- Product Details

- {{item.text}}

Quick Details

-

Application:

-

aquaculture, Aquaculture Landfill

-

Design Style:

-

Industrial

-

Place of Origin:

-

SHN

-

Brand Name:

-

OBOR

-

Model Number:

-

HDPE

-

Product Name:

-

HDPE Geomembrane

-

Material:

-

100% Vigrin HDPE

-

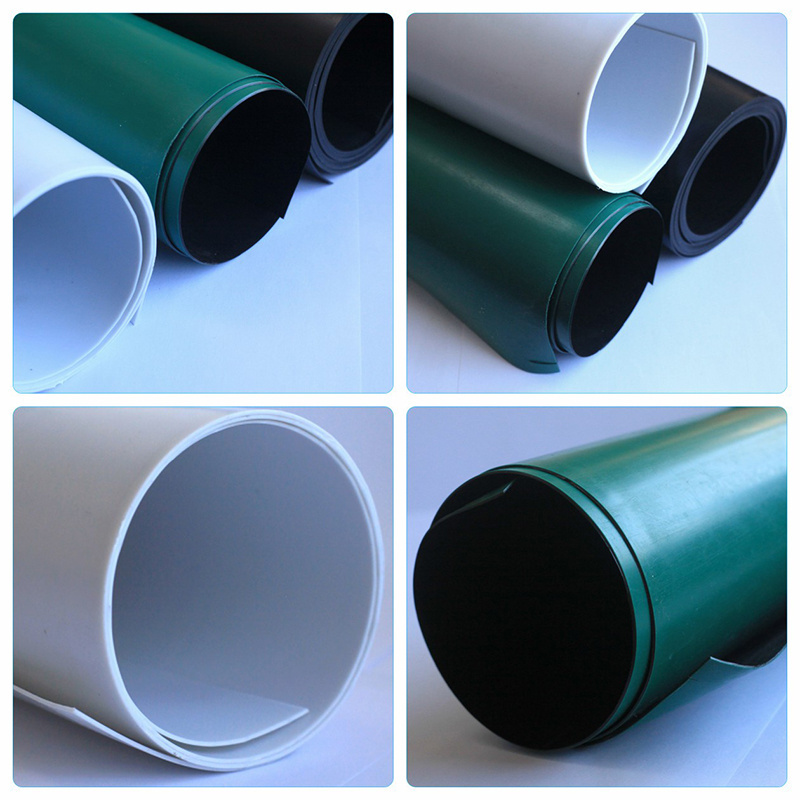

Color:

-

Black White Blue Green (customized)

-

Keyword:

-

Geomembrane 1.5mm Geomembrane Liner Smooth Hdpe Geomembrane

-

Thickness:

-

0.1mm,0.2mm,0.5mm,0.75mm,1.0mm,1.5mm,2.0mm,3.0mm

-

Length:

-

50m-200m/roll (as Request)

-

Width:

-

1m,2m,3m,4m,5m,6m,7m,8m,10m,12m

-

Surface:

-

Double Smooth

-

Standard:

-

ASTM GRI-GM13

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

aquaculture, Aquaculture Landfill

-

Design Style:

-

Industrial

-

Place of Origin:

-

SHN

-

Brand Name:

-

OBOR

-

Model Number:

-

HDPE

-

Product Name:

-

HDPE Geomembrane

-

Material:

-

100% Vigrin HDPE

-

Color:

-

Black White Blue Green (customized)

-

Keyword:

-

Geomembrane 1.5mm Geomembrane Liner Smooth Hdpe Geomembrane

-

Thickness:

-

0.1mm,0.2mm,0.5mm,0.75mm,1.0mm,1.5mm,2.0mm,3.0mm

-

Length:

-

50m-200m/roll (as Request)

-

Width:

-

1m,2m,3m,4m,5m,6m,7m,8m,10m,12m

-

Surface:

-

Double Smooth

-

Standard:

-

ASTM GRI-GM13

Product Description

High Density Poly Ethylene, HDPE High Density Polyethylene

Broad chemical resistance. Excellent UV resistance. Good weld strength. Good low temperature properties. Good mechanical properties. Relatively inexpensive. HDPE has a wide spectrum of applications from pond lining, dam lining to waste containment in landfill applications, secondary containment (fuel farms), water storages, tailings dams, evaporation ponds, brine ponds.

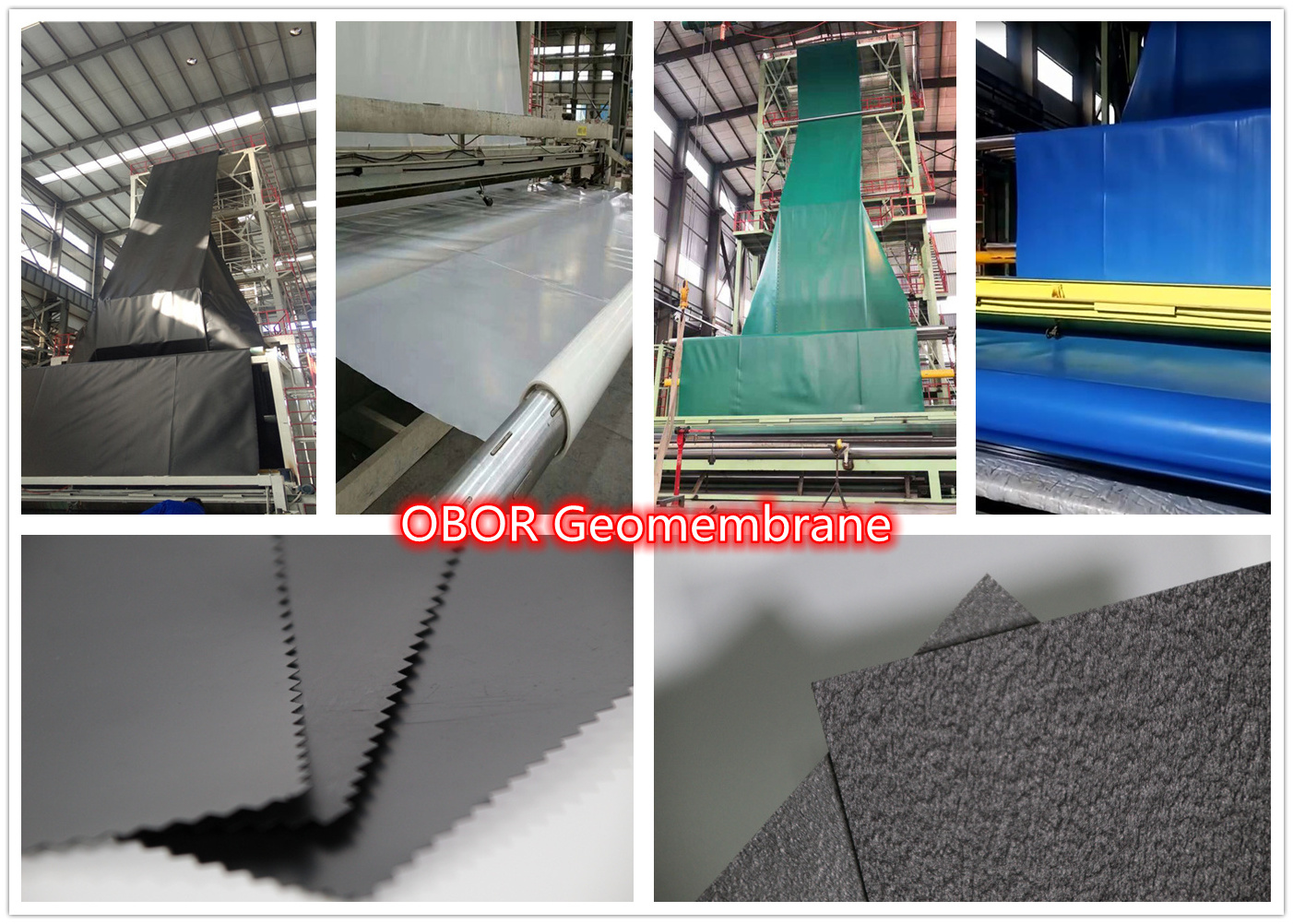

OBOR HDPE Geomembranes are manufactured with High Density Polyethylene (PEAD or HDPE) resins of the highest quality and performance, which have been duly verified and meet the strictest requirements for the application to which they are intended .destined. HDPE Geomembranes stand out for their durability and resistance to safely contain from water to any type of potentially toxic or polluting waste for the environment, whether solid, liquid, urban, industrial, mining, hazardous or non-hazardous.

OBOR HDPE Geomembranes are manufactured with High Density Polyethylene (PEAD or HDPE) resins of the highest quality and performance, which have been duly verified and meet the strictest requirements for the application to which they are intended .destined. HDPE Geomembranes stand out for their durability and resistance to safely contain from water to any type of potentially toxic or polluting waste for the environment, whether solid, liquid, urban, industrial, mining, hazardous or non-hazardous.

Features:

1 Excellent chemical resistance;

2 outstanding resistance to stress cracking;

3 lowest permeability;

4 Excellent UV resistance;

5 Stable anti-aging properties, high temperature and low temperature resistance

2 outstanding resistance to stress cracking;

3 lowest permeability;

4 Excellent UV resistance;

5 Stable anti-aging properties, high temperature and low temperature resistance

Specification

|

item

|

value

|

|

Type

|

Geomembranes

|

|

Warranty

|

More than 5 years

|

|

After-sale Service

|

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

|

|

Project Solution Capability

|

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

|

|

Application

|

aquaculture

|

|

Design Style

|

Industrial

|

|

Place of Origin

|

SHN

|

|

Brand Name

|

OBOR

|

|

Model Number

|

HDPE

|

|

Application

|

Landfill

|

|

Product Name

|

HDPE Geomembrane

|

|

Material

|

100% Vigrin HDPE

|

|

Color

|

Black White Blue Green (customized)

|

|

Keyword

|

Geomembrane 1.5mm Geomembrane Liner Smooth Hdpe Geomembrane

|

|

Thickness

|

0.1mm,0.2mm,0.3mm,0.5mm,0.75mm,1.0mm,1.5mm,2.0mm,3.0mm

|

|

Length

|

50m-200m/roll (as Request)

|

|

Width

|

1m-12m

|

|

Surface

|

Double Smooth

|

|

Standard

|

ASTM GRI-GM13

|

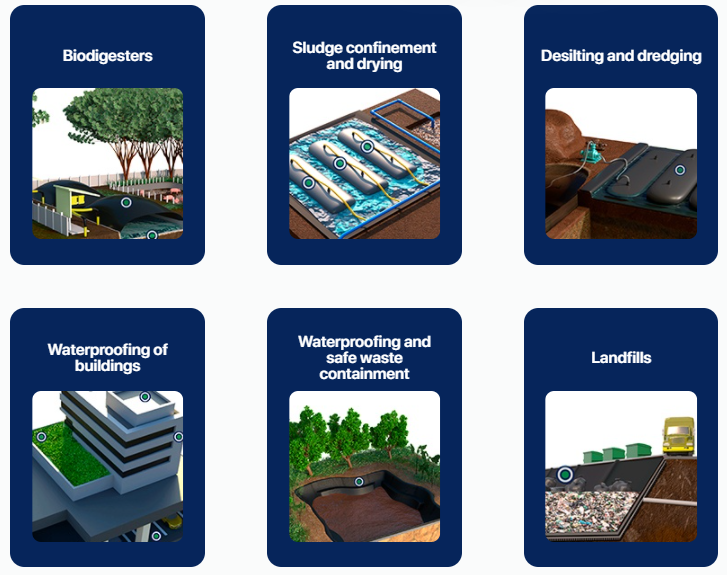

Applications can include:

(1) Environmental protection and sanitation projects (such as domestic waste landfills,

sewage treatment plants, workshops)

(2) Water conservancy and civil engineering (river/lake/reservoir/dike anti-seepage, plugging, reinforcement)

(3) Municipal engineering (underground, underground construction of buildings and roof tanks, lining of sewage pipes)

(4) Landscaping (artificial lake, pond, pond lining of golf course)

(5) Petrochemical (chemical plant, oil refinery storage tank anti-seepage and anti-fouling, chemical reaction tank lining)

(6) Mining (washing pond, heap leaching pond, ash dump)

(7) Traffic engineering (highway foundation reinforcement, culvert seepage prevention)

(8) Agriculture (reservoir, reference basin, storage tank, anti-seepage of irrigation system)

(9) Aquaculture (lining of fish ponds, shrimp ponds)

(10) Polluting enterprises (phosphorite enterprises, sugar factories)

sewage treatment plants, workshops)

(2) Water conservancy and civil engineering (river/lake/reservoir/dike anti-seepage, plugging, reinforcement)

(3) Municipal engineering (underground, underground construction of buildings and roof tanks, lining of sewage pipes)

(4) Landscaping (artificial lake, pond, pond lining of golf course)

(5) Petrochemical (chemical plant, oil refinery storage tank anti-seepage and anti-fouling, chemical reaction tank lining)

(6) Mining (washing pond, heap leaching pond, ash dump)

(7) Traffic engineering (highway foundation reinforcement, culvert seepage prevention)

(8) Agriculture (reservoir, reference basin, storage tank, anti-seepage of irrigation system)

(9) Aquaculture (lining of fish ponds, shrimp ponds)

(10) Polluting enterprises (phosphorite enterprises, sugar factories)

LANDFILL LINING

Landfill uses various types of Geosynthetic products to ensure the integrity of the landfill system. For environmental protection,

it is essential the waterproof Geomembrane liner be the barrier layer on the floor and sides of a containment facility.

To protect the valuable underground water resources landfill needs to deploy more than a smooth surfaced HDPE Geomembrane. Steep slopes become desirable for landfill to increase the capacity and diversify the location selects. Smooth liners have problems to make the top soil stay in place so OBOR provides co-extruded textured geomembrane for lining steep slopes.

OBOR textured HDPE Geomembrane is made up of unique co-extrusion textured finishes to utilize the fiction advantage for lining slopes. OBOR textured HDPE can provide outstanding friction between OBOR textured and all kinds of Geocomposite(Geotextile) and the top soil.

LANDFILL CAPS

Capping is the barrier layer on top of a solid waste containment facility that forms a barrier between the contaminated media and the surface, thereby shielding humans and the environment from the harmful effects of its contents. A cap must restrict surface water (rain) infiltration into the contaminated subsurface to reduce the contaminants leaching from the site.

OBOR LLDPE geomembrane is made from premium Linear Low Density Polyethylene (LLDPE) resin. Its advantage is to provide excellent flexibility and elongation for the deformation when the waste is settled by decaying in the landfill.

LEACHATE PONDS

Leachate is collected from operating landfill and stored in ponds for wastewater treatment and evaporation. To protect the

groundwater HDPE Geomembrane lining system is indispensable to be the primary containment barrier.

OBOR HDPE Geomembrane featuring the excellent chemical resistance, superior impermeability, high tearing and puncture resistance and tensile strength is the most durable and reliable material for leachate ponds.

Landfill uses various types of Geosynthetic products to ensure the integrity of the landfill system. For environmental protection,

it is essential the waterproof Geomembrane liner be the barrier layer on the floor and sides of a containment facility.

To protect the valuable underground water resources landfill needs to deploy more than a smooth surfaced HDPE Geomembrane. Steep slopes become desirable for landfill to increase the capacity and diversify the location selects. Smooth liners have problems to make the top soil stay in place so OBOR provides co-extruded textured geomembrane for lining steep slopes.

OBOR textured HDPE Geomembrane is made up of unique co-extrusion textured finishes to utilize the fiction advantage for lining slopes. OBOR textured HDPE can provide outstanding friction between OBOR textured and all kinds of Geocomposite(Geotextile) and the top soil.

LANDFILL CAPS

Capping is the barrier layer on top of a solid waste containment facility that forms a barrier between the contaminated media and the surface, thereby shielding humans and the environment from the harmful effects of its contents. A cap must restrict surface water (rain) infiltration into the contaminated subsurface to reduce the contaminants leaching from the site.

OBOR LLDPE geomembrane is made from premium Linear Low Density Polyethylene (LLDPE) resin. Its advantage is to provide excellent flexibility and elongation for the deformation when the waste is settled by decaying in the landfill.

LEACHATE PONDS

Leachate is collected from operating landfill and stored in ponds for wastewater treatment and evaporation. To protect the

groundwater HDPE Geomembrane lining system is indispensable to be the primary containment barrier.

OBOR HDPE Geomembrane featuring the excellent chemical resistance, superior impermeability, high tearing and puncture resistance and tensile strength is the most durable and reliable material for leachate ponds.

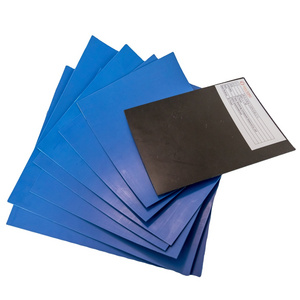

Packing & Delivery

1. Packing:

PP woven geotextile bags or PE film. Or according to customers requirements.

2.Delivery:

Within 7-10 days after receiving your deposit. Samples are for your review.

The geomembrane roll are in the hand sewing woven bag packing,safe and scratch-proof.The bag color can be customized,with your own logo.

PP woven geotextile bags or PE film. Or according to customers requirements.

2.Delivery:

Within 7-10 days after receiving your deposit. Samples are for your review.

The geomembrane roll are in the hand sewing woven bag packing,safe and scratch-proof.The bag color can be customized,with your own logo.

1 Geomembrane construction technology

Laying, cutting → aligning, aligning → laminating and shaping → wiping dust → welding test → welding → testing → repairing → re-inspection → acceptance

2. Technical points

(1) Minimize the amount of splicing when laying, so as to achieve a satisfactory anti-seepage effect under unfavorable conditions.

(2) When laying geomembrane, it should start from the lowest position and extend to the high position. Don't pull too tight, and leave enough margin (about 1.5%) to prepare for local sinking and stretching.

(3) When laying the slope, according to the actual situation of the project, it can be determined to be laid parallel or perpendicular to the maximum slope line based on the principle of least joints, easy construction, and reasonable cutting. Seams should be avoided

Open corners, set at the plane. Where the slope is relatively large, a soft ladder is set up, and the construction personnel carry out the welding joint construction of the geomembrane on the soft ladder.

(4) During the laying process, welds, especially cross welds, should be minimized to reduce leakage hazards. During the film unfolding process, it is forbidden to pull the geomembrane forcefully, and it is not allowed to press out the dead fold. When the weld is welded, the floating soil on it must be wiped clean, otherwise the upper and lower membranes cannot be heat-sealed together. To connect with the building foundation, the geomembrane must be flattened and not folded, so as to provide good operating conditions for edge sealing.

(5) According to the design direction of film laying, use a heat welding machine to weld. Before the formal welding, test welding is carried out first, and then large-area welding construction is carried out. When welding, prevent the welding machine from being blocked and leaking the geomembrane and affecting the welding speed and quality.

(6) The lap width should meet the design requirements, and the double-pass welding seam method is adopted to provide multiple protections, and the welding effect can be tested by inflating between the welding layers. After welding, the welding quality of the weld should be checked in time.

(7) When T-shaped seams and double T-shaped seams appear, the base material is used to fill the scar, and the corners of the scar are rounded. The seam of the geomembrane is the key to construction quality control, and it should be strictly monitored during welding. The expansion or contraction of the geomembrane affected by the temperature will cause difficulties in splicing. Adjust the temperature and speed to prevent the seam from bending, overlapping, weak welding or ironing through the seam.

Hot Searches