- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

6517, 6014, 6515

-

Shape:

-

Lump, Briquette

-

Material:

-

SiMn Alloy

-

Chemical Composition:

-

Mn, Si, Fe, P, S

-

Product name:

-

Silicon Manganese

-

Color:

-

Gray

-

Size:

-

0-3MM, 1-10MM, 10-100MM, Or As Customer Required

-

Standard:

-

National Standard

-

Packing:

-

In 1MT Jumbo Bag Or As Your Requirement

-

Usage:

-

Widely

-

Feature:

-

Lower Prices

-

PAYMENT TERM:

-

T/T

-

Quality:

-

High-quality

-

MOQ:

-

20 Metric Ton

Quick Details

-

Application:

-

Steel Making

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Kongfang

-

Model Number:

-

6517, 6014, 6515

-

Shape:

-

Lump, Briquette

-

Material:

-

SiMn Alloy

-

Chemical Composition:

-

Mn, Si, Fe, P, S

-

Product name:

-

Silicon Manganese

-

Color:

-

Gray

-

Size:

-

0-3MM, 1-10MM, 10-100MM, Or As Customer Required

-

Standard:

-

National Standard

-

Packing:

-

In 1MT Jumbo Bag Or As Your Requirement

-

Usage:

-

Widely

-

Feature:

-

Lower Prices

-

PAYMENT TERM:

-

T/T

-

Quality:

-

High-quality

-

MOQ:

-

20 Metric Ton

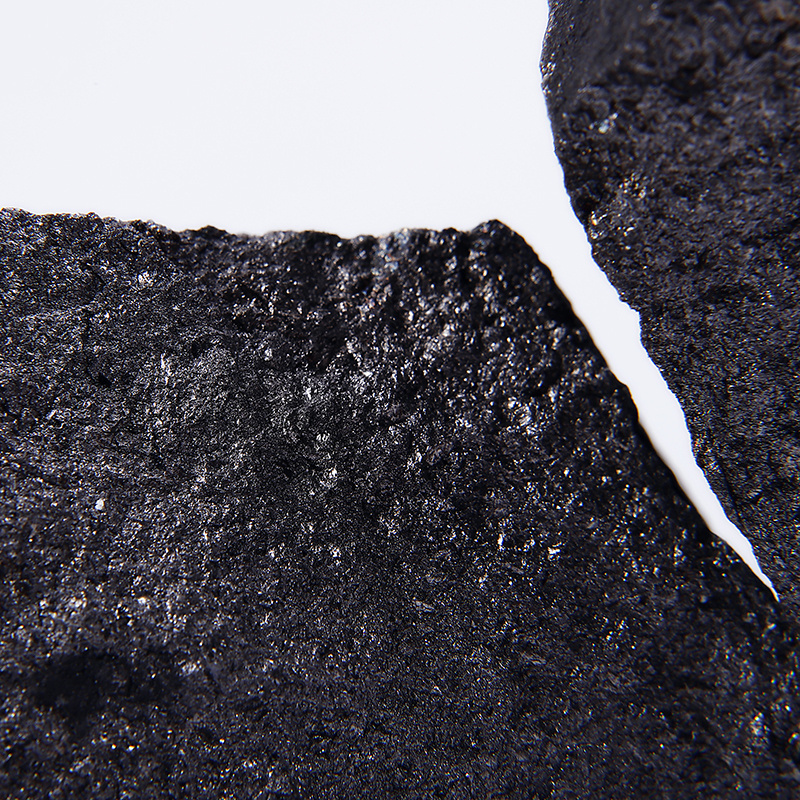

Product Display

|

Product Name

|

Silicon Manganese

|

|

Model Number

|

6517, 6014, 6515

|

|

Size

|

0-3MM, 1-10MM, 10-100MM, Customized

|

|

Application

|

Steel Making

|

|

Chemical

|

Mn, Si, Fe, P, S

|

Introduction To Silicon Manganese

Silicon-manganese alloy is an alloy composed of manganese, silicon, iron and a small amount of carbon and other elements. Its consumption occupies the second place in electric furnace ferroalloy products. Manganese and silicon in manganese-silicon alloys have a strong affinity with oxygen. When manganese-silicon alloys are used in steelmaking, the melting points of MnSiO3 and Mn2SiO4 produced by deoxidation products are 1270 °C and 1270 °C, respectively. 1327℃, it has the advantages of low melting point, large particle size, easy to float, and good deoxidation effect. Under the same conditions, using manganese or silicon alone for deoxidation, the burn loss rates are 46% and 37%, respectively, while with manganese-silicon alloy deoxidation, the burn loss rates of both are 29%.

It has been widely used in steelmaking, and its output growth rate is higher than the average growth rate of ferroalloys and higher than the growth rate of steel. It has become an indispensable composite deoxidizer and alloy additive in the iron and steel industry. Manganese-silicon alloys with carbon content below 1.9% are also semi-finished products used in the production of medium and low carbon ferromanganese and electro-silicon thermal manganese.

Ingredient Content

Mn: 65-66%

Si: 17-22%

Fe: 15% max

P: 0.25% max

S: 0.04% max

Application

Silicon-manganese alloy is mainly used as the intermediate material of deoxidizer and alloying agent in iron and steel production, and also the main raw material of medium and low carbon ferromanganese production.

Silicon-manganese alloy is an alloy composed of manganese, silicon, iron and a small amount of carbon and other elements. Its consumption occupies the second place in electric furnace ferroalloy products. Silicon and manganese in silicon-manganese alloys have a strong affinity with oxygen. When silicon-manganese alloys are used in steelmaking, the resulting deoxidation products MnSiO3 and MnSiO4 melt at 1270°C and 1327°C respectively, with low melting point, large particles and easy to float. , good deoxidation effect and so on. Under the same conditions, using manganese or silicon alone for deoxidation, the burning loss rate is 46% and 37%, respectively, while with silicon-manganese alloy deoxidation, the burning loss rate of the two is 29%. Therefore, it has been widely used in steelmaking, and its output growth rate is higher than the average growth rate of ferroalloys, and it has become an indispensable composite deoxidizer and alloy additive in the iron and steel industry. Silicon-manganese alloys with a carbon content of less than 1.9% are also semi-finished products used for the production of medium and low carbon ferromanganese and electro-silicothermal metal manganese. In ferroalloy production enterprises, the silicon-manganese alloy used in steelmaking is usually called commercial silicon-manganese alloy, the silicon-manganese alloy used in smelting low carbon iron is called self-use silicon-manganese alloy, and the silicon-manganese alloy used in metal smelting is called high silicon alloy. Silicon manganese alloy. Manganese can be combined with silicon to form silicides MnSiO3, MnSiO and MnSiO3. It can be seen from the silicon manganese state diagram that the most stable silicide is MnSi. Due to the negative value of the free energy of manganese silicide generation, it is far greater than the negative value of the free energy of manganese carbide production. The higher the silicon content in the silicon-manganese alloy, the lower the carbon content.

Main Products

Hot Searches