- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/440V

-

Current:

-

Customized Required

-

Rated Capacity:

-

Customized Required

-

Rated Duty Cycle:

-

60%-100%

-

Dimensions:

-

Depends

-

Use:

-

For welding position

-

Product name:

-

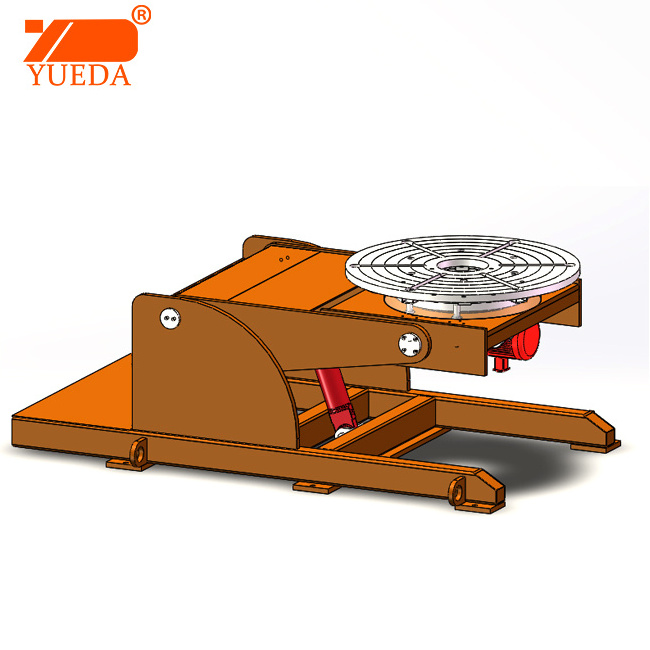

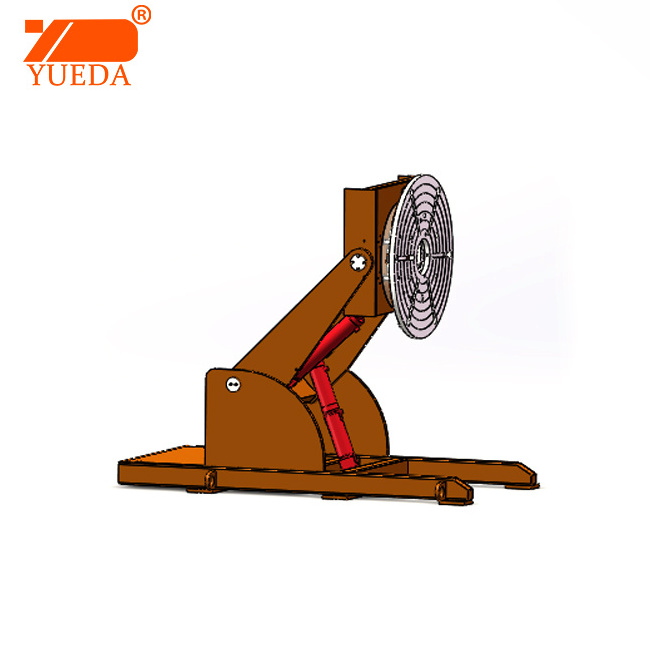

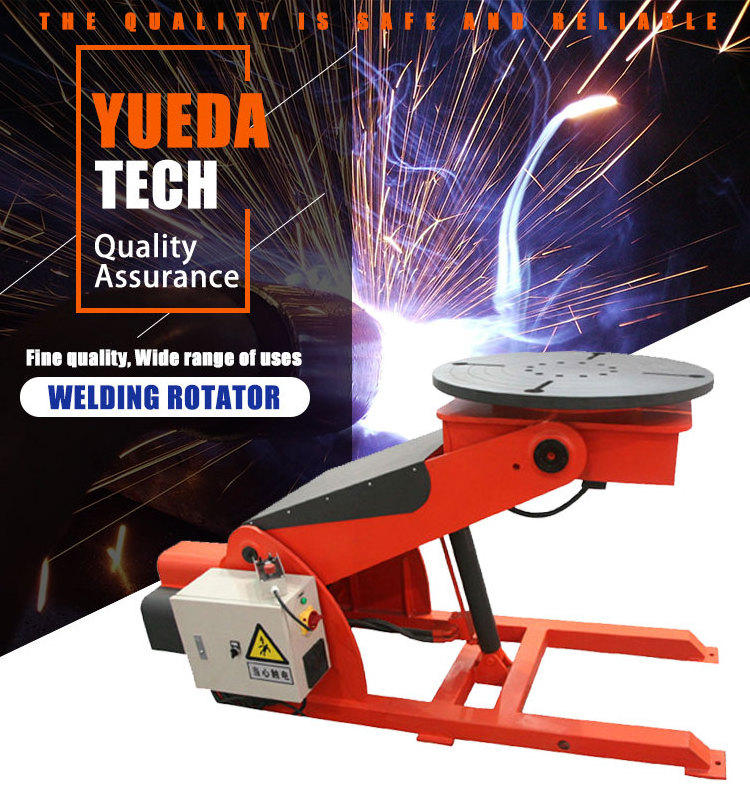

HBY03 Hydraulic Welding Positioners Rotary Table Turn Table

-

Function:

-

Positioner

-

Material:

-

Steel

-

Power supply:

-

Can be customized

-

Price:

-

Specific discussion

-

Packaging:

-

Wooden box

-

Rotation speed:

-

0.1-1RPM or customized

-

Worktable tilting degree:

-

0-90°or 0-120°

-

Weight:

-

Customized Required

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yueda

-

Weight (KG):

-

900

-

Voltage:

-

220V/380V/440V

-

Current:

-

Customized Required

-

Rated Capacity:

-

Customized Required

-

Rated Duty Cycle:

-

60%-100%

-

Dimensions:

-

Depends

-

Use:

-

For welding position

-

Product name:

-

HBY03 Hydraulic Welding Positioners Rotary Table Turn Table

-

Function:

-

Positioner

-

Material:

-

Steel

-

Power supply:

-

Can be customized

-

Price:

-

Specific discussion

-

Packaging:

-

Wooden box

-

Rotation speed:

-

0.1-1RPM or customized

-

Worktable tilting degree:

-

0-90°or 0-120°

-

Weight:

-

Customized Required

Product Description

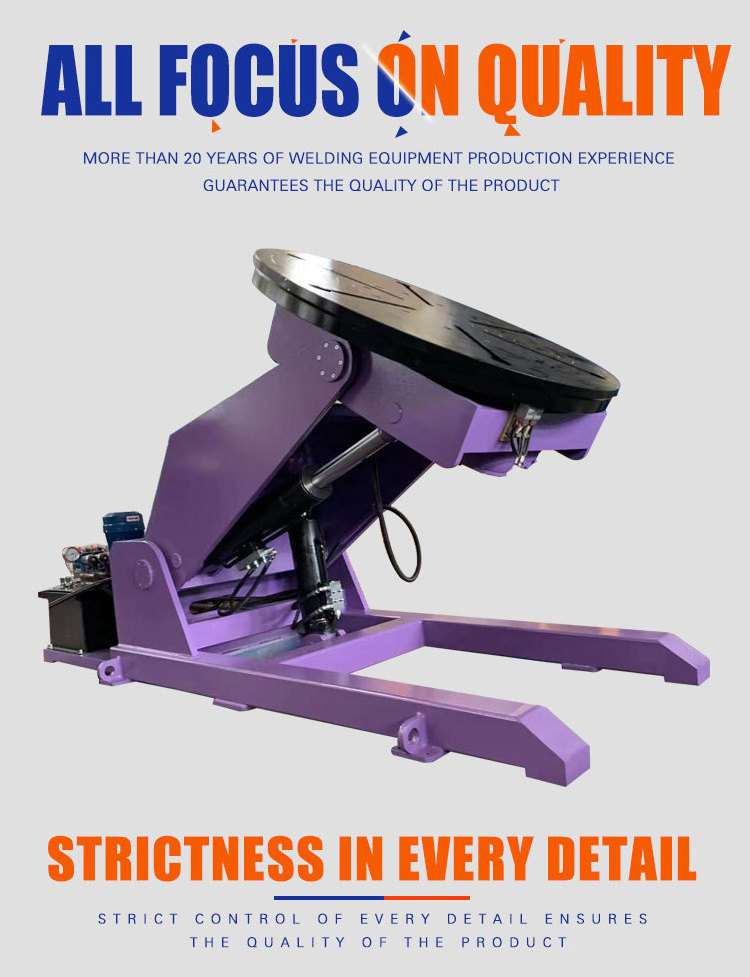

HBY03 Hydraulic Welding Positioners rotary table turn table

Product brief information

Welding positioner normally composed by worktable slewing mechanism and turnover mechanism, which let the work piece that fixed on

the worktable in the desired welding or fitting angle by worktable's lifting, turnover and slewing. And the worktable's slewing is

frequency inverter stepless speed regulation to achieve the satisfactory welding speed.

The welding positioner series are side tipping type, head and tail rotation type, head and tail lifting rotation type, head and

tail inclined type and double rotation type, etc.

It's can match with welding manipulator to form into automatic special welding machine, and it's also match with robot peripheral

equipment and robot to realize welding automation. And we also can make customized welding positioner according to clients'

different work piece and technological requirements.

Welding positioner normally composed by worktable slewing mechanism and turnover mechanism, which let the work piece that fixed on

the worktable in the desired welding or fitting angle by worktable's lifting, turnover and slewing. And the worktable's slewing is

frequency inverter stepless speed regulation to achieve the satisfactory welding speed.

The welding positioner series are side tipping type, head and tail rotation type, head and tail lifting rotation type, head and

tail inclined type and double rotation type, etc.

It's can match with welding manipulator to form into automatic special welding machine, and it's also match with robot peripheral

equipment and robot to realize welding automation. And we also can make customized welding positioner according to clients'

different work piece and technological requirements.

Details Images

Main technical parameter

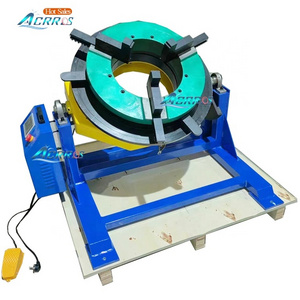

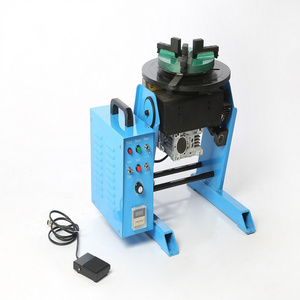

Exhibition

Product features

1) Simple structure,easy in installation and maintation.

2) Adopting advanced world famous brand components in electric parts and operation parts.

3) Worktable diameter from 300mm-2500mm to match different workpieces.

4) High load capacity from 100kg-60000kg.

5) Flexible tilting degree 0-120° to offer most suitable welding angle for workpiece.

2) Adopting advanced world famous brand components in electric parts and operation parts.

3) Worktable diameter from 300mm-2500mm to match different workpieces.

4) High load capacity from 100kg-60000kg.

5) Flexible tilting degree 0-120° to offer most suitable welding angle for workpiece.

Company information

Zhengzhou Yueda Technology Equipment Co.,Ltd(former name is Zhengzhou Yueda Automatic

Welding Equipment Co.,Ltd) which is located in Zhengzhou city,Henan province. As a high-tech enterprise with 20 years' history and

specializing in the design and manufacture of welding&cutting automation equipments. Our company is committed to provide clients

at home and abroad with one- stop automatic welding and cutting solutions.

Welding Equipment Co.,Ltd) which is located in Zhengzhou city,Henan province. As a high-tech enterprise with 20 years' history and

specializing in the design and manufacture of welding&cutting automation equipments. Our company is committed to provide clients

at home and abroad with one- stop automatic welding and cutting solutions.

Certificate

FAQ

Q: Are we a trading company or a manufacturer?

A: We are manufacturer with 20 years production history.

Q:Where is your factory located? How can I visit there?

A: Our factory is located in zhengzhou,henan Province,China.You can fly to zhengzhou airport directly.All our clients, from home

or abroad, are warmly welcome to visit us!

Q: Can machines be customized?

A: Yes, OEM and ODM are available.

Q: How can you guarantee the product quality?

A: We have strict quality control system in the production process and we welcome clients come to visit us to check the product

quality before delivery.

Q: How long is the warranty period?

A: One year.

Q: How long is your delivery time?

A: Usually within 40 days since we received deposit payment, and some standard models of machines in stock.

A: We are manufacturer with 20 years production history.

Q:Where is your factory located? How can I visit there?

A: Our factory is located in zhengzhou,henan Province,China.You can fly to zhengzhou airport directly.All our clients, from home

or abroad, are warmly welcome to visit us!

Q: Can machines be customized?

A: Yes, OEM and ODM are available.

Q: How can you guarantee the product quality?

A: We have strict quality control system in the production process and we welcome clients come to visit us to check the product

quality before delivery.

Q: How long is the warranty period?

A: One year.

Q: How long is your delivery time?

A: Usually within 40 days since we received deposit payment, and some standard models of machines in stock.

Hot Searches