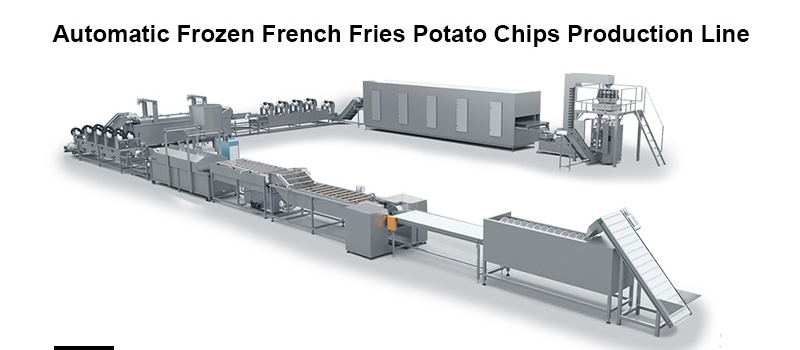

This is a large output production line to produce good quality frozen French fries. It has the advantages of high automation, simple operation and energy-saving.

Frozen French fries can be kept longer than potato chips that are the reason why some noshery and restaurant cook French fries to sell. This FFrench fries plant can process high quality frozen French fries that comply with health standards.