- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

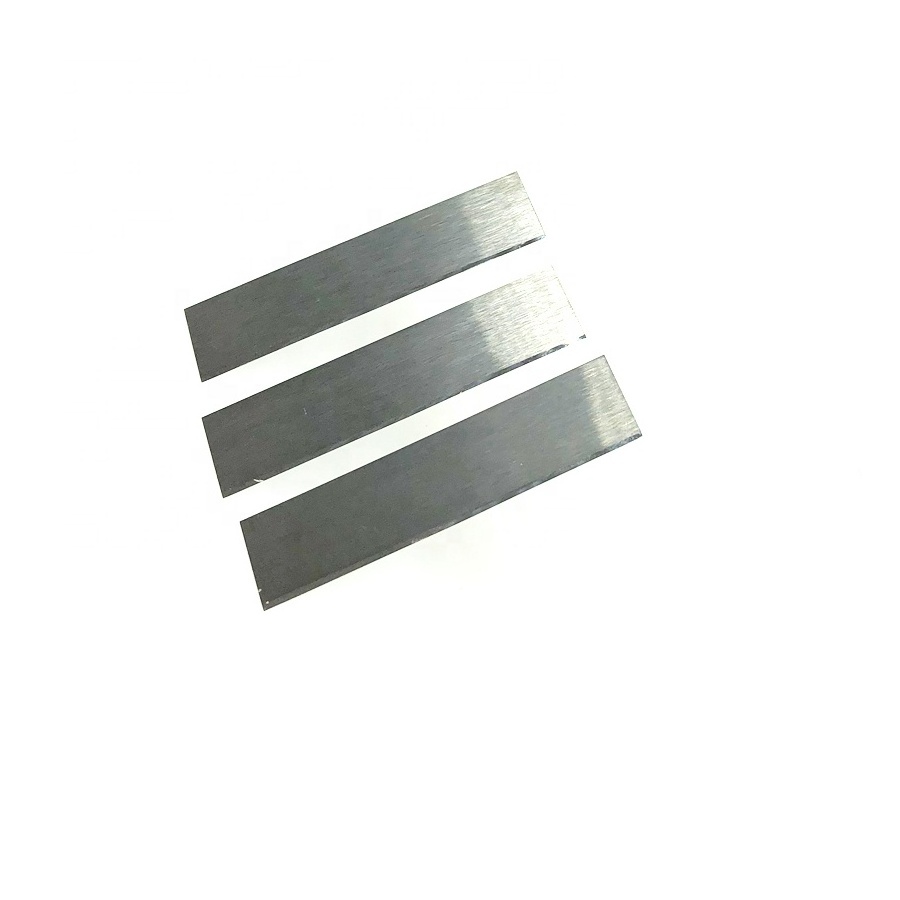

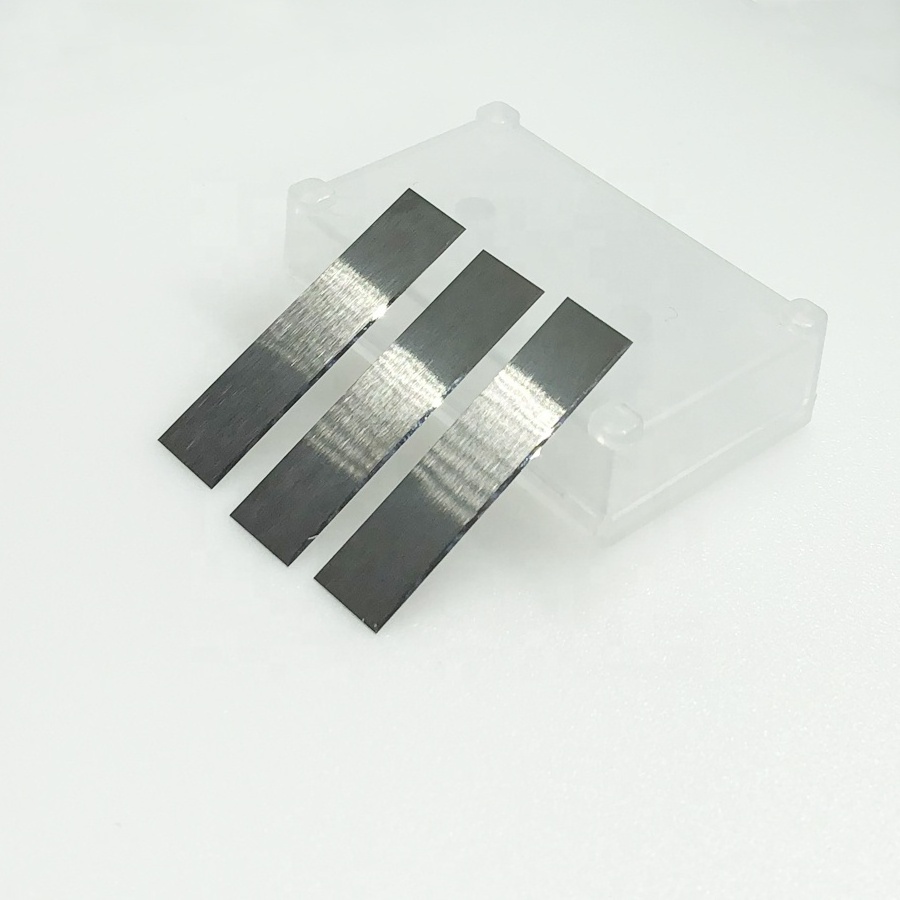

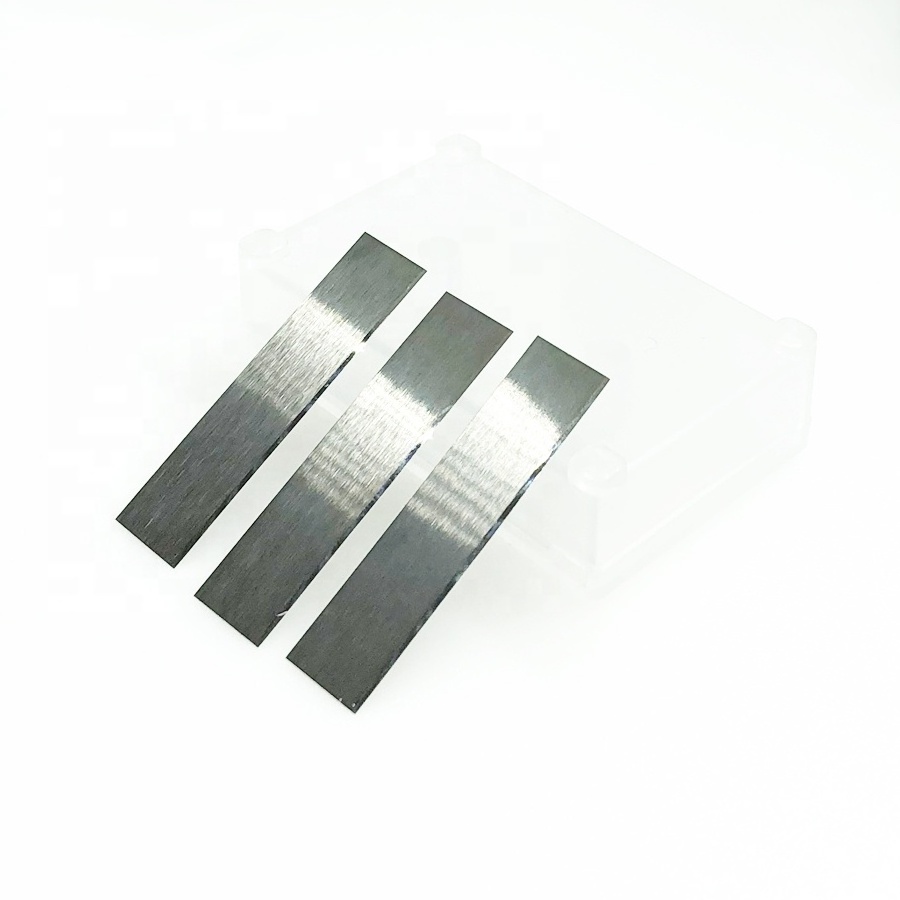

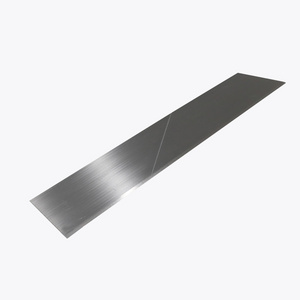

Tungsten Carbide Tobacco Leaf Fiberglass Long Cutting Knife

-

Material:

-

100% Virgin Tungsten Carbide

-

Hardness:

-

HRA85~92

-

Advantage:

-

Factory produced with competitive price and quality

-

Application:

-

For cigar making machine

-

Feature:

-

High hardness and durability

-

Surface condition:

-

Mirror finishing

-

Cutting Thickness:

-

Based on material

-

Shape:

-

Customized tungsten carbide long cutting knife for cigar making

Quick Details

-

Core Components:

-

Blade

-

Type:

-

Cutter blade

-

Brand Name:

-

Davedew, Davedew

-

Product name:

-

Tungsten Carbide Tobacco Leaf Fiberglass Long Cutting Knife

-

Material:

-

100% Virgin Tungsten Carbide

-

Hardness:

-

HRA85~92

-

Advantage:

-

Factory produced with competitive price and quality

-

Application:

-

For cigar making machine

-

Feature:

-

High hardness and durability

-

Surface condition:

-

Mirror finishing

-

Cutting Thickness:

-

Based on material

-

Shape:

-

Customized tungsten carbide long cutting knife for cigar making

OEM/ODM Tungsten Carbide Tobacco Leaf Fiberglass Long Cutting Knife for Cigar Making Machine Blade

OEM/ODM Tungsten Carbide Tobacco Leaf Fiberglass Long Cutting Knife for Cigar Making Machine Blade

Tungsten carbide long cutting knife for cigar making machine is manufactured from

tool steel

and

special alloy steel

according to the application requirement. Our factory have a manufacturing facility to produce sizes up to 650mm in diameter and slit up to 16mm thick coils. We also can manufacture precision cutting tools with the thickness tolerance of 0.0015mm and flatness of 0.0025mm depending on the OD and thickness you need

.

This

is possible with our precise Lapping Machines. Closer tolerances & special surface finishes are also possible. All the datas are all based on your requirements.

An in-house deep cryogenic treatment gives the knife a finer microstructure which enhances the life of the tool.

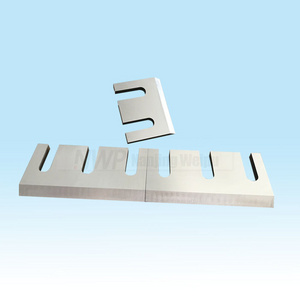

Tungsten carbide long cutting knife for cigar making machine are manufactured using through hardened tool steel. Atlas offers lightweight and also Ultra lightweight spacers which are nearly 65-70% lighter than the conventional steel spacer. This makes the job of the operator easier and causes less fatigue

. To

ease assembly and removal of tools, we offer Split design. The spacers can also be lapped to the highest level of precision.

Bonded stripper rings are made from alloy tool steel bonded with oil and abrasion resistant material such as Nitrile Rubber(Buna N) or Polyurethane. These are available in various shore hardness and colors to match your specific requirement.

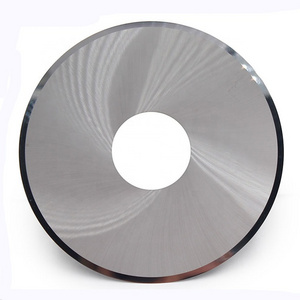

Separator discs are customized made exactly to user specifications. We offer single/double bevel angle and various thickness for you to choose. Available to a maximum hardness of 58/60 Rockwell, steel separator discs are made from the finest steel and guarantee a long-lasting, dependable performance at competitive prices. These can also be chrome plated to reduce friction between the plate face and the slit edge.

>>4. Reduction in start-up and end of line waste;

>>5. Better overall cutting performance in high heat and high speed cutting environments.

Application of blade manufacturer tungsten carbide long cutting knife for cigar making machine:

We manufacture carbide knives and blades for Paper, Metal, Film and Foils, Textiles, Corrugated Cardboard, PCB, Plastic, Wood, Asbestos, Converting, Cloth, Fibre, Rubber, Printing, Packaging, Tobacco, Nonwovens,Tube and Pipe, Bookbinding, and many other industries. Knives and Blades can be made from different types of material, according to our customers requirement.

Materials details:

| Grade | ISO Grade | WC% | CO% | Other | Grain Size | Hardness (HRA±0.3) | Bending Strength | HIP(±200) | Density(g/cm³)±0.05 |

| YG8 | K20 | 92 | 8 | / | 1.6-1.8 | 90.5 | 2500 | 3200 | 14.7 |

| GH8 | K20 | 91 | 8.5 | 0.5 | 1.4-1.6 | 91.5 | 2500 | 3300 | 14.6 |

| YG6X | K10 | 93.5 | 6 | 0.5 | 1-1.2 | 92.3 | 2400 | 3000 | 14.8 |

| YG10X | K30 | 89.4 | 10 | 0.6 | 0.6-0.8 | 91.8 | 2800 | 3200 | 14.5 |

| YG15A | K40 | 84.4 | 15 | 0.6 | 1-1.2 | 90 | 2600 | 3000 | 14 |

| GH05UF | K10 | 93.4 | 6 | 0.6 | 0.6-0.8 | 93.5 | 2500 | 3200 | 14.8 |

| GU10UF | K10 | 93.8 | 6 | 0.2 | 0.6-0.8 | 92.9 | / | 3500 | 14.8 |

| GH15UF | K20 | 91.3 | 8.5 | 0.7 | 0.4-0.6 | 93 | / | 4200 | 14.5 |

| GH20UF | K30 | 89.4 | 10 | 0.6 | 0.6-0.8 | 92.5 | 3000 | 3500 | 14.5 |

HIP process

1.Fine porosity would be remained in Powder metallurgy of processing for alloy steel packaging industry blades for food processing, which will be the beginning of destroy of products.

2.To remove this fine porosity, Davedew produce products through HIP Process.

3.This process is progressed under the high temperature and pressure, and put the identical pressure on whole surface of product.

4.At this time, a fine porosity would be removed, and effected on improving high strength.