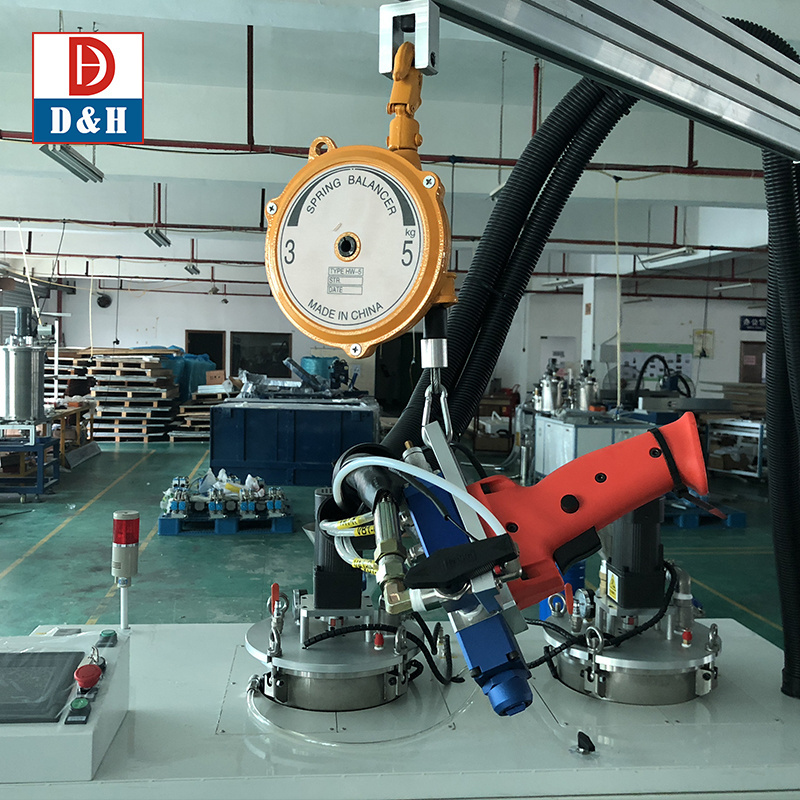

AB glue mixing machine 2k resin dispenser machine 2 part resin dispensing machine with hand gun

Multiple configuration, suitable for a variety of products

High versatility and high cost performance

Suitable for various products

Can be used with production lines

Operation:Manual/Automatic

Meter Pump:Gear pump/Screw pump/Double cylinder plunger pump

Flow Control: Digital Input

Programming method: teaching programming

Meter Pump:Gear pump/Screw pump/Double cylinder plunger pump

Flow Control: Digital Input

Programming method: teaching programming