light Curtains at four corner .

III, electronic PLC control

1, LCD touch screen , computer control base

2, with password for data protection

3, can save the datas that setted

4, low maintainance

5, all the parts are under CE safety standard , electronic parts have CE mark

6, all the cutting / unwinding length and number are can set in the touch screen

7, cutting depth precision control at 0.025mm

8, stroke is controlled in 50--101.6mm

IV ,die cutting mould installing

with clamp tool and locking tool so that can put mould in directly and then locked , change mould in few time

V, mould plate package

1,with up and down cutting boards

2, stainless steel material mould plate , polished , easy control the cutting depth , can cutting both kiss cut and through cut

3, one piece PET or PVC sample for mould protective

VI, scrap/ waste Rewinding

1, three inch airshaft rewinding width AC motor control

2, max rewinding diameter is 500mm,

3, bearing weight at 22KGS

4, effective width 450mm

5, with dancer for the tension control

VII , slitter

1, with one slit knife installed before rewinding

VIII , Rewinder -----------up and down 2 air-shaft for rewind1, with max roll diameter 450mm

2, Rewinding shaft is 3 inch airshaft3, AC motor , speed can increase or descrease , with switch if forward/ reverse4, effective

width have to can rewinding the slitting to 2 p

Hot Searches