- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Industrial Process Water

-

Type:

-

Pure Water Treatment System

-

Capacity:

-

< 1000 m3/h

-

Resin:

-

Anionic / Cationic / Mixed Bed

Quick Details

-

Place of Origin:

-

Istanbul, Turkey

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Free spare parts, Online support

-

Product name:

-

Demineralization / Deionization Water System

-

Application:

-

Industrial Process Water

-

Type:

-

Pure Water Treatment System

-

Capacity:

-

< 1000 m3/h

-

Resin:

-

Anionic / Cationic / Mixed Bed

Ion Exchange Resins (by DUPONT)

Ion exchange (IX) resins are polymers that are capable of exchanging ions with ions in a solution that is passed through them.

Our world-class IX resins serve applications as diverse as industrial water softening, pharmaceutical formulations, sweetener purification, mining and more. Our IX resins come in a variety of chemical compositions, polymer structures, and particle sizes to meet current and developing industry needs and requirements.

To help decide which IX product is best for you, check out our handy periodic table on the right.

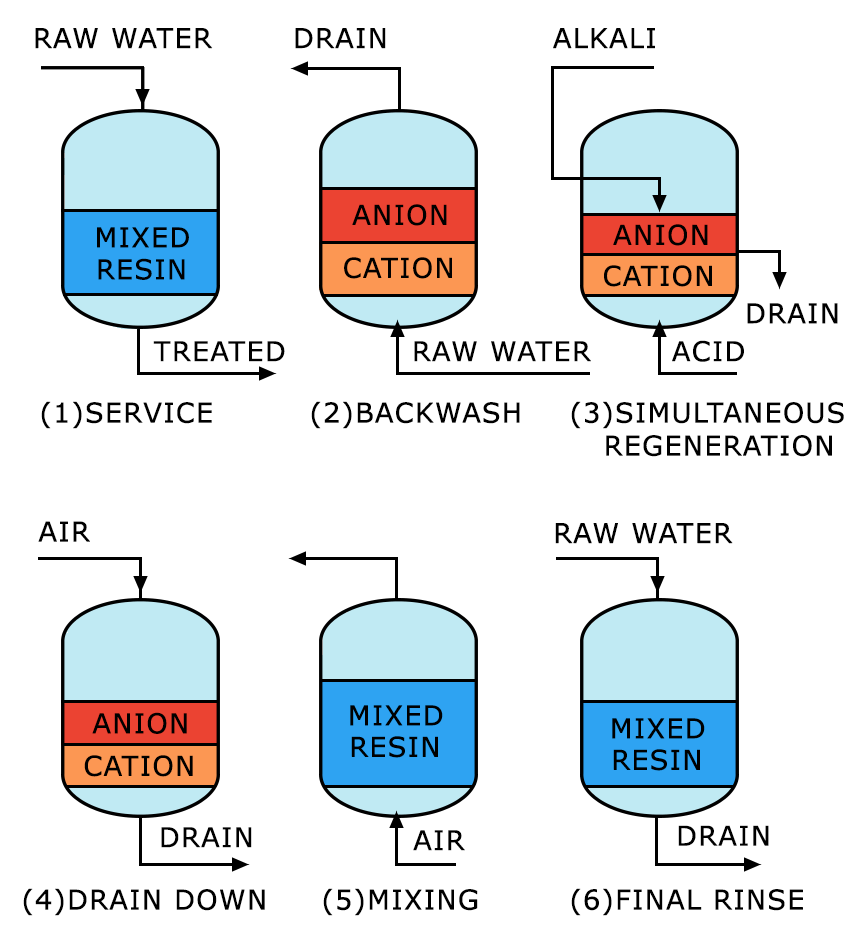

In ion exchange, ions present in the water bind to a solid material (resin, adsorbent) by means of adsorption. The ions to be removed from the water can be exchanged with ions present on the resin (e.g. softening by exchanging calcium for sodium ions), or can be removed entirely by the resin without any exchange (e.g. for the production of demineralised water). There are many resins available on the market, each of which has its own specific properties. If the ion exchanger is saturated with exchanged/removed ions, the ions are removed from it using a regenerating agent, which is usually an acid or base.

Ion exchangers can be divided into cation and anion exchangers. Cation exchangers bind positive ions and anion exchangers bind negative ions. Mixed bed systems containing both cation and anion resins are also used.

Ion exchanger

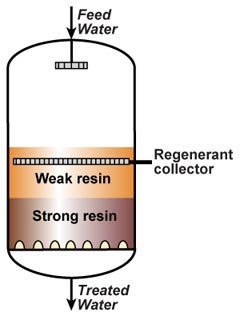

Chambers (filter tanks) which can be filled with granulated resin are used for ion exchange. The chambers are equipped with strainers at the top and bottom to prevent the resin from washing out. The exact design of the ion exchanger depends on the application: single-bed ion exchanger (cation or anion resin) or double-bed (mixed bed with cation and anion resin / strong and weak). An ion exchanger is also equipped with a regeneration station (salt, acid and/or base).

The chambers of the ion exchangers are available in plastic, steel and coated steel. Plastic can be used up to around 5 to 10 m³/h and steel is usually used for ion exchangers intended for higher flow rates.

There are numerous resins available on the market, all of which have their own specific properties. We will be happy to find the best resin for your purposes and the best setup for your installation.

ENGINEERING, DESIGN & SERVICE of CONSULTANCY

AAT’s engineering expertise includes traditional disciplines, architectural, civil, electrical, mechanical, piping, and structural engineering; as well as advanced specialties, including simulation, enterprise integration, integrated automation processes, and interactive 3D modeling. Many of AAT’s engineers are technical experts in their areas.

AAT integrates engineering, procurement, fabrication , construction, maintenance, and project management. The project design process incorporates early involvement of construction and commissioning expertise, to ensure projects are designed to be constructed and operated in the most efficient manner.