- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Drills-King or OEM

-

Model Number:

-

DKSB9980

-

Product name:

-

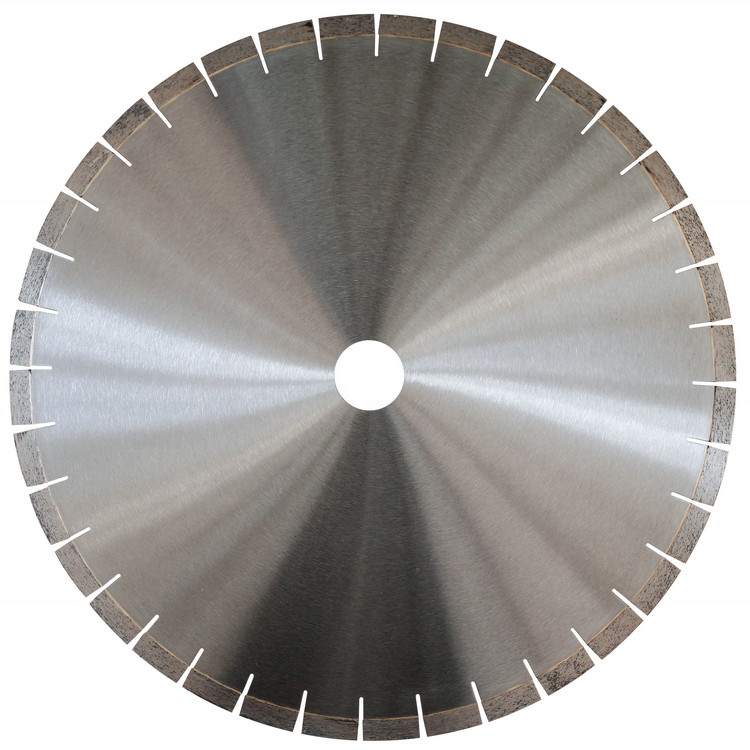

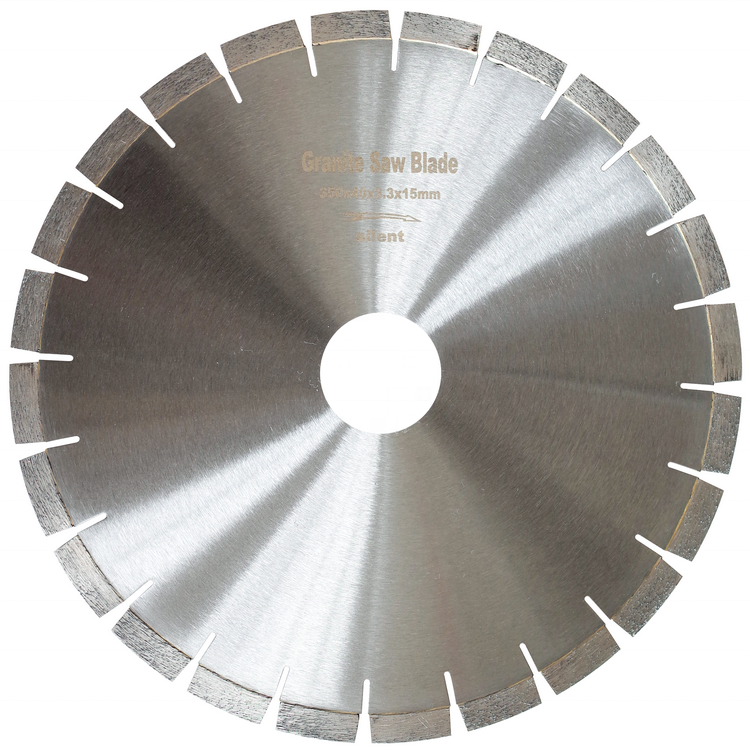

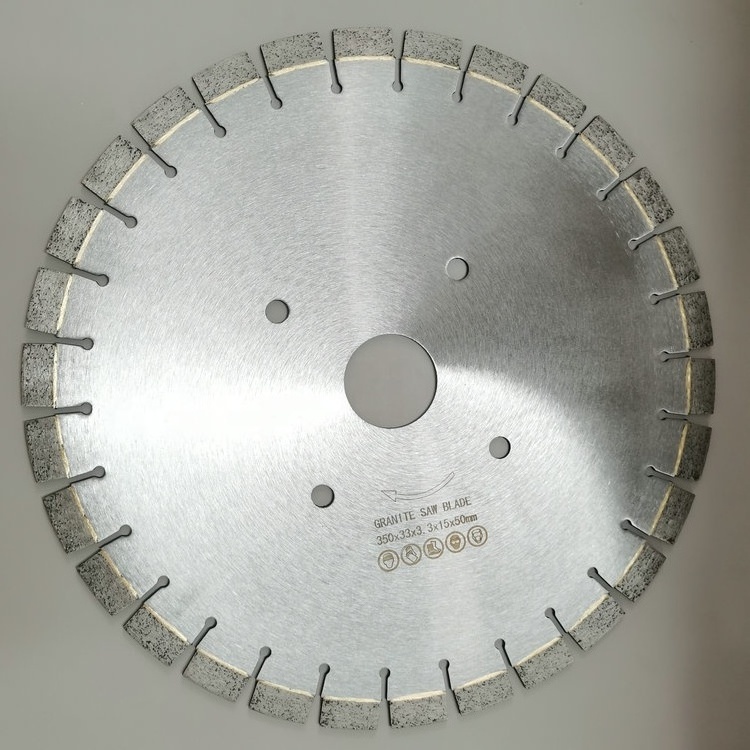

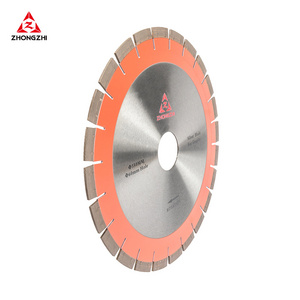

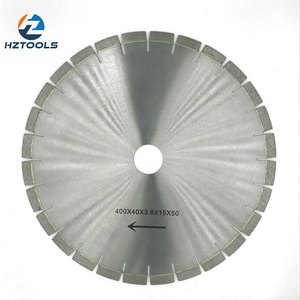

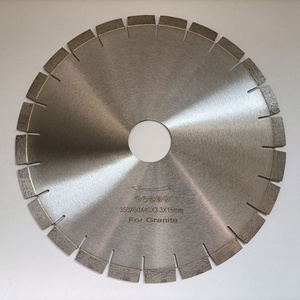

silent core bridge saw diamond saw blade for granite

-

Application:

-

cutting hard stone,such as granite and sandtone

-

Blade material:

-

Alloy Steel

-

Cutting machinery:

-

hand manual angle grinder

-

Diamond blade type:

-

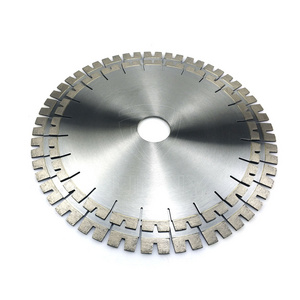

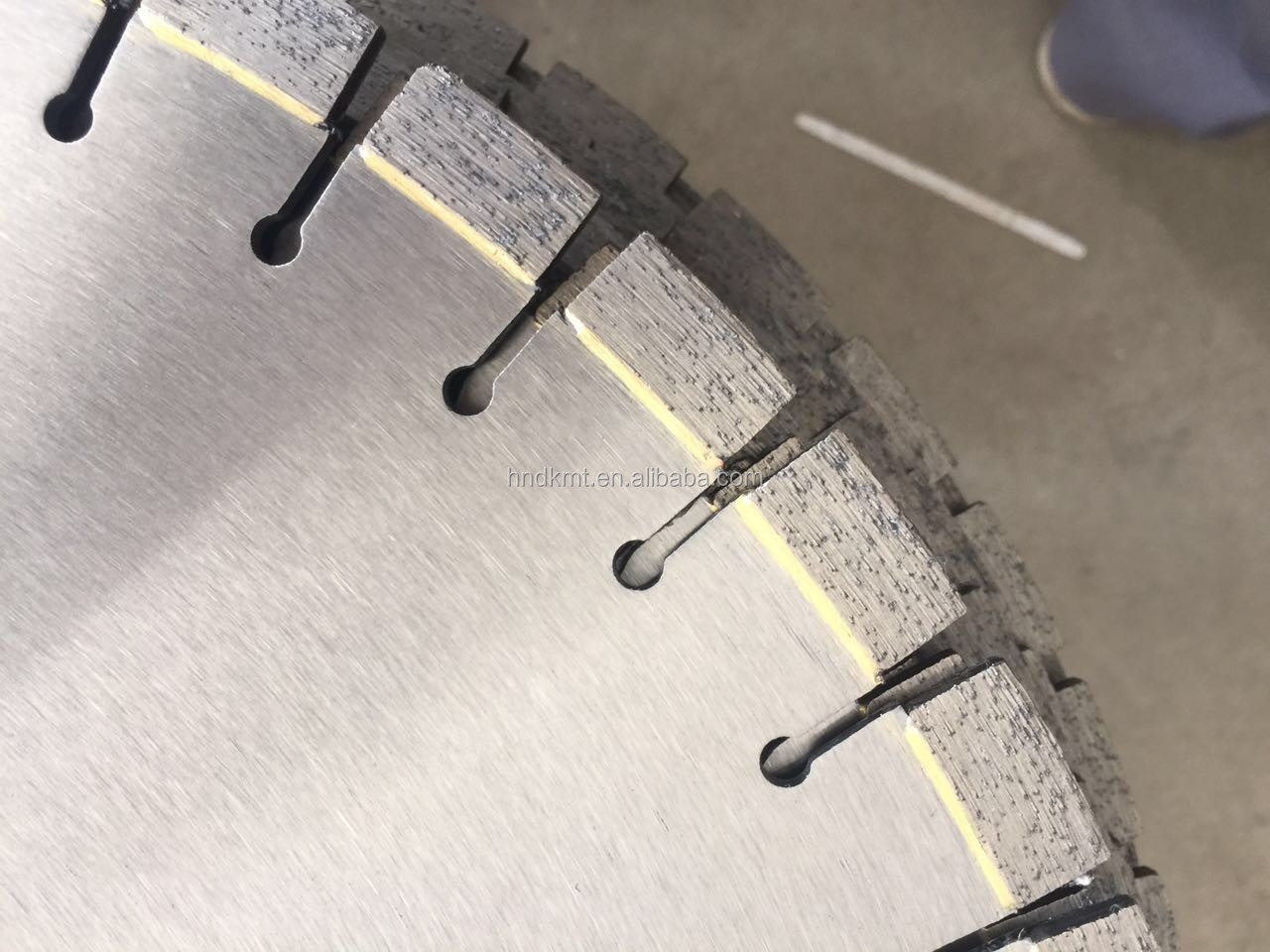

turbo segmented with protectsegment

-

Hot/cold processing:

-

durable high speed cutting saw blade

-

Saw blade diameter:

-

105mm-400mm, 4''-16''

-

Inner hole size:

-

22.23mm or as per require

-

Manufacturing processing:

-

hot pressing sintering

-

Certification:

-

ISO9001:2008

Quick Details

-

Blade Length:

-

6in

-

Finishing:

-

diamond

-

Size:

-

105mm-400mm, 4''-16''

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Drills-King or OEM

-

Model Number:

-

DKSB9980

-

Product name:

-

silent core bridge saw diamond saw blade for granite

-

Application:

-

cutting hard stone,such as granite and sandtone

-

Blade material:

-

Alloy Steel

-

Cutting machinery:

-

hand manual angle grinder

-

Diamond blade type:

-

turbo segmented with protectsegment

-

Hot/cold processing:

-

durable high speed cutting saw blade

-

Saw blade diameter:

-

105mm-400mm, 4''-16''

-

Inner hole size:

-

22.23mm or as per require

-

Manufacturing processing:

-

hot pressing sintering

-

Certification:

-

ISO9001:2008

1.hot press , cold press , dry cutting, wet cutting, dry and wet cutting

2. long working lifetime , precise cutting effect

3. The diamond blades are disigned for cutting Floor Tiles,Quarry Tiles, Marble Tiles, Granite, Marble, Terrazzo, Slate, Nature stone,General build materials.

Advantages of 600mm diamond concrete saw blade :

1. Smooth&fast cutting without chipping

2. Long life span and stable performance

3. Competitive price and superior quality

4. Safe package and fast delivery

5. Professional&excellent service

13 Kinds of Laser Welded Diamond Saw Blade as follow:

1st GENERAL PURPOSE(KEY SLOT)

2nd ASPHALT/GREEN CONCRETE(DEEP SEGMENT)

3rd ASPHALT/GREEN CONCRETE(TCT INSERTED)

4th ASPHALT/GREEN CONCRETE(DROP SEGMENT)

5th ASPHALT/GREEN CONCRETE(DEEP-DROP SEGMENT)

6th CURED CONCRETE(SHORT SEGMENT)

7th CURED CONCRETE/GRANITE(TURBO SEGMENT)

8th CURED CONCRETE/GRANITE(W-SHAPE SEGMENT)

9th CURED CONCRETE/GRANITE(S-SHAPE SEGMENT)

10th CURED CONCRETE/ASPHALT(DROP SLOT)

11th CURED CONCRETE/ASPHALT(WIDE SKEW U SLOT)

12th CURED CONCRETE/ASPHALT(MIXED SEGMENT)

13th GRANITE/MARBLE(NARROW U SLOT)

Laser welding technology enables the manufacturing process to be highly automated,resulting in greatly improved stability and stronger adhesion of the diamonds to the metal substrate.The result is improved efficiency ,cutting life and operator safety.

Application of General Purpose Laser Welded Blade: Designed for high performance -cutting of an extensive range of masonry marble ,asphalt ,granite and concrete material including bricks, blocks,slate,stone,etc.

Diamond blade also called diamond cutting disc, is a diamond saw blade which has diamond segments on its edge for cutting hard or abrasive materials. There are many types of diamond blade, and circular diamond saw blades are the most widely used type of diamond blade. The applications including marble, granite, concrete, asphalt, masonry, bricks, glass, and ceramics in the construction industry. General purpose blades are also available.The manufacturing methods of diamond blades including sintering, vacuum brazing and electroplating.

Segmented turbo diamond cutting disc for porcelain tiles with smooth cutting

Mini diamond cutting blade with flange 5/8"-11 for granite stones

Laser welded diamond saw blade for ceramic tiles with safe cutting

Shipping

1. TNT/FedEx/DHL/UPS for samples or under 45KG wegight goods , Door to Door.

2. By Air or by Sea for batch goods,from airport(seaport) to airport(seaport).

3. Customers specifying freight forwarders or not.

4. Production Time: 3- 7days for samples; 2-3.5 weeks for batch goods.

We have a bond designed to optimize your saw's cutting performance when cutting marble or other soft stone, such as travertine and limestone. Marble cutting blades provide efficient cutting in soft materials, as well as providing a smooth cut. The fact that a marble blade leaves a better working area is key to finishing the job in less steps. Drills-King Marble Blades allow you to do this by providing a chip free edge and consistent cut of marble and soft stone. Remember the surface feet per minute should be faster when cutting marble. Adjust your saw's RPM or you can compensate by using a larger size marble blade than granite. Example: if RPM is set for using 14" granite blade, leave saw at that RPM, but use a 16" marble blade.