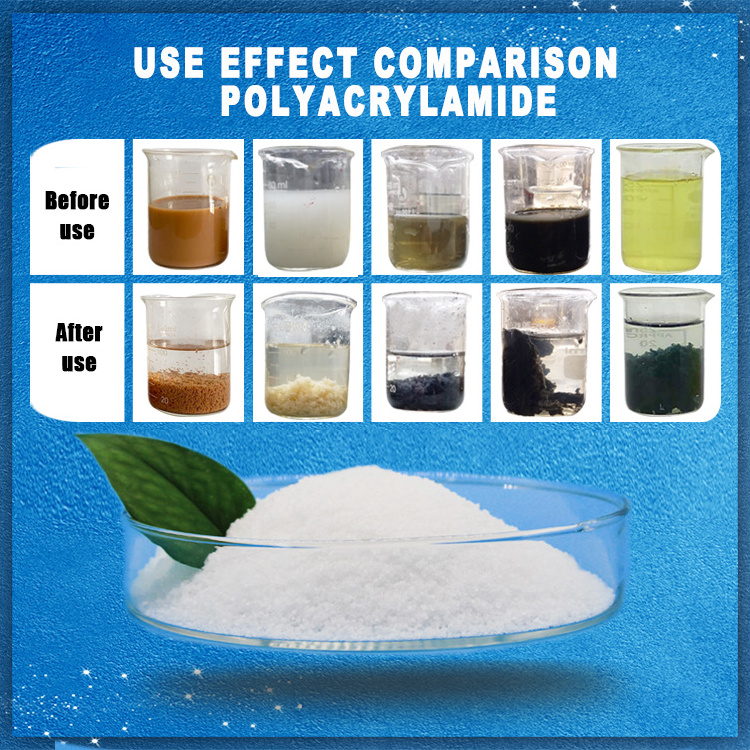

Polyacrylamide, abbreviated as PAM, is a linear polymer which is one of the most widely used varieties of water-soluble polymer compounds. Polyacrylamide and its derivatives can be used as effective flocculants, thickeners, paper enhancers and liquid drag reducers, etc., widely used in water treatment, paper making, petroleum, coal, mining and metallurgy, geology, textile Industrial sectors such as construction. Insoluble in most mailing solvents, it has good flocculation and can reduce the frictional resistance between liquids.

According to the ion characteristics, it can be divided into three types: cationic, anionic and nonionic.

- Product Details

- {{item.text}}

Quick Details

-

MF:

-

[CH2-CH(CONH2)]n

-

EINECS No.:

-

208-750-2

-

Place of Origin:

-

Henan, China

-

Type:

-

floccolant

-

Brand Name:

-

SF

-

Model Number:

-

SF-PAM

-

Application:

-

Water Treatment

-

Appearance:

-

White Granule

-

Grade:

-

Super Grade

-

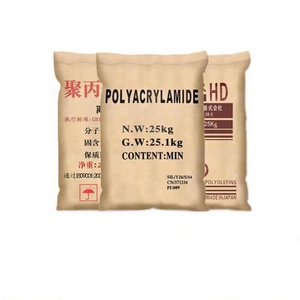

Packing:

-

25kg Kraft Paper Bag

-

MOQ:

-

500kg

-

Shelf life:

-

2 Years

-

PH Value:

-

4.0-9.0

-

Certificate:

-

ISO9001

-

Solid Content:

-

great than or equal to90%

-

Ionization degree:

-

18-22

Quick Details

-

CAS No.:

-

9003-05-8

-

Purity:

-

99.99%

-

Other Names:

-

flocculant

-

MF:

-

[CH2-CH(CONH2)]n

-

EINECS No.:

-

208-750-2

-

Place of Origin:

-

Henan, China

-

Type:

-

floccolant

-

Brand Name:

-

SF

-

Model Number:

-

SF-PAM

-

Application:

-

Water Treatment

-

Appearance:

-

White Granule

-

Grade:

-

Super Grade

-

Packing:

-

25kg Kraft Paper Bag

-

MOQ:

-

500kg

-

Shelf life:

-

2 Years

-

PH Value:

-

4.0-9.0

-

Certificate:

-

ISO9001

-

Solid Content:

-

great than or equal to90%

-

Ionization degree:

-

18-22

Products Description

Water Treatment Polyacrylamide

Cationic Polyacrylamide

Cationic Polyacrylamide is Flocculant. It is a linear polymer dissolved in water. Molecular weights range from 6 million to 12 million. Mainly used for sewage treatment.

Anionic Polyacrylamide

Anionic Polyacrylamide is polymer. It dissolves in water. The molecular weight is about 18 million. It is mainly used to treat

industrial waste water.

industrial waste water.

Nonionic Polyacrylamide

Nonionic Polyacrylamid is a type of Polyacrylamide. The degree of hydrolysis is between 0 and 5. And it is mainly used for oil

well fluid, and acidic waste water treatment.

well fluid, and acidic waste water treatment.

|

Poduct Name

|

Cationic Polyacrylamide

|

Anionic Polyacrylamide

|

Nonionic Polyacrylamide

|

|

|

|

Appearance

|

White Granule

|

White Granule

|

White Granule

|

|

|

|

Ion Degree

|

5%~60%

|

/

|

/

|

|

|

|

Hydrolysis Degree

|

/

|

15%~30%

|

0~5%

|

|

|

|

Solid Content

|

≥90%

|

≥90%

|

≥90%

|

|

|

|

Dissolution Time

|

≤90 minutes

|

≤90 minutes

|

≤90 minutes

|

|

|

Polyacrylamide Application

Application in sewage treatment

Adding polyacrylamide before sludge dewatering can produce larger flocculation mass, which is not easy to disperse during pressure filtration and has high dewatering efficiency.

Application in oil extraction

Polyacrylamide is used as a lubricant, suspending agent, clay stabilizer, oil displacement agent, water loss agent and thickener in drilling, acidification, fracturing, water plugging, cementing and secondary oil recovery, and tertiary oil recovery. Widely

used, it is an extremely important oilfield chemical.

used, it is an extremely important oilfield chemical.

Applied in industrial wastewater purification

In the industrial field, it can be used to treat waste water and circulating water produced by enterprises, and the purified water can be recycled again.

Applied in papermaking

As a retention aid in the paper industry, it can increase the retention rate of fillers and fine fibers; as a filter aid, it can make the slurry flocculate and accelerate the filtration of the wet paper layer in the paper machine mesh.

Usage of Polyacrylamide

1. Polyacrylamide can't be put directly into sewage, so dissolve in water before using Polyacrylamide.

2. The dissolved water should be clean water, and without heating, but the temperature can't be cold. The temperature is higher than five degrees Celsius. Otherwise it will be dissolve very slowly.

2. The dissolved water should be clean water, and without heating, but the temperature can't be cold. The temperature is higher than five degrees Celsius. Otherwise it will be dissolve very slowly.

Temperature above 40 degrees Celsius affect the use effect.

3. Notice: Don't use strong acid, strong base, high salt water preparation.

4. The ratio range is recommended to be between 0.1% and 0.3%. For example, 1 liter of water with 1~3g of agents.

5. If because of other reasons, the dispersion is not good, we suggest that you mix a little more sparse.

6. The water is warmer in Summer. Cationic, Anionic Polyacrylamide should be strict for about 1 hour. Nonionic Polyacrylamide should be strict for about 2 hours.

7. The water is cold in Winter, Cationic, Anionic Polyacrylamide should be strict for about one and a half hours. Nonionic Polyacrylamide should be strict for about 3 hours.

3. Notice: Don't use strong acid, strong base, high salt water preparation.

4. The ratio range is recommended to be between 0.1% and 0.3%. For example, 1 liter of water with 1~3g of agents.

5. If because of other reasons, the dispersion is not good, we suggest that you mix a little more sparse.

6. The water is warmer in Summer. Cationic, Anionic Polyacrylamide should be strict for about 1 hour. Nonionic Polyacrylamide should be strict for about 2 hours.

7. The water is cold in Winter, Cationic, Anionic Polyacrylamide should be strict for about one and a half hours. Nonionic Polyacrylamide should be strict for about 3 hours.

Product packaging

Polyacrylamide is usually packed in 25kg, pp bags or paper plastic composite bags.

Packaging can also be customized according to customer needs.

Hot Searches