- Product Details

- {{item.text}}

Quick Details

-

Size:

-

5",6",8"

-

Width:

-

Hole Diameter: 12.7mm, 25.4mm, 32mm

-

Thickness:

-

Wheel Thickness: 22.23mm, 25.4mm, 28.58mm

-

Grit:

-

#80-1000, #80-1000

-

Place of Origin:

-

Henan

-

Brand Name:

-

RZ

-

Bonding Agent:

-

Electroplated

-

Viscosity:

-

High

-

Product name:

-

band saw grinding wheel

-

Usage:

-

cbn grinding wheel

-

Material:

-

CBN,Cubic Boron Nitride

-

Bond:

-

electroplated

-

Applying machines:

-

wood bandsaw blades sharpener

-

Applicable machine brand:

-

Wright, Vollmer, WM, ABM, Colonial Saw, Armstrong, Amada

-

Applicable grinder:

-

WOODLAND MILLS, WESTRON, MVM, Holzmann, NEVA

-

MOQ:

-

1PCS

Quick Details

-

Application:

-

Aluminum

-

Shape:

-

Flat-Shaped

-

Hardness:

-

High

-

Size:

-

5",6",8"

-

Width:

-

Hole Diameter: 12.7mm, 25.4mm, 32mm

-

Thickness:

-

Wheel Thickness: 22.23mm, 25.4mm, 28.58mm

-

Grit:

-

#80-1000, #80-1000

-

Place of Origin:

-

Henan

-

Brand Name:

-

RZ

-

Bonding Agent:

-

Electroplated

-

Viscosity:

-

High

-

Product name:

-

band saw grinding wheel

-

Usage:

-

cbn grinding wheel

-

Material:

-

CBN,Cubic Boron Nitride

-

Bond:

-

electroplated

-

Applying machines:

-

wood bandsaw blades sharpener

-

Applicable machine brand:

-

Wright, Vollmer, WM, ABM, Colonial Saw, Armstrong, Amada

-

Applicable grinder:

-

WOODLAND MILLS, WESTRON, MVM, Holzmann, NEVA

-

MOQ:

-

1PCS

Products Description

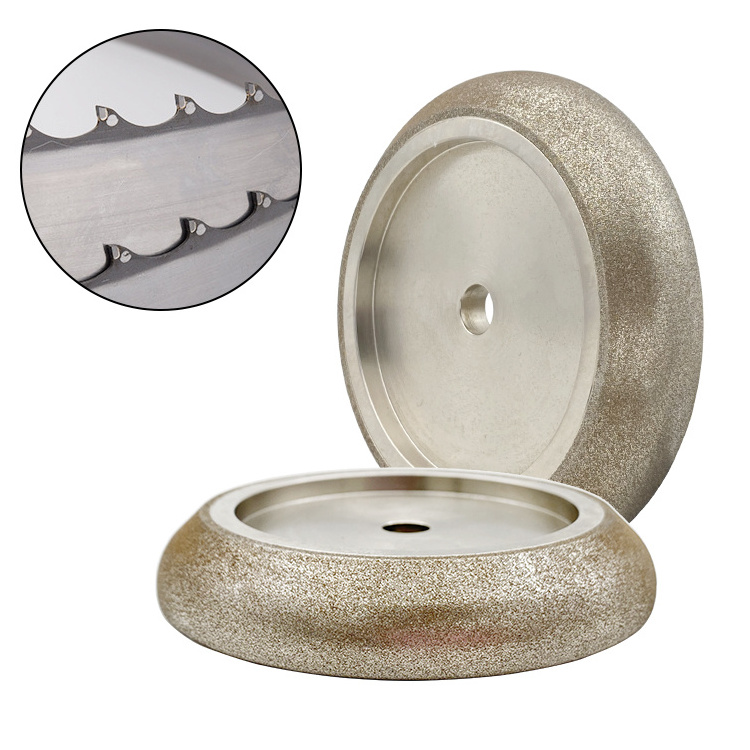

Sharpening sawmill bandsaw blades angle Electroplated CBN grinding Wheel disc WM diamond stone

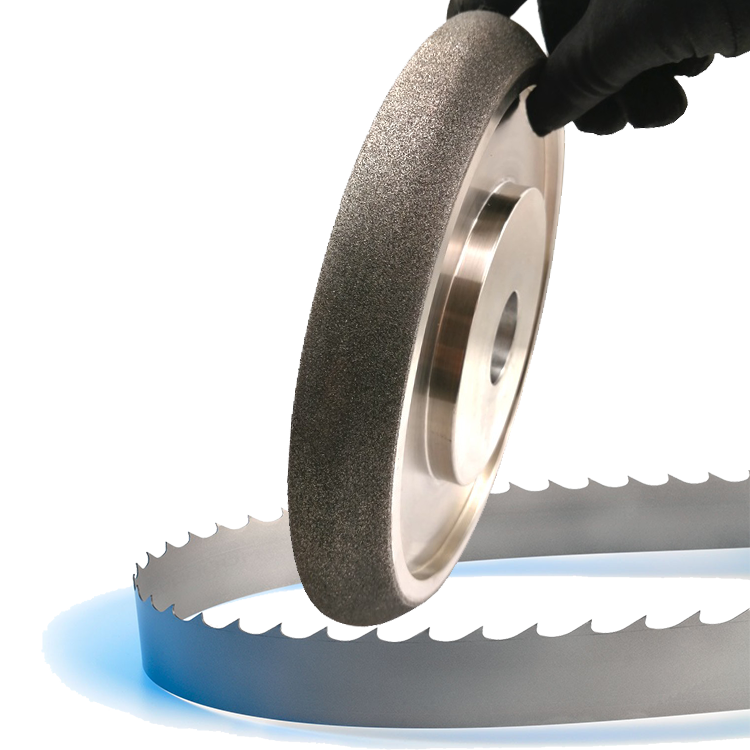

Electroplated CBN band saw sharpening wheel is coated with CBN(Cubic Boron Nitride) on steel body,specially for band saw sharpening of any type. Electroplated CBN Grinding Wheels are used for bandsaw sharpening. Electroplated cbn band saw sharpening wheel achieves superior performance, gives high quality finish. They are produced with steel core and electroplated (nickel bonded) rim. Lasts very long. Reduces band saw breaking. No need no profile, no dust. These wheels are perfect choice to grind band saws.

Product Features.

1. Quickly grind band saw blades with precise contours and excellent finish

2. Longer life than traditional grinding wheels

3. Cost-effective: unit cost is much lower.

4. No contour loss during the grinding process, no need for trimming

5. The wheel core can be recycled and reused to reduce waste

2. Longer life than traditional grinding wheels

3. Cost-effective: unit cost is much lower.

4. No contour loss during the grinding process, no need for trimming

5. The wheel core can be recycled and reused to reduce waste

Application

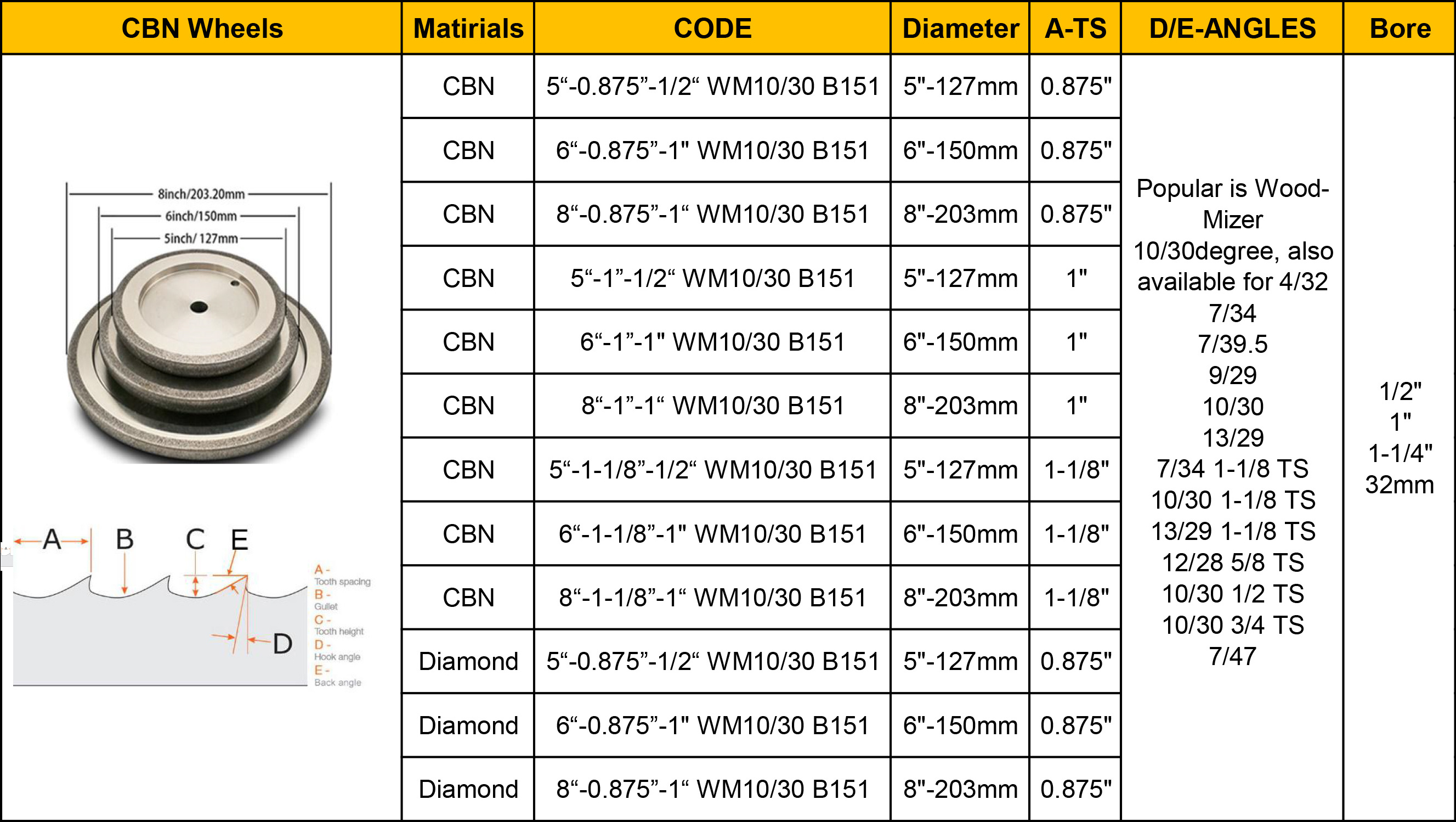

Applicable machine brand:

Wright, Vollmer, WM, Colonial Saw, Amada, Cooks, WOODLAND MILLS, TimberKing, WESTRON, MVM, Holzmann, NEVA, ISELI, Hud-Son, ZMJ, YOKEN.

Saw blade applicable: Simonds, Lenox, Wood-Mizer, Dakin-Flathers Ripper, Timber Wolf, Lenox Woodmaster, Munkfors, Fenes, Armoth, Ro-Ma, Wintersteiger, MK Morse, Forezienne, Bacho, Pilana, Disston, Ellis, Norwood.

Saw blade applicable: Simonds, Lenox, Wood-Mizer, Dakin-Flathers Ripper, Timber Wolf, Lenox Woodmaster, Munkfors, Fenes, Armoth, Ro-Ma, Wintersteiger, MK Morse, Forezienne, Bacho, Pilana, Disston, Ellis, Norwood.

Selection of grinding wheel elements.

1.hard grinding material, choose the soft, fine grit grinding wheel. Soft grinding material, should choose a hard, coarse grit grinding wheel. By doing this ,grinding wheel loss is small, also not easy to plug.

2. when doing the rough grinding ,in order to increase the productivity, the coarse grit, soft grinding wheel should be chosen,In order to improve the surface quality of the work piece during accurate grinding , the fine grit ,hard grinding wheel should be chosen.

3.the large area of grinding or thin-walled work piece grinding should choose the coarse grit, soft grinding wheel. This wheel is not easy to plug, the surface of the work piece is not easy to burn, the work piece is not easy to deformation.

4. form grinding process to select the fine grit, the small organization, and the hard grinding wheel to maintain the profile of the grinding wheel.

2. when doing the rough grinding ,in order to increase the productivity, the coarse grit, soft grinding wheel should be chosen,In order to improve the surface quality of the work piece during accurate grinding , the fine grit ,hard grinding wheel should be chosen.

3.the large area of grinding or thin-walled work piece grinding should choose the coarse grit, soft grinding wheel. This wheel is not easy to plug, the surface of the work piece is not easy to burn, the work piece is not easy to deformation.

4. form grinding process to select the fine grit, the small organization, and the hard grinding wheel to maintain the profile of the grinding wheel.

Related Products

Why Choose Us

International Leading Trade Fair

for Grinding Technology

Hot Searches