- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China (Mainland)

-

Brand Name:

-

Langle

-

Voltage:

-

220v

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

50 kg

-

product name:

-

Electric Light Heavy Duty System Rubber Pvc Drive Diy Conveyor Belt

-

color:

-

customized, silver, black

-

style:

-

belt conveyor, roller conveyor

-

Size:

-

1m, 2m, 3m, customized

-

Accessories:

-

Mounting Clips, bracket, motor, fastener

-

Delivery time:

-

15~25 Days

-

Certification:

-

ISO 9001

-

Surface treatment:

-

Silver Anodized

-

Installation:

-

Corner Mounted

Quick Details

-

Power:

-

As the model you choose

-

Warranty:

-

2 years

-

Width or Diameter:

-

500mm

-

Place of Origin:

-

China (Mainland)

-

Brand Name:

-

Langle

-

Voltage:

-

220v

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

50 kg

-

product name:

-

Electric Light Heavy Duty System Rubber Pvc Drive Diy Conveyor Belt

-

color:

-

customized, silver, black

-

style:

-

belt conveyor, roller conveyor

-

Size:

-

1m, 2m, 3m, customized

-

Accessories:

-

Mounting Clips, bracket, motor, fastener

-

Delivery time:

-

15~25 Days

-

Certification:

-

ISO 9001

-

Surface treatment:

-

Silver Anodized

-

Installation:

-

Corner Mounted

Product Description

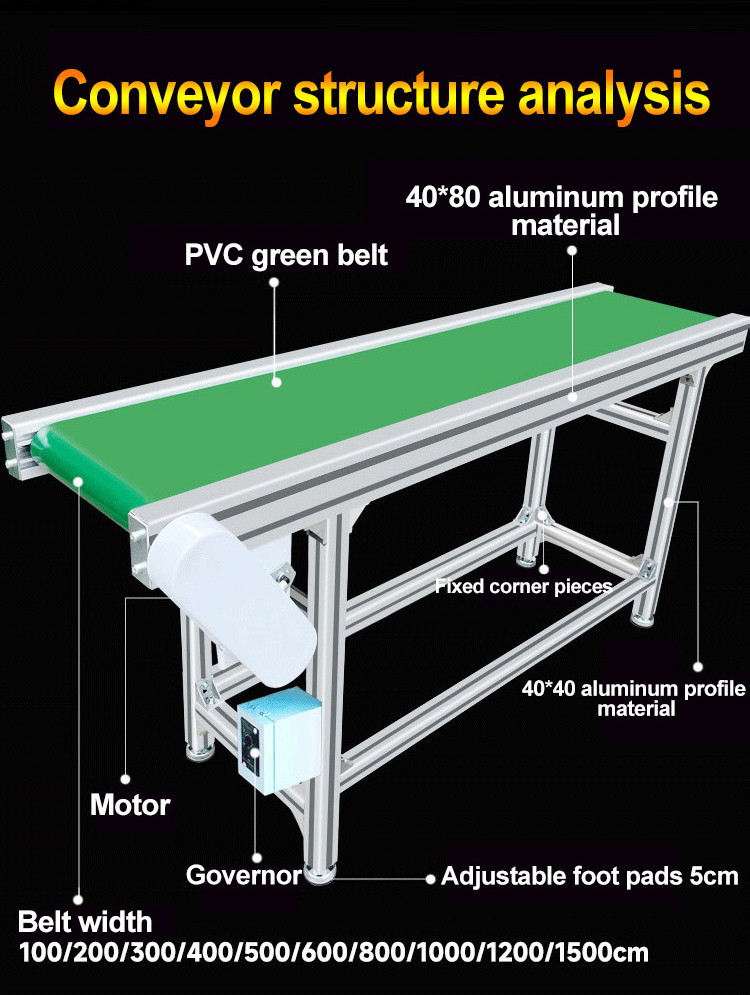

Description of PVC Belt Conveyor:

1. 12mm thickness structure with Aluminum material

2. 3mm thickness PVC belt

3. Normal height 90±10cm adjustable

4. Width and length and height can made according to customer requirement

5. Speed adjustable

1. 12mm thickness structure with Aluminum material

2. 3mm thickness PVC belt

3. Normal height 90±10cm adjustable

4. Width and length and height can made according to customer requirement

5. Speed adjustable

|

Product Name

|

Mining conveyor belting roller profile sliding chevron belt conveyor guide rails conveyor line

|

|

Conveyor Material

|

PVC conveyor, belt conveyor, aluminum frame coveyor, steel conveyor

|

|

Frame option

|

Aluminum profile, stainless steel, carbon steel

|

|

Process

|

Assembly by screw nut, welding

|

|

Major parts

|

PVC belt, frame, motor, speed controller, power, roller tracker, metal parts

|

|

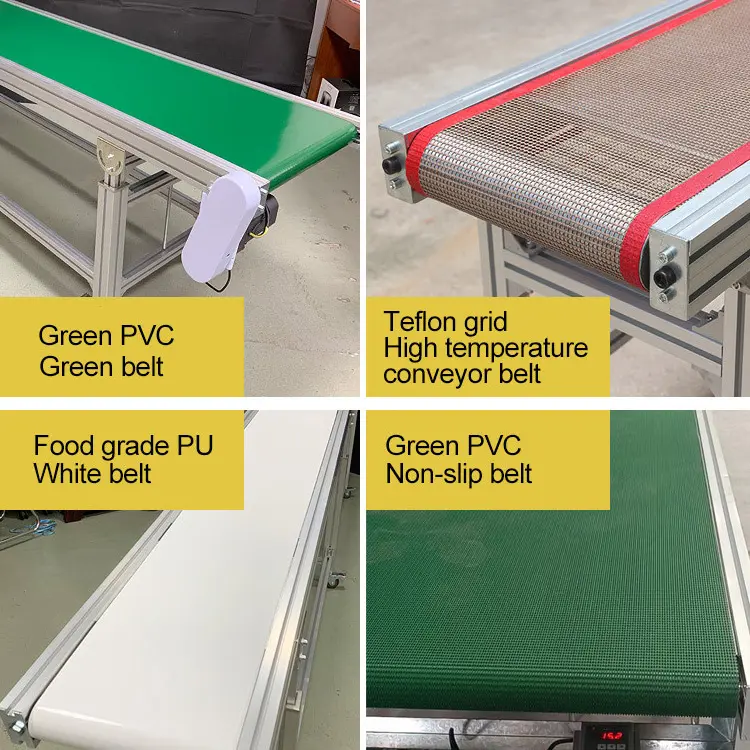

Belt color choice

|

White, Blue, Green, Black

|

|

Belt option

|

PVC, steel, PU, mesh, roller

|

|

Production leadtime

|

10~15days for small quantity, 30days for over 10sets

|

|

Shipping Terms

|

EXW, FOB, C&F or others can be discussed

|

|

Application

|

Production line, Assembly line, Automatic production line, Packaging driver, cargo driver line

|

|

Conveyor power

|

Can be customized as per your country voltage

|

|

Warranty

|

Motor - 3 years, other parts - 1 year

|

|

Shipping method

|

Conveyor can be semi-assembled package, and put into wood box to avoid damage

|

1.Belt part

-optional material: PU, PVC, Rubber, Anti-static

-compact structure

-adjustable elastic

-Firm with acid, corrosion and insulation

-Not easy ageing and high strength

2.Motor part

-positive inversion of belt

-brand new motor

-reliable installation

-quiet and more smooth operation

-excellent energy conversion construction type

-long service life with professional barnd motor

3.Support frame

-40mm*80mm model size, or more heavy duty profiles

-aluminum alloy, stainless steel or special request

-strong mechanical strength

-stable operation and extensively insensitive to jarring or vibration

4.Fixed type

-removability with wheels

-fixed feet on the ground or with floor element with no moving

-optional material: PU, PVC, Rubber, Anti-static

-compact structure

-adjustable elastic

-Firm with acid, corrosion and insulation

-Not easy ageing and high strength

2.Motor part

-positive inversion of belt

-brand new motor

-reliable installation

-quiet and more smooth operation

-excellent energy conversion construction type

-long service life with professional barnd motor

3.Support frame

-40mm*80mm model size, or more heavy duty profiles

-aluminum alloy, stainless steel or special request

-strong mechanical strength

-stable operation and extensively insensitive to jarring or vibration

4.Fixed type

-removability with wheels

-fixed feet on the ground or with floor element with no moving

Why Choose LANGLE?

1. 10 years experience in the industry of Servo Motor Industrial Robotic Arm .

2. All components are new, some core components are imported from German(Festo/Igus), Japan(NSK/THK/Omron/Panasonic), France(Schneider/Legris), Italy(Elatech) etc.

3. We do 100% testing before shipment.

4. Warranty are 12 months for all products.

5. Provide professional automation system by customize requirements, saveing time and cost for you, enjoy the one-stop shopping.

6. Stand by service, our engineer or technician will visit your esteemed company for installation and debugging of machine.

1. 10 years experience in the industry of Servo Motor Industrial Robotic Arm .

2. All components are new, some core components are imported from German(Festo/Igus), Japan(NSK/THK/Omron/Panasonic), France(Schneider/Legris), Italy(Elatech) etc.

3. We do 100% testing before shipment.

4. Warranty are 12 months for all products.

5. Provide professional automation system by customize requirements, saveing time and cost for you, enjoy the one-stop shopping.

6. Stand by service, our engineer or technician will visit your esteemed company for installation and debugging of machine.

Mining conveyor belting roller profile sliding chevron belt conveyor guide rails conveyor line, Aluminum in general, and aluminum extrusions in particular, offer a number of benefits relative to alternative materials and processes. Aluminium extrusion is often the most viable solution that meets the specific manufacturing needs of design flexibility, cost savings, product performance, and shorting design and assembling time.

The Advantage extrusion aluminum profile are included Lightweight, Strong, High in strength-to-weight material, Resilient,

Corrosion resistant, Excellent thermal conductors, Non-sparking, Excellent electrical conductors, Non-magnetic, Noncombustible & Nontoxic, Reflective, Seamless, Easily tailored, Quick-to-market, Easy to fabricate & assemble, Sustainable.

Langle can help you choose the appropriate alloy and design the optimum extrusion profile for your project and budgetary

requirement, and associated accessories are available as well to save your time to resource it.

1. Saving mould cost and shorten production time;

2. Shorting design and assembling time;

3. Associated accessories are available as well to save your time to resource it;

4. Controlling cost and providing more efficient working project;

5. Improving your systems and space management with our professional technical team.

The Advantage extrusion aluminum profile are included Lightweight, Strong, High in strength-to-weight material, Resilient,

Corrosion resistant, Excellent thermal conductors, Non-sparking, Excellent electrical conductors, Non-magnetic, Noncombustible & Nontoxic, Reflective, Seamless, Easily tailored, Quick-to-market, Easy to fabricate & assemble, Sustainable.

Langle can help you choose the appropriate alloy and design the optimum extrusion profile for your project and budgetary

requirement, and associated accessories are available as well to save your time to resource it.

1. Saving mould cost and shorten production time;

2. Shorting design and assembling time;

3. Associated accessories are available as well to save your time to resource it;

4. Controlling cost and providing more efficient working project;

5. Improving your systems and space management with our professional technical team.

When selecting a Belt Conveyor, you can consider the following factors:

1. Load requirements: Determine the type, weight, and dimensions of the materials you need to convey. This will determine the selected Belt Conveyor's load capacity and size requirements.

2. Application environment: Consider the conditions of the working environment, such as temperature, humidity, dust, and

corrosive factors. Choose durable and corrosion-resistant materials and coatings suitable for that environment.

3. Conveying distance and speed: Determine the required conveying distance and speed to select a Belt Conveyor with the

appropriate belt width and drive force.

4. Safety requirements: Consider safety requirements such as emergency stop devices, protective covers, warning systems, etc. Ensure that the selected Belt Conveyor complies with relevant safety standards and regulations.

5. Maintenance requirements: Consider the convenience of maintenance and upkeep. Choose a design that is easy to maintain and has readily replaceable components.

6. Cost-effectiveness: Consider factors such as equipment price, energy consumption, maintenance costs, and lifespan to select a Belt Conveyor that offers good value for money.

7. Supplier reputation: Choose a Belt Conveyor supplier with experience, a good reputation, and a track record of providing

high-quality after-sales service.

It is important to assess and compare based on your specific needs, ensuring that the selected Belt Conveyor meets your

requirements and possesses reliability, durability, and safety.

1. Load requirements: Determine the type, weight, and dimensions of the materials you need to convey. This will determine the selected Belt Conveyor's load capacity and size requirements.

2. Application environment: Consider the conditions of the working environment, such as temperature, humidity, dust, and

corrosive factors. Choose durable and corrosion-resistant materials and coatings suitable for that environment.

3. Conveying distance and speed: Determine the required conveying distance and speed to select a Belt Conveyor with the

appropriate belt width and drive force.

4. Safety requirements: Consider safety requirements such as emergency stop devices, protective covers, warning systems, etc. Ensure that the selected Belt Conveyor complies with relevant safety standards and regulations.

5. Maintenance requirements: Consider the convenience of maintenance and upkeep. Choose a design that is easy to maintain and has readily replaceable components.

6. Cost-effectiveness: Consider factors such as equipment price, energy consumption, maintenance costs, and lifespan to select a Belt Conveyor that offers good value for money.

7. Supplier reputation: Choose a Belt Conveyor supplier with experience, a good reputation, and a track record of providing

high-quality after-sales service.

It is important to assess and compare based on your specific needs, ensuring that the selected Belt Conveyor meets your

requirements and possesses reliability, durability, and safety.

Hot Searches