Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Hardness:

-

50-90 Shore

-

Feature:

-

Oil/Chemical/High Temperature/Waterproof/Wear Resistant

-

Color:

-

Black/Brown/Green/Yellow/Blue/Clear/Red etc.

-

Temperature:

-

-20℃ -+ 260℃

-

OEM:

-

Accept

-

Certificate:

-

ISO9001

-

year established:

-

2009

Quick Details

-

Place of Origin:

-

Fujian, China, FUJIAN, China

-

Material:

-

NBR/FKM/HNBR/FFKM/EPDM/Silicone etc.

-

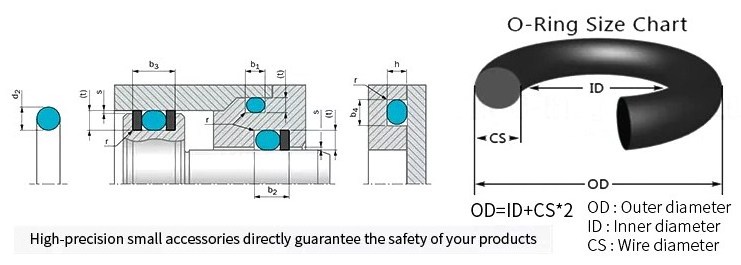

Size:

-

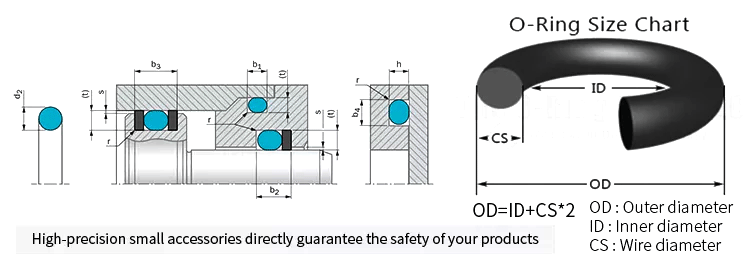

Rubber O Ring Seals, ID*C/S(mm)

-

Hardness:

-

50-90 Shore

-

Feature:

-

Oil/Chemical/High Temperature/Waterproof/Wear Resistant

-

Color:

-

Black/Brown/Green/Yellow/Blue/Clear/Red etc.

-

Temperature:

-

-20℃ -+ 260℃

-

OEM:

-

Accept

-

Certificate:

-

ISO9001

-

year established:

-

2009

O-Rings are available in the following elastomers:

Aflas? or Kalrez?(FFKM) Acrylate Rubber(ACM) Butyl Rubber(IIR) Ethylene-propylene (EPR, EPDM) Ethylene Acrylate Rubber(AEM) Fluorocarbon (FKM/FPM) Fluorosilicone(FVMQ) Hydrogenated Nitrile (HNBR) Liquid Silicone Rubber(LSR) Neoprene Rubber(CR) Nitrile Rubber (Buna-N/NBR) Natural Rubber(NR) Polyurethane(PU) Silicone Rubber Styrene-butadiene Rubber (SBR)

♦ If you need a special compound for the O-Ring, we can develop one for you.

Aflas? or Kalrez?(FFKM) Acrylate Rubber(ACM) Butyl Rubber(IIR) Ethylene-propylene (EPR, EPDM) Ethylene Acrylate Rubber(AEM) Fluorocarbon (FKM/FPM) Fluorosilicone(FVMQ) Hydrogenated Nitrile (HNBR) Liquid Silicone Rubber(LSR) Neoprene Rubber(CR) Nitrile Rubber (Buna-N/NBR) Natural Rubber(NR) Polyurethane(PU) Silicone Rubber Styrene-butadiene Rubber (SBR)

♦ If you need a special compound for the O-Ring, we can develop one for you.

♦

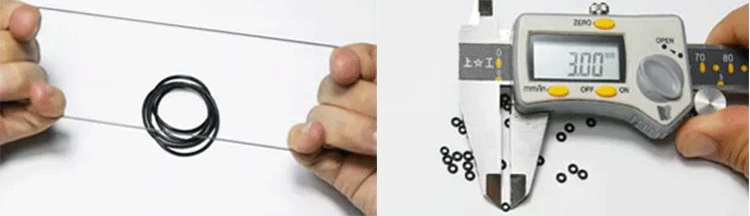

Strong Stretchability

we can produce sealed products with good stretch-ability to meet customer specials FPR stretch

♦ High Precision

we strictly control every production detail and ensure product accuracy

♦ High-quality Products

the product suirace is smooth ,with no flash and flaws

♦ Variety of Materials

Smooth and textured surface, no burrs

we can produce sealed products with good stretch-ability to meet customer specials FPR stretch

♦ High Precision

we strictly control every production detail and ensure product accuracy

♦ High-quality Products

the product suirace is smooth ,with no flash and flaws

♦ Variety of Materials

Smooth and textured surface, no burrs

|

Model number

|

NBR,EPDM,SILICONE,FKM,SBR,NR,etc.

|

|

Hardness Range

|

20-90 Shore A

|

|

Color

|

Any color can be customized

|

|

Size

|

AS568, PG & Non-Standard O-Rings

|

|

Tolerance Standard

|

AS568, ISO2768-M or ISO3302-1:2014 CLASS M2

|

|

Application

|

For all industries

|

|

Factory Establishment Time

|

Year 2009

|

|

Service

|

ODM/OEM

|

|

Certificate

|

ISO9001,RoHS,REACH

|

|

Factory location

|

Ningde City, Fujian Province, China

|

Product Features

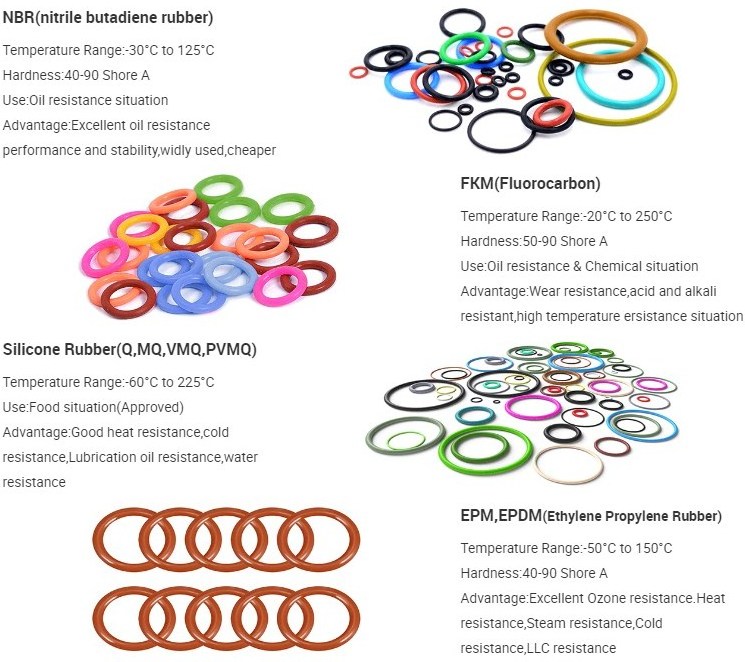

NBR(nitrile butadiene rubber)

Temperature Range:-30°C to 125°C

Hardness:40-90 Shore A

Use:Oil resistance situation

Advantage:Excellent oil resistance performance and stability,widly used,cheaper

FKM(Fluorocarbon)

Temperature Range:-20°C to 250°C

Hardness:50-90 Shore A

Use:Oil resistance & Chemical situation

Advantage:Wear resistance,acid and alkali resistant,high temperature ersistance situation

Silicone Rubber(Q,MQ,VMQ,PVMQ)

Temperature Range:-60°C to 225°C

Use:Food situation(Approved)

Advantage:Good heat resistance,cold resistance,Lubrication oil resistance,water resistance

EPM,EPDM

(Ethylene Propylene Rubber)

Temperature Range:-50°C to 150°C

Hardness:40-90 Shore A

Advantage:Excellent Ozone resistance.Heat resistance,Steam resistance,Cold resistance,LLC resistance

HNBR(Hydrogenated Nitrile Butadiene)

Temperature Range:-30°C to 160°C

Hardness:50-90 Shore A

Advantage:Excellent Ozone resistance.Heat resistance,Mechanical strength,Ozone resistance better than NBR

CR(Neoprene Rubber)

Temperature Range:-44°C to 120°C

Hardness:60-90 Shore A

Advantage:Excellent mechanical strength and Fatigue resistance

Technical Information

Why Choose Us

♦

Quick Response

♦Professional Team

R&D engineers and process engineers with more than 30 years of professional technical service can answer customers' design questions at any time. Realize seamless connection between product design and product application

R&D engineers and process engineers with more than 30 years of professional technical service can answer customers' design questions at any time. Realize seamless connection between product design and product application

♦

Support Customization

Support all kinds of rubber and plastic products related customization, if all of our products cannot meet your requests, we also can specially customize the products for you as per your samples,drawings, etc.

Support all kinds of rubber and plastic products related customization, if all of our products cannot meet your requests, we also can specially customize the products for you as per your samples,drawings, etc.

♦

JTSST Database

In 13 years,we have delivered more than 800,000,000 products to customers, and they are still functioning in nearly 100 million equipment types. Over 20,000 elastomer formulations and injection molding processes are readily available in our database. In the field of flow control, we can provide more than 330 kinds of check valve samples for customers to test.

In 13 years,we have delivered more than 800,000,000 products to customers, and they are still functioning in nearly 100 million equipment types. Over 20,000 elastomer formulations and injection molding processes are readily available in our database. In the field of flow control, we can provide more than 330 kinds of check valve samples for customers to test.

♦Q

uality Control

Our products are highly consistent with the requirements of the ISO international quality management system, and internal laboratory tests are used in product testing to advance synchronously with third-party organizations such as SGS and China Testing.

Our products are highly consistent with the requirements of the ISO international quality management system, and internal laboratory tests are used in product testing to advance synchronously with third-party organizations such as SGS and China Testing.

Certificate

we have obtainved

ISO9001:2015、REACH、RoHS、SGS-PAHS、TSCA、SGS-Ozone aging、SGS-Phthalate、SGS-UV aging SGS-POPs

、

Diaphragm valve patent、

Pressure relief valve patent

and other certifications for different market requirements

Category

Hot Searches