- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

100kw

-

Dimension(L*W*H):

-

2800*1400*1700mm

-

Weight:

-

1500kg

-

Warranty:

-

12 months

-

Product name:

-

Disposable Pulp Molding Takeaway box Making Machine

-

Raw material:

-

sugarcane, bamboo, bagasse, fibre

-

Finished Products:

-

paper plate/lunch box/takeout box

-

Application:

-

paper plate

-

Production:

-

Paper products machine

-

Capacity:

-

600pcs-1000pcs per day

-

Color:

-

Customized Color

-

Type:

-

Packaging Line

-

Name:

-

Pulp moulded Machine

-

finished products:

-

paper plate

Quick Details

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

ZH brand

-

Model Number:

-

multilayer drying line

-

Voltage:

-

380V

-

Power:

-

100kw

-

Dimension(L*W*H):

-

2800*1400*1700mm

-

Weight:

-

1500kg

-

Warranty:

-

12 months

-

Product name:

-

Disposable Pulp Molding Takeaway box Making Machine

-

Raw material:

-

sugarcane, bamboo, bagasse, fibre

-

Finished Products:

-

paper plate/lunch box/takeout box

-

Application:

-

paper plate

-

Production:

-

Paper products machine

-

Capacity:

-

600pcs-1000pcs per day

-

Color:

-

Customized Color

-

Type:

-

Packaging Line

-

Name:

-

Pulp moulded Machine

-

finished products:

-

paper plate

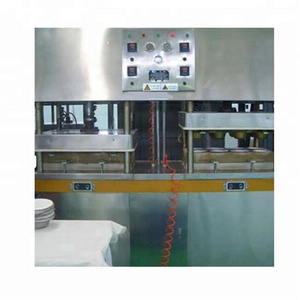

Disposable Pulp Molding Takeaway box Making Machine

| Mode type | TS-6650 | TS-8270 | TS-1350 |

| Platen size | 660*500mm | 820*700mm | 1350*1350mm |

| Capacity based on 5" | 1440~1800/hr | ||

| Capacity based on 8" | 600~700/hr | 1100~1350/hr | 1875-2250/hr |

| Capacity based on 10" | 720~800/hr | 200~1440pcs/hr |

Introduction of the pulp molded Machine

The top-end Molded pulp production line process: pulping, screening and refining process. The pulp will be adjusted to a certain consistency, and then it will be formed on the mold of the forming machine by vacuum suction. The final molded pulp tableware can be produced after drying, pressing, trimming and die-cutting.

The Bagasse Pulp Molded pulp tableware machine line has high requirement on the output, hygiene and surface finishing, so the molded pulp tableware machines that ZH developed are with large platen size, fully automatic control, high precision platen machining, high precision mold processing and interlligent temperature control. With all these features, molded pulp tableware machine improved by ZH drastically the production efficiency, safety and product quality, with lower labor cost.

The machine line mainly produces tableware plate products, and other higher quality demanded of both smooth side of packages products, like electrical inner packages, elegant mask,etc. It is for high demand of packages products machine line, which the process of drying, hot-pressing, forming will be automatic continuous completed on the same machine,with high automatic of PLC+ Touch screen control whole process.

<span

The Advantages of Paper Pulp Molding Production Line

1. Waste paper Recycling with low cost

Its raw material are any kind of papers, like wasted newspaper, carton, printers or leftover bits in paper mill, convenient to collect with low cost. The cost of pulp molding product is much lower than EPS products.

2. Best environmental protection:

non-environmental pullution during the whole process of production, utility and waste treatment: no waste water consumption with water recycling, no waste materials with waste paper recycling, and non-environmental pullution.

3. Recycling use

low recycling cost and it can be used repeatedly. Biodegradable as vegetable fiber during one or two month. The finished products can be stacked, space-saving.

4. Good Market prospect

There is a restriction in developed country such as Europe, America ans Japan for importing EPS products, and advocate the use of enviromental packaging materials, encourage for Eco-package replaced of EPS packages in order to reject white pollution.

5. Good Performance.

Anti-shack, anti-static electricity, better efficiency than EPS, PS and PVC products.