- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm, Customized design

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

HONGFA

-

Voltage:

-

380V or as customer local request

-

Dimension(L*W*H):

-

7100*1500*3000mm

-

Weight (KG):

-

6200 kg

-

Pallet Type:

-

BAMBOO / PVC /GMT

-

Pallet Size:

-

850*680*25mm

-

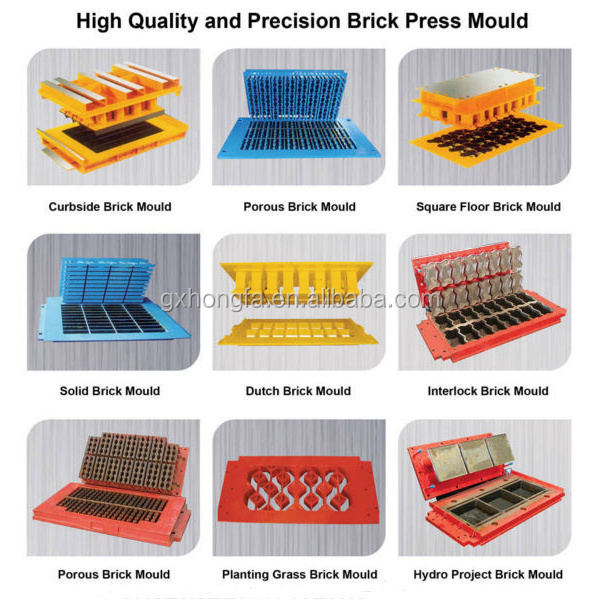

Brick/Block Mould:

-

As customized

-

Factory Layout Design:

-

Yes

-

Worker:

-

3-5 Workers

-

After-sales Service (A):

-

Free spare parts

-

After-sales Service (B):

-

Video technical & Online support

-

Certificate:

-

CE, ISO9001

Quick Details

-

Type:

-

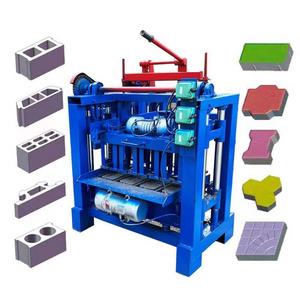

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other

-

Brick Raw Material:

-

Cement, stone, fly ash etc.

-

Production Capacity (Pieces/8 hours):

-

57,600pcs of standard solid block / shift

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm, Customized design

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

HONGFA

-

Voltage:

-

380V or as customer local request

-

Dimension(L*W*H):

-

7100*1500*3000mm

-

Weight (KG):

-

6200 kg

-

Pallet Type:

-

BAMBOO / PVC /GMT

-

Pallet Size:

-

850*680*25mm

-

Brick/Block Mould:

-

As customized

-

Factory Layout Design:

-

Yes

-

Worker:

-

3-5 Workers

-

After-sales Service (A):

-

Free spare parts

-

After-sales Service (B):

-

Video technical & Online support

-

Certificate:

-

CE, ISO9001

WELCOME TO HONGFA MACHINERY

| (I ) Brief Introduction | |

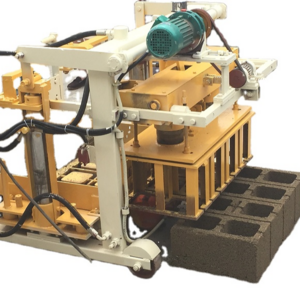

| A | The machine can serve several purposes and can produce pavement bricks, riverside bricks, revetment bricks, square bricks, grassed bricks and so on with different moulds. |

| B | Low frequency in feeding material, high frequency vibration. Platform vibrating works together with mould, so that the concrete can be fully fluidified and exhausted in two or three seconds to reach the high density. |

| C | The advanced technique of hydraulic-controlled proportion can handle the oil press and amount of the system freely, therefore, different materials can be able to produce the high quality products. |

|

(II) Control System |

|

PLC intelligent control. Man-machine interface, control system equipped with complete logic control, production program, malfunction diagnosis system and remote control function. So it doesn’t need a professional person but only need a simple trained one to the operator. |

| (III) TECHNICAL PARAMETERS | |

|

Overall Dimension |

7100*1500*3000 mm |

|

Rated pressure |

16MPa |

|

Main vibration form |

Platform vibration |

|

Acceleration of vibration |

15-20g |

|

Cycle Time |

15-25s |

|

Vibrating Frequency |

4500-5100 r/minute |

|

Vibration |

100KN |

|

Motors Power |

31.25KW |

|

Pallet Size |

850*680 mm (material option: PVC, GMT, bamboo,wood) |

|

Weight |

6.2T |

|

Raw Materials |

Crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, expanded perlite, and other industrial wastes |

- Concrete solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, curb stones, grass blocks, slope blocks, interlocking blocks, etc.

|

Type |

Block size (mm) |

Qty / mold (pcs) |

Molding cycle (s) |

Qty / 8 hrs (pcs) |

|

Hollow block |

400*200*200 |

6 |

15-25 |

8,700 - 11,500 |

|

Solid brick |

240*115*53 |

30 |

15-17 |

50,900 - 57,600 |

|

Color paver |

220*110*50 |

15 |

25-30 |

17,600 - 21,600 |

|

Please kindly add information as follows in your inquiry.

1. The exact size of blocks and bricks you need; 2. Picture/Drawing of your blocks; 3. The specific price please refer to your needs, such as details list. |

||||

-

If you want more such as shipping cost, machine video, catalog, details photos and so on, please send inquiry to

Ms.Sabrina

, or add

Whatsapp 008618587659617

, we will do the best to help you. Thanks.

Pre-sales

(1) Professional suggestions (raw material matching, machine selection, the condition of building factory, feasibility analysis for brick machine production line).

(2) Device model choice (recommend the best machine according to the raw material, capacity and the size of brick).

(3) Introduce the company file, product categories and production process.

During Sale

(1) Update the production scheduling in time.

(2) Quality supervision.

(3) Product acceptance.

(4) Shipping on time.

After-sales

(1) Training how to instal the machine, training how to use the machine.

(2) Engineers available to service machinery overseas.

(3) Recall clients regularly, get feedback in time, keep well communication with each other