Can be assembled into all kinds of styles houses and buildings, widely used in civil houses and public buildings, such as villas, residential, office buildings, collective dormitory,farm houses, hotels, shops and so on.

- Product Details

- {{item.text}}

Quick Details

-

Features:

-

durable, easy operation

-

Production Capacity:

-

2 modular house per day

-

Dimension(L*W*H):

-

3*6m, 3.3*6.6m, 3.6*7.2m

-

Power:

-

41KW for the whole production line

-

Voltage:

-

380V

-

Weight (KG):

-

20000

-

Product name:

-

Prefab Concrete Modular House

-

Suitable for:

-

Small building project

-

Application Site:

-

House/Hotel/ Restaurant/Villa Construction

-

Advantage:

-

low cost, quick build, anti-earthquake, insulation

-

After-sales Service:

-

offer engineer to install and training for 30 days at least

-

Raw materials:

-

Reinforced concrete

-

Needed machine 1:

-

Forming Machine,Quick-solidifying Machine, CNC Rebar Machine

-

Needed machine 2:

-

Concrete Mixer, Batching Machine, Assembled Storage Tank

Quick Details

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

HBTC

-

Application:

-

hotel, school, villa, restaurant

-

Features:

-

durable, easy operation

-

Production Capacity:

-

2 modular house per day

-

Dimension(L*W*H):

-

3*6m, 3.3*6.6m, 3.6*7.2m

-

Power:

-

41KW for the whole production line

-

Voltage:

-

380V

-

Weight (KG):

-

20000

-

Product name:

-

Prefab Concrete Modular House

-

Suitable for:

-

Small building project

-

Application Site:

-

House/Hotel/ Restaurant/Villa Construction

-

Advantage:

-

low cost, quick build, anti-earthquake, insulation

-

After-sales Service:

-

offer engineer to install and training for 30 days at least

-

Raw materials:

-

Reinforced concrete

-

Needed machine 1:

-

Forming Machine,Quick-solidifying Machine, CNC Rebar Machine

-

Needed machine 2:

-

Concrete Mixer, Batching Machine, Assembled Storage Tank

Product Description

Concrete Modular House

It is also called precast concrete house,belonging to concrete assembly building.It is a new type of construction method with good energy saving and low construction cost. It adopts reinforced concrete structure, which is prefabricated into unit modules in the factory through special equipment, and then directly transported to the site for assembly. The level of prefabrication is high, the size is accurate, the construction speed is very fast, and 500 square meters can be built in one day, which greatly increases the construction speed

It realized the industrial production of concrete houses. It can be used to build permanent building or as relocation house. It is characterized by earthquake resistant and wind resistant, moisture proof and fireproof , sound insulation and heat insulation. Can be assembled into all kinds of styles houses and buildings, widely used in civil houses and public buildings, such as villas, residential, office buildings, collective dormitory,farm houses, hotels, shops and so on.

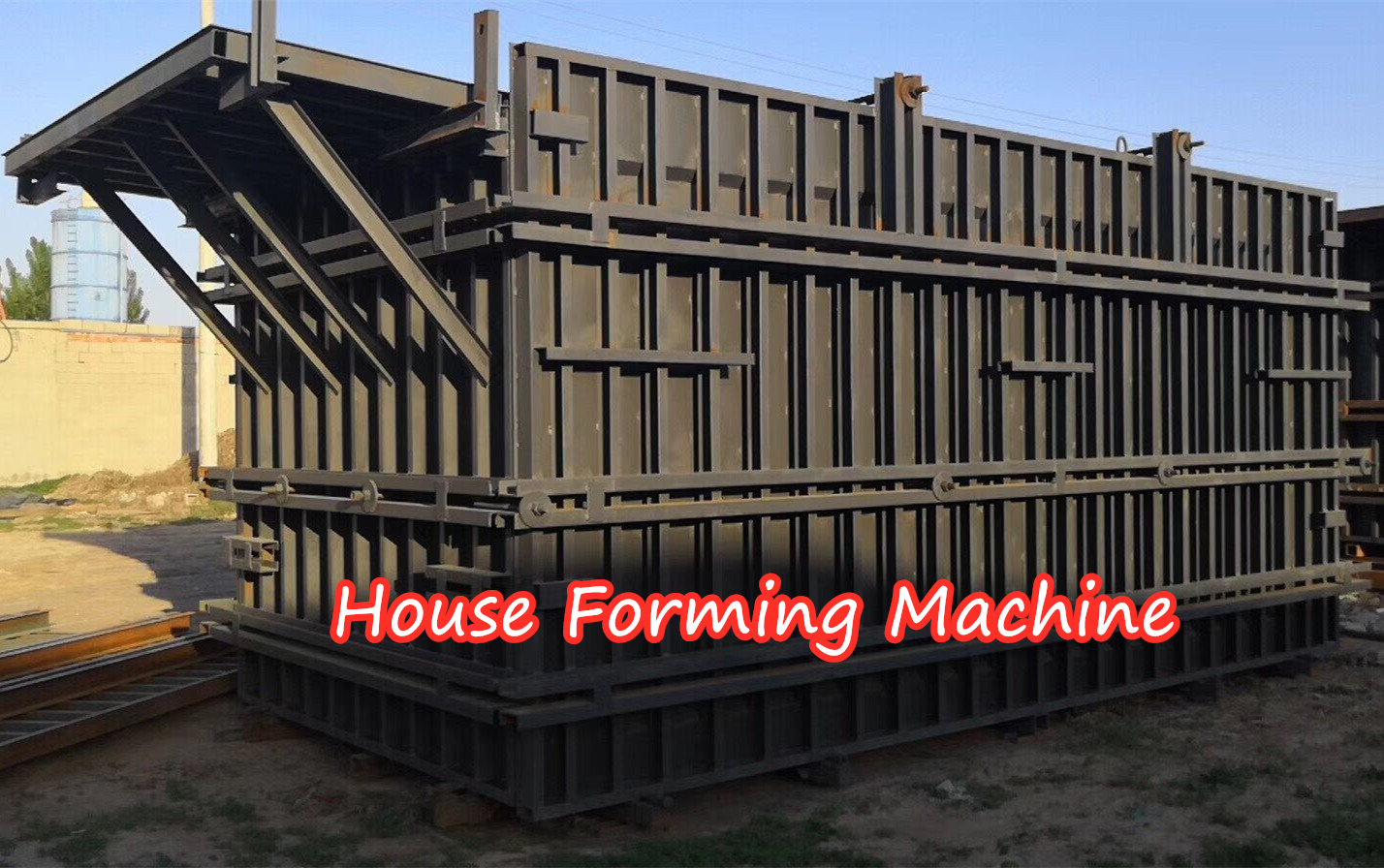

We use below machine line to manufacture the each unit concrete modular house.

Please check below machine pictures.

1. House Forming Machine

2. Concrete Mixer

3. CNC Rebar Machine

4. Quick-solidifying Machine

5. Assembled Storage Tank

6. Batching Machine

How To Produce The Concrete Modular House?

1.Processing the rebar by

CNC rebar Machin

e ,and weave the rebar(reinforcement)into grid and cover it on the inner chassis of

forming machine.

2.Producing the concrete by the

concrete machines

.

3.Adjust the

forming machine

, and use the gantry crane and hopper to hoist the concrete and pour into the machine until it is full .

4.Cover the forming machine with the cover of

quick-solidifying machine

,and

then turn on quick-solidifying machine to make the concrete solidify quickly .

5.After 2-3 hours, a unit modular house is finished, pull open the side sheet of forming machine, adjust inner chassis shrink to detach the wall of house. Use the gantry crane hoist the house and store it.

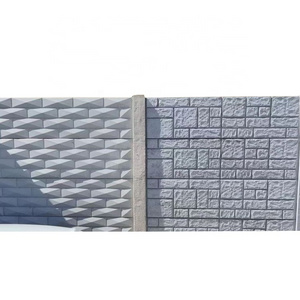

Finished Products Description

Advantage and Application

1. Low cost: The construction cost of this house is only half of traditional brick and concrete house.

2. Extreme speed of construction: High level of prefabrication, fast construction speed, 500 square meters per day, greatly improving construction speed.

3. Earthquake resistance: It can withstand a magnitude 9 earthquake and will not collapse as a whole due to local damage during earthquake.

4. Wind-resistant: It can withstand a hurricane of 200km/h. The weight of each unit module is 20 tons (the weight of 10 cars).

5. Durable: Lifetime of main structure with reinforced concrete can reach more than 100 years.

6. Fire retardant: Reinforced concrete structure solid wall, fire resistance time is long.

7. Sound insulation: The amount of sound insulation of the wall can reach more than 65dB.

8. Insulation: Reinforced concrete structure solid wall, good thermal insulation

9. Energy-saving and environmental protection: new green buildings, it doesn’t produce construction rubbish during construction, and can be removed again during demolition and reuse.

10. Flexible assembly: It can be assembled into all kinds of styles houses and buildings, each room can be assembled by one or more units modules, up to five floors.

Building Project Cases

Hot Searches