* Ailin coating has a professional and efficient working team.Our professional senior engineer to find the best solutions for you.

* You'd better offer the specifications of your workpiece to us.

* The production process (if you are new on coating, we will give you specialized suggestion of the whole work)

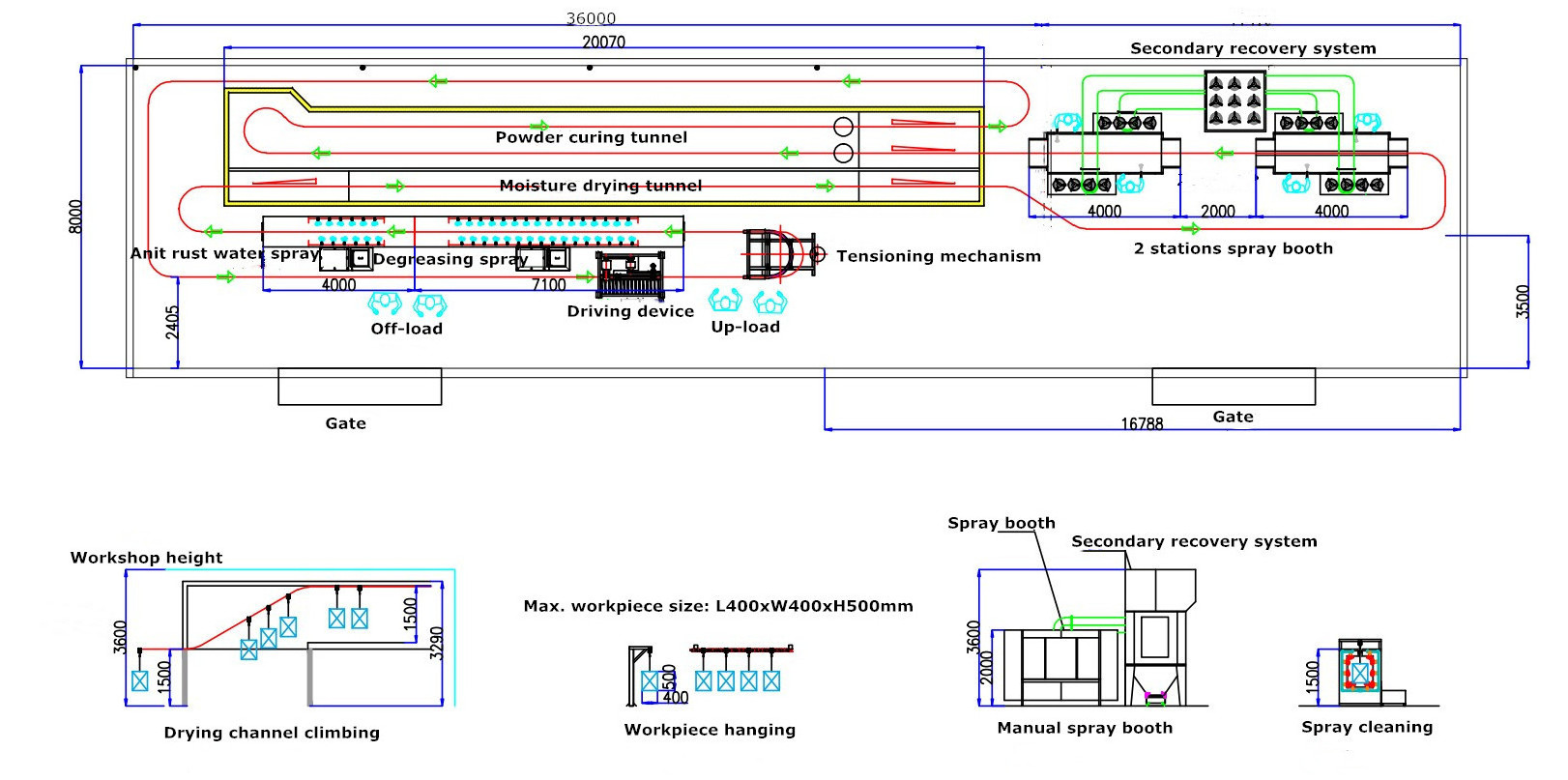

* The size of the workpiece (including the max length, width, height and weight)

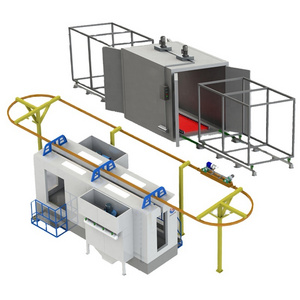

* The capacity (how many pcs in 8 hours)

* The available size of your factory (including the length, width and height)

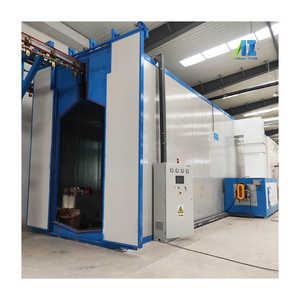

* The heating power (electricity, gas or diesel oil )

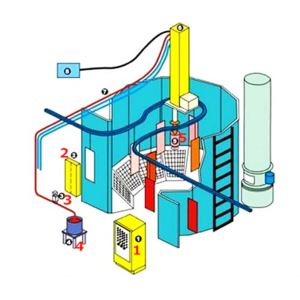

* Automatic painting or manual painting pre-treatment process or not, if you do, automatic pre treatment, dipping pre-treaiment or sand blasting.

* How many colors do you need to change every day.

* The local electricity conditions(_v/_phase/_hz) The any special requirements about the package.

* Our powder coating system's design and production all according to customer's requirement(capacity, size of product, size of workshop).