- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ

-

Power:

-

9kw

-

Dimension(L*W*H):

-

1600*1100*1750mm

-

Weight (KG):

-

800

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Model:

-

LTTPG-5

-

Evaporation Capacity:

-

5KG/h

-

Material Consist:

-

SS304(SS316 is available)

-

Working Principle:

-

powder mixed with spay granulate and dry

-

Control System:

-

PLC control or Micro computer

-

Safety Protector:

-

available

-

Inlet temperature:

-

140-350 ℃( Automatically controlled)

-

Weight:

-

1000kg

Quick Details

-

Type:

-

Spray Drying Equipment

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LTPM China

-

Voltage:

-

380V/50HZ

-

Power:

-

9kw

-

Dimension(L*W*H):

-

1600*1100*1750mm

-

Weight (KG):

-

800

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Model:

-

LTTPG-5

-

Evaporation Capacity:

-

5KG/h

-

Material Consist:

-

SS304(SS316 is available)

-

Working Principle:

-

powder mixed with spay granulate and dry

-

Control System:

-

PLC control or Micro computer

-

Safety Protector:

-

available

-

Inlet temperature:

-

140-350 ℃( Automatically controlled)

-

Weight:

-

1000kg

Product Description:

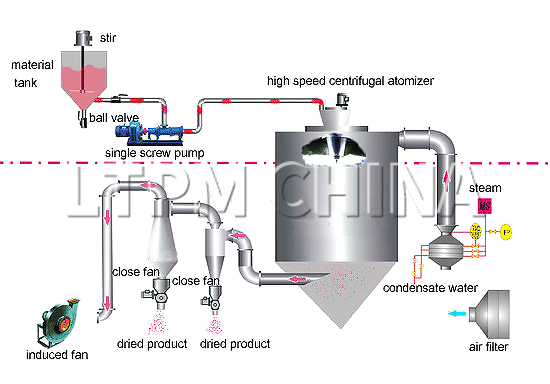

Spray drying is the widest used technology in the liquid shaping technology and in the drying industry. Centrifugal Atomizing (Spray) Drying Equipment is most suitable for producing powder, particles or solid block products from materials of solution, emulsion, soliquoid and pumpable paste states. Therefore, spray drying is useful to create the desired particle size, residual water contents, the stocking density, and the particle shape needed to meet precise standards.

Manufacturing and Applications

The air is through the filter and heater, the air distributor which enters the dedicator top, the hot air takes the form of spiral and enters the dedicator evenly. The material liquid , from the material liquid trough from the at odds with the community or the leadership atomizer for the dedicator top of pump sending through the filter, make the material liquid gush out into an extremely small calorific drop, material liquid and hot air flow and keep in touch, moisture evaporate rapidly, within extremely short time dry to become finished product, finished product discharge by dry tower bottom and whirlwind separator, the waste gas is discharged by the air blower.

Alumina Powder

Herbal Powder

Egg Powder

Milk Powder

Soy Sauce Powder

Polyphenols

Features

1

.High speed drying. 95%-98% of moisture will be evaporated in high temperature airflow in a flash, only needs seconds time.

2

.Adopts Single position spray drying to make the liquid drop and hot air running in same position. This is machine is also fit for the materials which are sensitive with Heating.

3

.Because the drying is processed in a flash, so the finished product is Ball Shape with good mobility and good solubility.

4

.The machine is Simple production with easy operation control system used for drying 50-80% moisture contained materials, even some special material with 90% moisture contained can be dried in a flash to powder.

5

.All contact parts are made in SS304.

Technical Data

|

Model

|

5

|

25

|

50

|

100

|

150

|

200-2000

|

|||||

|

Inlet temperature

|

140-350°C(automatic control)

|

|

|

|

|

|

|||||

|

Outlet temperature

|

80-90°C

|

|

|

|

|

|

|||||

|

Max. evaporation(kg/h)

|

5

|

25

|

50

|

100

|

150

|

200-2000

|

|||||

|

Centrifugal spraying nozzle transmission mode

|

compressed air transmission

|

mechanical transmission

|

|

|

|

|

|||||

|

Rotation speed (r.p.m)

|

25000

|

22000

|

21500

|

18000

|

18000

|

15000

|

|||||

|

Spray disc diameter

|

50mm

|

100mm

|

120mm

|

140mm

|

150mm

|

180-340mm

|

|||||

|

thermal source

|

electricity

|

electricity

|

electricity + steam, fuel, oil, fuelgas

|

|

|

solved by user

|

|||||

|

Max. electric heating power (kw)

|

8

|

31.5

|

60

|

81

|

99

|

|

|||||

|

Overall dimension

|

1.8*0.93*2.2

|

3*2.7*4.26

|

3.7*3.2*5.1

|

4.6*4.2*6

|

5.5*4.5*7

|

optional

|

|||||

|

Powder recollection (%)

|

95

|

95

|

95

|

95

|

95

|

95

|

|||||

Product Details

Hot Searches