1).automatic vertical single head uncoiler : 1 set

a.Using hand tightening design, Coil ID:460mm-520mm, coil OD:1400mm, Loading:2000kg

b.Frequency conversion automatic uncoiling

c.Power:2.2KW

- Product Details

- {{item.text}}

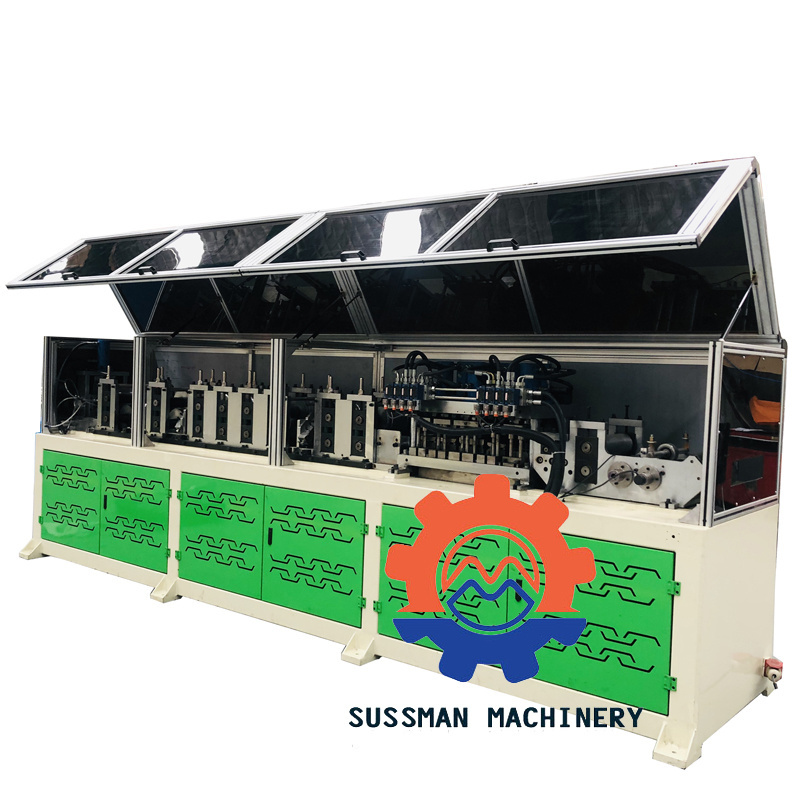

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sussman

-

Voltage:

-

380V, 50Hz, 3 phase (can be customized)

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

4.5m*800m*1.0m

-

Weight:

-

3000 kg

-

Rolling thinckness:

-

0.6-1.2mm G350-G550MPa

-

Feeding width:

-

142 mm or customized

-

Roller material:

-

45#steel Chrome Plated

-

Main power:

-

7.5KW servo motor

-

Hydraulic motor:

-

7.5KW

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Roller station:

-

11 stations

-

Control system:

-

Fully Automatic Computer Control

-

Product Keywords:

-

light steel framing machine

-

Design software:

-

Vertex BD Software or CSV file

Quick Details

-

Marketing Type:

-

cheaper price

-

Work Pressure:

-

15KW

-

Production Capacity:

-

15-30m/min

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sussman

-

Voltage:

-

380V, 50Hz, 3 phase (can be customized)

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

4.5m*800m*1.0m

-

Weight:

-

3000 kg

-

Rolling thinckness:

-

0.6-1.2mm G350-G550MPa

-

Feeding width:

-

142 mm or customized

-

Roller material:

-

45#steel Chrome Plated

-

Main power:

-

7.5KW servo motor

-

Hydraulic motor:

-

7.5KW

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Roller station:

-

11 stations

-

Control system:

-

Fully Automatic Computer Control

-

Product Keywords:

-

light steel framing machine

-

Design software:

-

Vertex BD Software or CSV file

Light gauge steel roll forming machine is the most popular machine and its product includes C U stud, track, furring channel, main channel (primary channel), carrying channel, wall angle, corner angle, edge bead, shadow line wall angle, top hat, T bar machine, etc. Our machine has an extensive use in Drywall system, Ceiling system and Floor system. Thickness is normally 0.5-0.9mm or up to 1.2mm. Raw material could be: cold-rolled steel, Galvanized steel, PPGI, high-tensil steel.

In Drywall system and drywall partition system, we could provide roll forming machine as following:

1. Metal stud roll forming machine

2. Metal track roll forming machine

3. Main Channel roll forming machine

4. Omega hat furring channel roll forming machine

5. Conner bead (Angle bead) roll forming machine

6. T grid bar roll forming machine

In Construction Industries, we are able to manufacture more machines like C Z purlin roll forming machine, metal deck(floor deck) roll forming machine, vigacero roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine, etc.

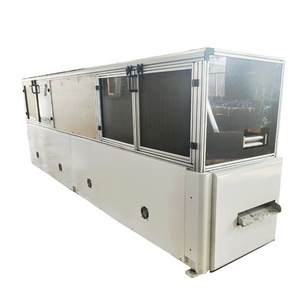

|

Thickness

|

0.7-1.2mm(G300-G550Galvanzied coils and Aluzinc )

|

|

Feeding width

|

About 182mm

|

|

Standard Producing speed

|

About 300-700m/h

|

|

Max producing speed

|

About 1500m/h

|

|

Main motor

|

7.5kw Servo motor

|

|

Power supplier

|

220V 60Hz 3phases according to your request

|

|

Hydraulic station

|

7.5kw Motor

|

|

Hydraulic tank capacity

|

About 100L

|

|

Hydraulic cooling

|

Fan cooling with Accumulator

|

|

Hydraulic pressure

|

Manually set

|

|

Host cordless remote control

|

Standard

|

|

Frame and punching dies

|

Screw hole, chamfer, web hole, flange cut, pipe hole, suspension, cutting,

|

|

Product accuracy+-

|

0.5mm

|

|

CNC inkjet-printer

|

Inter jet printer Video jet

|

|

Size

|

About 4700*950*1200mm

|

|

Weight

|

About 3500kg

|

|

Color

|

Standard or according to your request

|

|

De-colier

|

Bearing 2 tonne, automatically decoiler

|

|

PLC

|

Panasonic brand

|

|

Electrical parts

|

Schneider brand, encoder:Omron

|

Automatic decoiler

Title goes here.

1). Frame: Using steel plate welding, the overall annealing to stress treatment, to ensure long-term use without deformation; and CNC machining center processing to ensure dimensional accuracy.

2). Rolling mould: Cr12mov die steel, after vacuum hardened HRC60-62 ° to refine the hole and the end of the face, CNC lathe

finishing the roller surface.

3). Drive system: Servo motor and reducer linkage, between the wheel with precision hard tooth gear oil immersion operation, to

ensure that the use of long time without wear.

4). Punching mould

Die model material are used S45C tool steel, mold insert with D2 or SKD11 high-quality steel, mold parts with Japan's rice

products.

2). Rolling mould: Cr12mov die steel, after vacuum hardened HRC60-62 ° to refine the hole and the end of the face, CNC lathe

finishing the roller surface.

3). Drive system: Servo motor and reducer linkage, between the wheel with precision hard tooth gear oil immersion operation, to

ensure that the use of long time without wear.

4). Punching mould

Die model material are used S45C tool steel, mold insert with D2 or SKD11 high-quality steel, mold parts with Japan's rice

products.

control system

Control Device:One laptop, a control box inside of based frames of the machine

Design Software: Vertex BD from AU

Printing Device: USA Printing Device for spray logo and installation number

Remote-control Device:Wireless remote-controller controls machine to go forward or back or stop

Main brand:

PLC(Delta),Relay(Schneider),Proximity switch(Schneider),Encode(Omron) Servo Motor

Hot Searches