- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Metal

-

Certificate:

-

SGS

-

Keywords:

-

Two part component auto glass pu sealant polyurethane

-

Package:

-

Cartridge: 300ml Sausage: 600ml

-

Viscosity:

-

Strong

-

Feature:

-

High Temperature Resistance

-

Shelf life:

-

12 Months

-

Quality:

-

100%silicone

Quick Details

-

CAS No.:

-

7085-85-0

-

Place of Origin:

-

China

-

Color:

-

White

-

Application:

-

Metal

-

Certificate:

-

SGS

-

Keywords:

-

Two part component auto glass pu sealant polyurethane

-

Package:

-

Cartridge: 300ml Sausage: 600ml

-

Viscosity:

-

Strong

-

Feature:

-

High Temperature Resistance

-

Shelf life:

-

12 Months

-

Quality:

-

100%silicone

Description

SV-8800 is two components, high modulus; neutral curing silicone sealant specifically developed for assembly of high performance insulated glass units as secondary sealing material.

|

Name

|

SV-8800

|

|

Basis Material

|

two parts silicone sealant

|

|

scope of application

|

glass curtain wall structural glazing

structural bonding glass curtain wall glass and metal

|

|

Volume

|

190L

|

|

colour

|

black

|

|

packing

|

barrel

|

Features

2. UV resistance

3. Low vapor and gas transmission

4. Primeryless adhesion to coated glass

5. 100% compatible to SV-8890

Application

It is a two-component silicone that offers variable work life with high bonding strength to maintain the integrity of insulating glass unit, suits both commercial and residential IGU.

Product Parameter

|

Item

|

|

Standard

|

Result

|

|

|

Sag degree

|

Upright(mm)

|

≤3

|

0

|

|

|

|

parallel

|

No deformation

|

No deformation

|

|

|

Skin dry time(h)

|

|

≤3

|

0.6

|

|

|

Extrude,ml/min

|

|

≤10

|

1.58

|

|

|

Tensile Strength(Mpa)

|

23℃

|

1.58

|

0.96

|

|

|

Adhesion properties

|

|

No destroy

|

No destroy

|

|

Product Description

Two-component polyurethane insulating glass adhesive is a neutral curing, mainly for the second sealed insulating glass. The formulation of the product has a high modulus, high strength properties to meet the requirements of insulating glass equipment

neutral curing, glass, metal has good adhesion, no pollution to the coated glass, no corrosion;

The shelf life is 12 months in Group A and 9 months in Group B, when stored at -20 ℃ ~ 27 ℃ in dry place.

A component is white, B component is black, the mixing ratio of A: B1 = 10: 1 (volume ratio), after mixing gray-black, the specific sizing method, see the relevant specification.

|

Automatic sealing

|

A Part 190L/Barrel

|

B Part 19L/Barrel

|

|

|

|

|

|

|

|

|

|

Manual

|

A Part 19L/ Barrel

|

B Part 300ml/tube

|

|

|

|

|

|

|

|

|

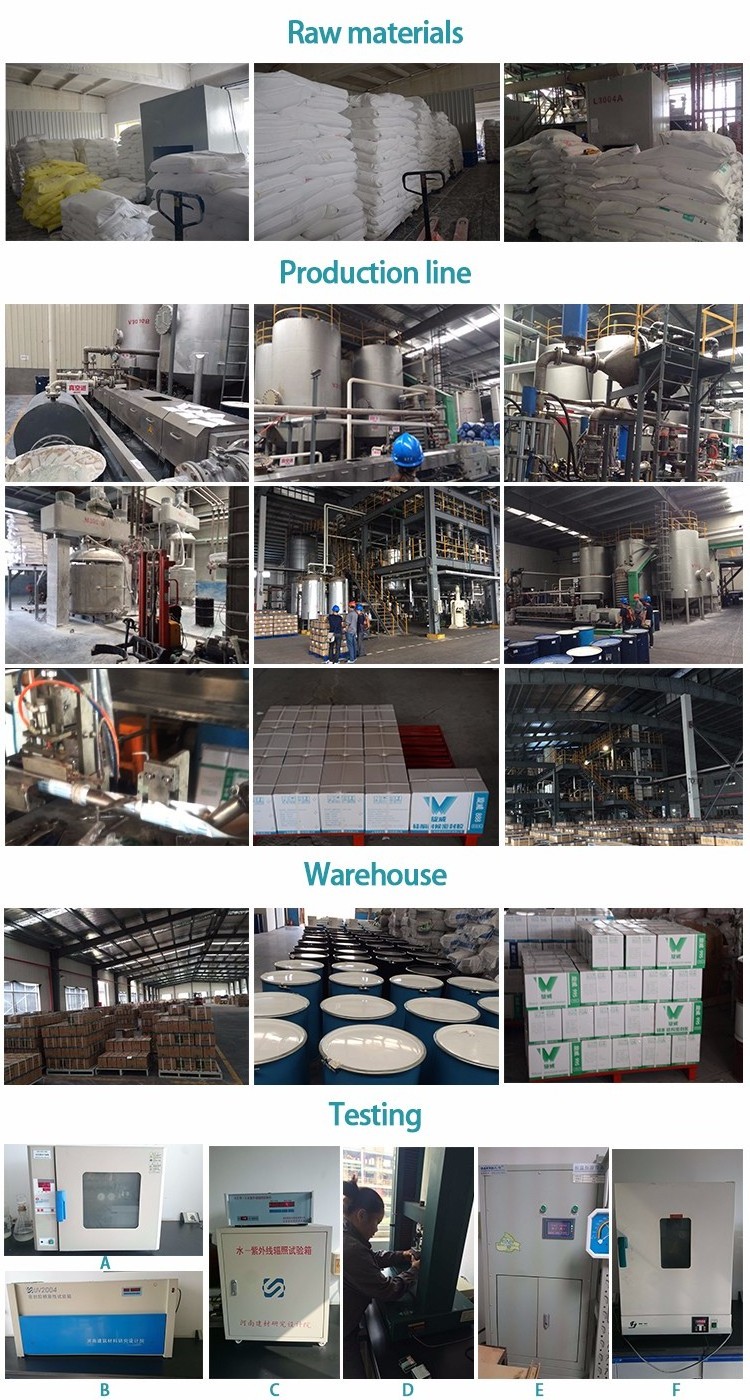

Welcome to visit our factory at any time

|

Testing A

|

Equipment Name

|

Electric thermostaticdrying oven

|

|

|

||

|

|

Testing purposes

|

Test the volatilization of silicone sealant materials and silicone sealant products

|

|

|

||

|

Testing B

|

Equipment Name

|

Sealant Compatibility Test Chamber

|

|

|

||

|

|

Testing purposes

|

Test the adhesion of the silicone sealant to the substrate

|

|

|

||

|

Testing C

|

Equipment Name

|

UV weathering test machine

|

|

|

||

|

|

Testing purposes

|

Test the weather resistance of silicone sealants in simulated natural environments

|

|

|

||

|

Testing D

|

Equipment Name

|

Tensile testing machine

|

|

|

||

|

|

Testing purposes

|

Detection of tensile strength of sealant adhesive, bond failure area, the maximum tensile strength at a certain temperature elongation

|

|

|

||

|

Testing E

|

Equipment Name

|

constant temperature and humidity device

|

|

|

|

|

Testing purposes

|

Test the weather resistance of silicone sealant

|

|

|

|

Testing F

|

Equipment Name

|

high temperature oven

|

|

|

|

|

Testing purposes

|

This experiment simulates the high-temperature environment, accelerates the thermal oxidation of the sealant in the air, so as to determine the high-temperature aging resistance of the sealant

|

|

|

Our factory

The factory is located in Quzhou, Zhejiang High-tech Industrial Park, covers an area of 330 acres, more than 500 employees, including college education more than 200 people, we are new fluorine-silicon industry in Zhejiang Province technological innovation pilot units

Our client visit our factory

WELCOME TO VISIT US --- SIWAY

Big smile on Majesties face. Silicone sealant in your home, Money rushes to you.

More Professional, More Patient, More Responsibility.

Our Siway team always try our best to help all of you.

Similar Product

|

SV-666

|

STRUCTURAL SILICONE SEALANT

|

|

SV-777

|

WEATHER-PROOFING SILICONE SEALANT

|

|

SV-888

|

STONE SILICONE SEALANT

|

|

SV-995

|

NEUTRAL SILICONE SEALANT

|

What can we do for you?

We are silicone sealant, silicone sealant for curtain wall , silicone sealant for door and window suppliers . Products are widely used in construction, curtain walls, doors and windows and interior decoration, electronics and other fields.

We can provide solutions for different use cases, we have variety of silicone sealant, foam sealant, providing OEM services to meet the procurement needs of different countries and regions