- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

600 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MAIWEI

-

Year:

-

New

-

Voltage:

-

Acoording customer country

-

Dimension(L*W*H):

-

customize

-

Clamping Force (kN):

-

40000

-

Weight (KG):

-

3000 KG

-

Product name:

-

Blow moulding machine

-

Certification:

-

ISO CE

-

After-sales Service Provided:

-

Online Service Provided

-

Suitable bottle:

-

Drink Bottle

-

Bottle material:

-

PET PP

-

Machine type:

-

Stretch Bottle Blowing

-

Key words:

-

Bottle Making Machine

-

Customer's requipment:

-

Customized Designed

-

Advantages:

-

High Efficiency

-

Function:

-

Auto Blow Molding Machine

Quick Details

-

Neck Diameter(mm):

-

68 mm

-

Max.Bottle Diameter(mm):

-

100 mm

-

Max.Bottle Height(mm):

-

260 mm

-

Bottle Volume(ml):

-

600 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MAIWEI

-

Year:

-

New

-

Voltage:

-

Acoording customer country

-

Dimension(L*W*H):

-

customize

-

Clamping Force (kN):

-

40000

-

Weight (KG):

-

3000 KG

-

Product name:

-

Blow moulding machine

-

Certification:

-

ISO CE

-

After-sales Service Provided:

-

Online Service Provided

-

Suitable bottle:

-

Drink Bottle

-

Bottle material:

-

PET PP

-

Machine type:

-

Stretch Bottle Blowing

-

Key words:

-

Bottle Making Machine

-

Customer's requipment:

-

Customized Designed

-

Advantages:

-

High Efficiency

-

Function:

-

Auto Blow Molding Machine

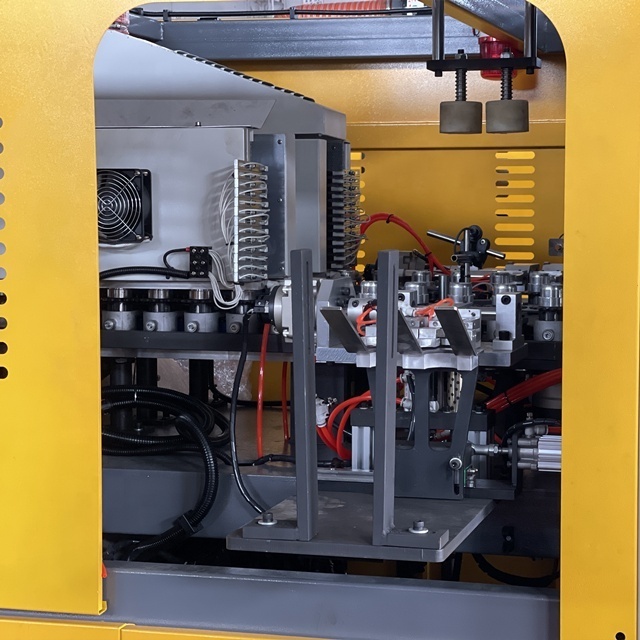

Products Description

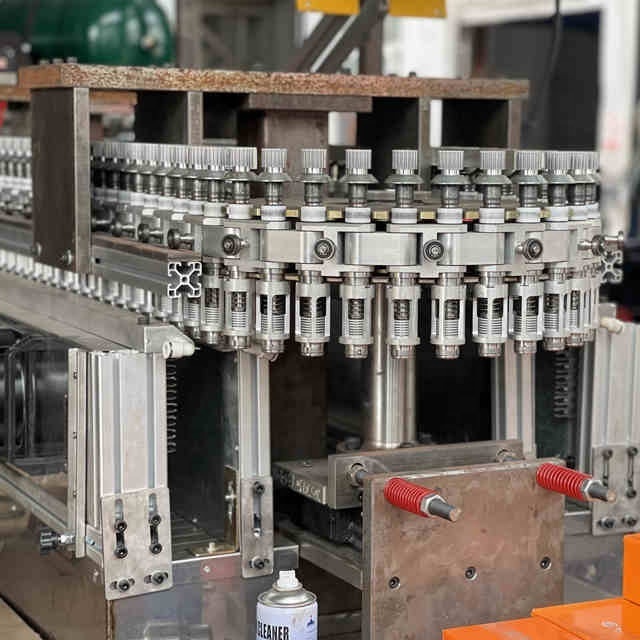

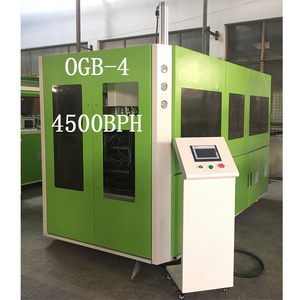

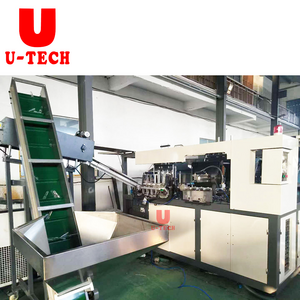

1.Brief Introduction

MW 4-cavity automatic stretch blow molding machine can produce all kinds of bottles below 1800ml, including soda and mineral water bottles, fruit juice bottles, food packaging bottles, edible oil bottles, wine bottles, cosmetic bottles, etc.

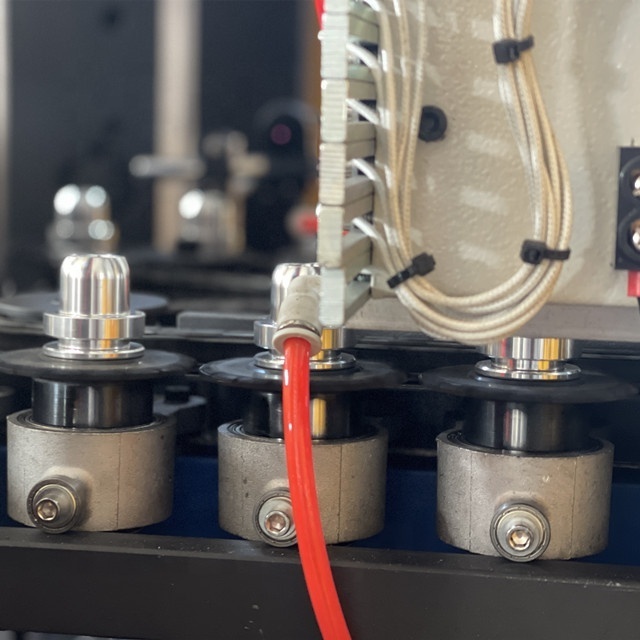

2.Features and Advantages

* Heating tubes are of precise design, and the hydraulic mold clamping structure provides strong clamping force and fluent machine running.

* Machine molds are of the same height and standard designs that assist in easy change and precise fitness of molds in cavities requiring slight adjustment.

* Pre-blowing and pro-blow blowing technology assure the production of high-quality PET bottles.

* PLC controller provides equal heating, and the frequency converter provides layered heating for different design bottle molding under good production conditions.

* Machine molds are of the same height and standard designs that assist in easy change and precise fitness of molds in cavities requiring slight adjustment.

* Pre-blowing and pro-blow blowing technology assure the production of high-quality PET bottles.

* PLC controller provides equal heating, and the frequency converter provides layered heating for different design bottle molding under good production conditions.

3.Main Technical Parameters

|

Model

|

|

Unit

|

MW-SS4000

|

MW-4000B

|

|

|

Clamping System

|

Number of cabity

|

Cavities

|

4

|

4

|

|

|

|

Calmping unit

|

KG

|

40000

|

48000

|

|

|

Clamping System

|

Mold stroke

|

mm

|

90

|

125

|

|

|

|

stretching stroke

|

mm

|

260

|

330

|

|

|

|

Bottom stroke

|

mm

|

50

|

50

|

|

|

|

Cavitv pitch

|

mm

|

76.2

|

114.3

|

|

|

|

number of holder

|

PCS

|

99

|

84

|

|

|

Container

|

Max.container volume

|

ml

|

600

|

1800

|

|

|

|

Max.container height

|

mm

|

260

|

330

|

|

|

|

Max.container diameter

|

mm

|

68

|

105

|

|

|

|

Max.preform

height

|

mm

|

100

|

140

|

|

|

|

Max.neck diameter

|

mm

|

38

|

38

|

|

|

Theoretical

|

|

B/H

|

5500

|

4500

|

|

|

Electrical System

|

Heating oven qty

|

PCS

|

4*4

|

5*5

|

|

|

|

Number of lamp

|

PCS

|

4*8

|

5*10

|

|

|

|

Heating Power

|

KW

|

48

|

60

|

|

|

|

Installed Power

|

KW

|

54

|

69.5

|

|

|

|

Voltage

|

V

|

Customisation

|

Customisation

|

|

|

Air System

|

Operating Pressure

|

mpa

|

0.7-0.9

|

0.7-0.9

|

|

|

|

Blowing Pressure

|

mpa

|

2.5-3.0

|

2.5-3.0

|

|

|

|

high pressure air consumption

|

L/min

|

3.6/30

|

4.0/30

|

|

|

|

Power

|

KW

|

45

|

48

|

|

|

Chiller System

|

Power

|

HP

|

5

|

5

|

|

|

Machine

|

machine dimension

|

M

|

4.0*1.9*2.4

|

4.8*2.2*2.5

|

|

|

|

machine weight

|

KG

|

3500

|

4500

|

|

|

|

embrvo loader Size

|

M

|

2*1.2*2.7

|

2*1.2*1.7

|

|

Details Images

Product Shows

The main applications include mineral water bottles, juice, and drinking water bottles.

Transportation

1. Blowing molding machine use wooden cases packaging

2. Accessories machines use wooden cases

3. Blowing mould can install onto blowing machine or seperately packed inside wooden boxes

Related Products

Hot Searches