- Product Details

- {{item.text}}

Quick Details

-

Cooling Capacity:

-

50ton

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DC

-

Voltage:

-

220V/380V

-

Power:

-

As per requirement

-

Dimension(L*W*H):

-

As per requirement

-

Weight:

-

45 KG

-

Product name:

-

walking cooler doors hinges torque

-

Inside material:

-

Polyurethane foam

-

Thickness:

-

50/75/100/150mm

-

Surface material:

-

Painted galvanized steel/Stainless steel/Embossing aluminum

-

Net weight:

-

60kg

-

Closer:

-

Hydraulic door closer

-

Door type:

-

Hinged door/Convex door/Sliding door

-

Open Style:

-

Sliding

-

Type:

-

Hinged door/Convex door/Sliding door

Quick Details

-

Temperature:

-

-40℃ ~ +20℃

-

Compressor brand:

-

Copeland, Bitzer, Sanyo

-

Panel Thickness:

-

100mm

-

Cooling Capacity:

-

50ton

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DC

-

Voltage:

-

220V/380V

-

Power:

-

As per requirement

-

Dimension(L*W*H):

-

As per requirement

-

Weight:

-

45 KG

-

Product name:

-

walking cooler doors hinges torque

-

Inside material:

-

Polyurethane foam

-

Thickness:

-

50/75/100/150mm

-

Surface material:

-

Painted galvanized steel/Stainless steel/Embossing aluminum

-

Net weight:

-

60kg

-

Closer:

-

Hydraulic door closer

-

Door type:

-

Hinged door/Convex door/Sliding door

-

Open Style:

-

Sliding

-

Type:

-

Hinged door/Convex door/Sliding door

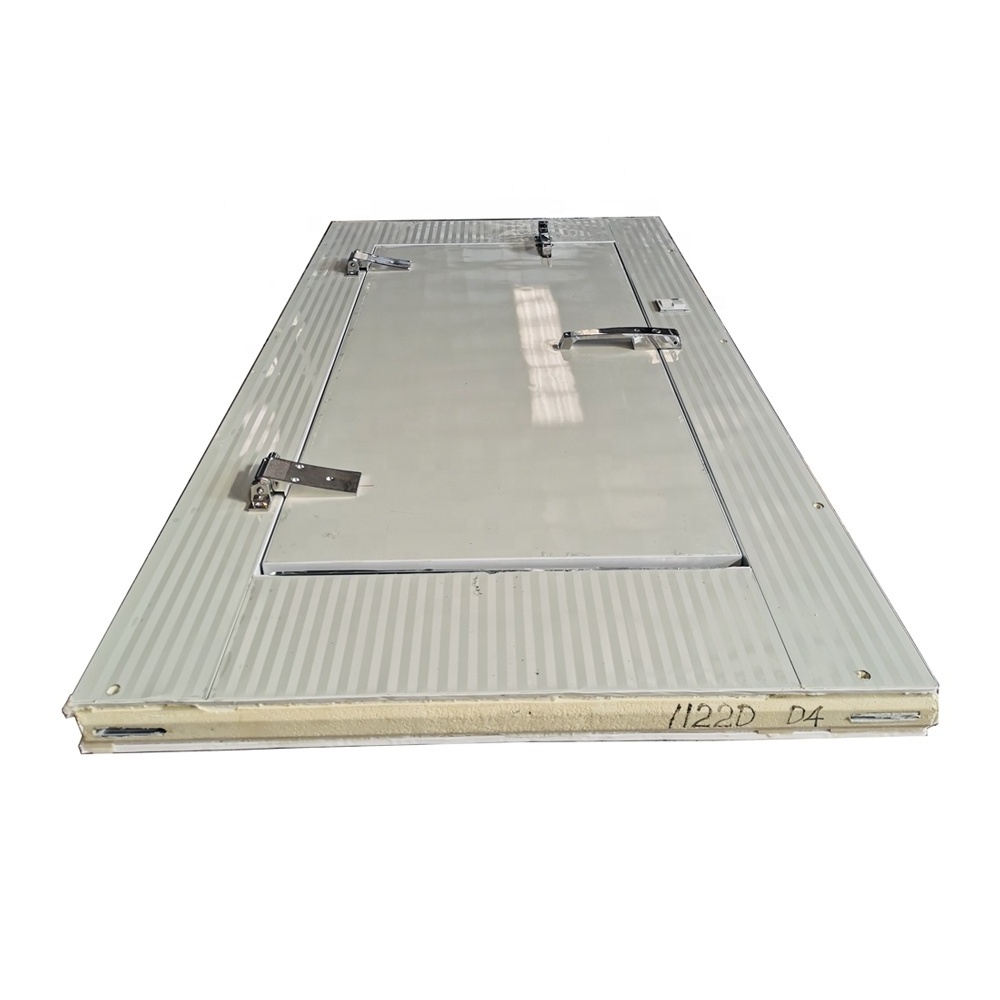

Cold room convex door with painted galvanized steel mat erial

Cold room door feature

1. Inside of the cold room door is made with Bayer polyurethane material by high pressure foaming.The density is up to 43kg/m3 or above.

2. The thickness of panel is 50/75/100/150mm for choice.

3. The

cold room door

is made by heavy duty door hinge,heavy duty door lock and hydraulic door closer.

Cold room door specification

|

Door thickness

|

50,75,100,150mm

|

|||

|

Standard hinged door

|

830x1900H

|

|||

|

|

(Width)

|

(High)

|

(Width)

|

(High)

|

|

Single side door

|

900

|

1800

|

1000

|

1812

|

|

1200

|

2000

|

1300

|

2012

|

|

|

1500

|

2200

|

1600

|

2212

|

|

|

1800

|

2400

|

1900

|

2412

|

|

|

2100

|

2600

|

2200

|

2612

|

|

|

2400

|

2800

|

2500

|

2812

|

|

|

2600

|

3000

|

2700

|

3012

|

|

|

Double side door

|

(Width)

|

(High)

|

(Width)

|

(High)

|

|

1800

|

2500

|

942

|

2512

|

|

|

2400

|

2800

|

1242

|

2812

|

|

|

3000

|

3000

|

1542

|

3012

|

|

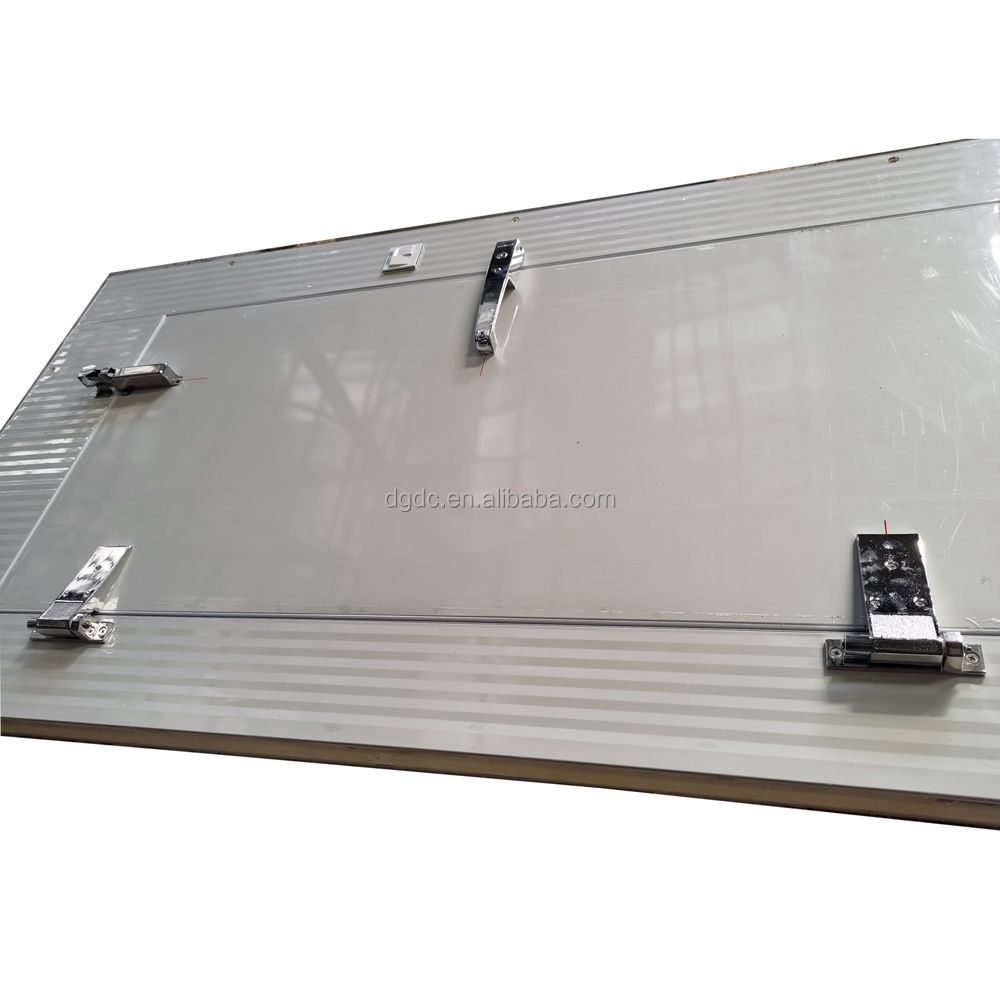

Cold room door introduction

1. Cold room hinged door

1)100% polyurethane insulated under high pressure,high density of 43kg/m3,with fire resistance.

2)Heavy duty door hinges

3)Hydraulic door closer,auto-closing

4)Standard size: 832mm W*1860mm H ( Size can be changed according client's requirement)

5)Door thickness optional: 75mm,100mm,150mm

6)Heater(For defrost) voltage: 24V/36V

7)gasket around to avoid leakness, the cold air is hard to come out and the hot air is hard to come in.

8)Safety handle mounted on the back of the door panel for inside emergency opening.

2. Cold room hinged door

1)100% polyurethane insulated under high pressure,high density of 43kg/m3,with flame resistance.

2)Taiwan hinges

3)Standard size: 800mm W*1900mm H ( Size can be changed according client's requirement)

4)Door thickness optional: 75mm,100mm,150mm

5)Heater(For defrost) voltage: 24V/36V

6)Rubber around to avoid leakness

7)Safety handle mounted on the back of the door panel for inside emergency opening.

3. Cold room Sliding door

1)100% polyurethane insulated under high pressure,high density of 43kg/m3,with flame retardant.

2)Standard size: 832mm W*1860mm H ( Size can be changed according client's requirement)

| Name | Width(mm) | Height(mm) |

| Sliding door | 900 | 1800 |

| Sliding door | 1200 | 2000 |

| Sliding door | 1500 | 2200 |

| Sliding door | 1800 | 2400 |

| Sliding door | 2600 | 2800 |

| Sliding door | 1800 | 2500 |

| Sliding door | 3000 | 3000 |

3)Door thickness optional: 75mm,100mm,150mm

4)Heater(For defrost) voltage: 24V/36V

5)Rubber around to avoid leakness

6)Safety handle mounted on the back of the door panel for inside emergency opening.

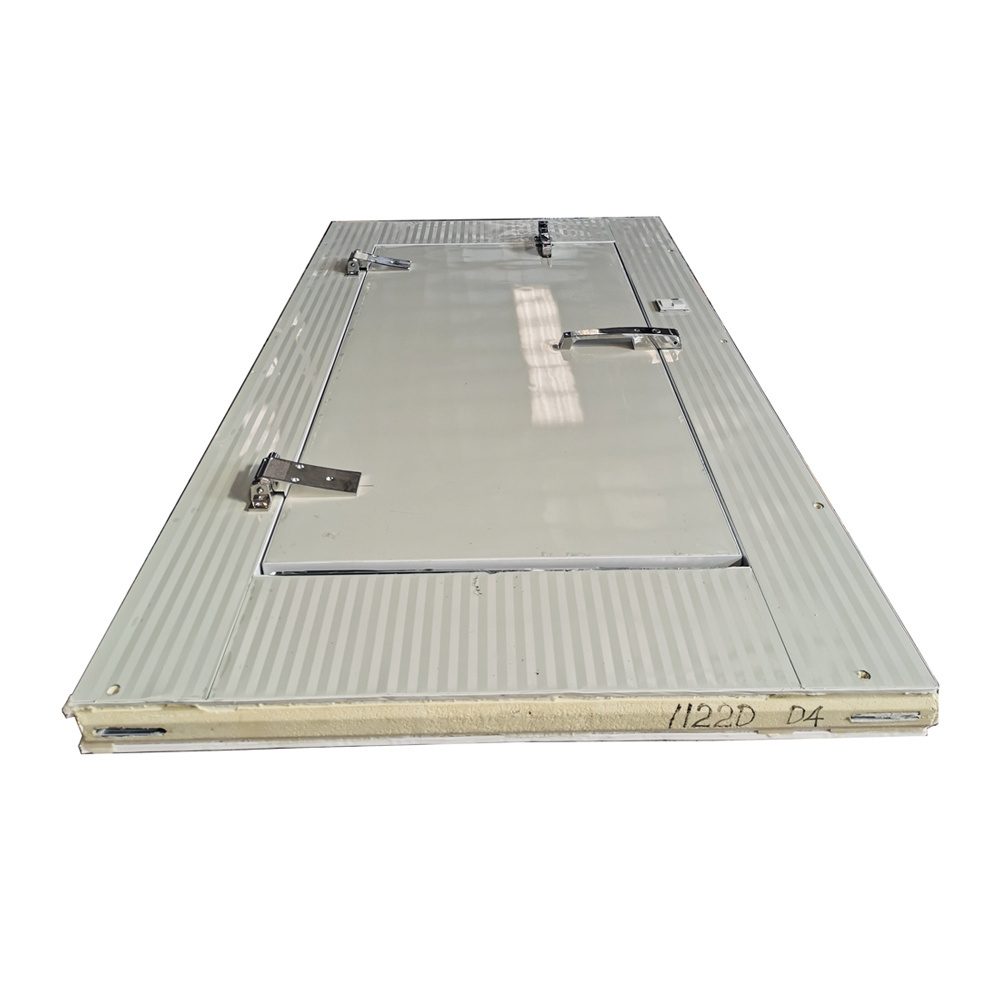

Cold room door package

1. Cold room door is usually packed in bubble paper,convenient,use the possible space of the container,save cost.

2.If sent by LCL,they are firstly wrapped in bubble paper, then put into wooden/plywood case,stronger packing to protect the panels away from damage caused by transportation.