- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Vansen

-

Dimension(L*W*H):

-

1400*620*1300mm

-

Weight:

-

2200 KG

-

Product name:

-

Widely-used Mining Equipment

-

Model:

-

PE250*400

-

Usage:

-

Primary Crushing

-

Material:

-

High Manganese Cast Steel

-

Max feeding size:

-

210

-

Discharge size:

-

10mm

-

Quality:

-

High Leavel

-

Crusher type:

-

Pe250*400 Jaw Crusher

-

Structure:

-

Welding Body

-

Motor power:

-

15kw

Quick Details

-

Application:

-

Aluminum stone

-

Capacity(t/h):

-

15-20

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Vansen

-

Dimension(L*W*H):

-

1400*620*1300mm

-

Weight:

-

2200 KG

-

Product name:

-

Widely-used Mining Equipment

-

Model:

-

PE250*400

-

Usage:

-

Primary Crushing

-

Material:

-

High Manganese Cast Steel

-

Max feeding size:

-

210

-

Discharge size:

-

10mm

-

Quality:

-

High Leavel

-

Crusher type:

-

Pe250*400 Jaw Crusher

-

Structure:

-

Welding Body

-

Motor power:

-

15kw

Video Details

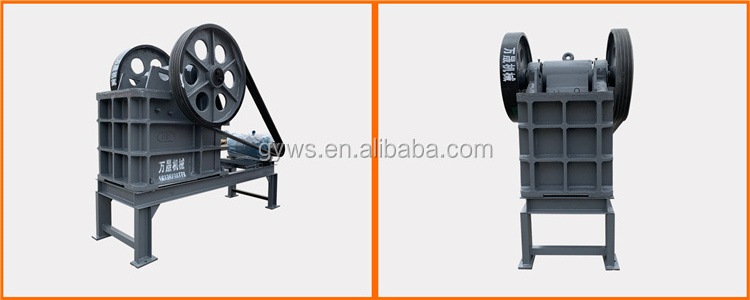

Product Display

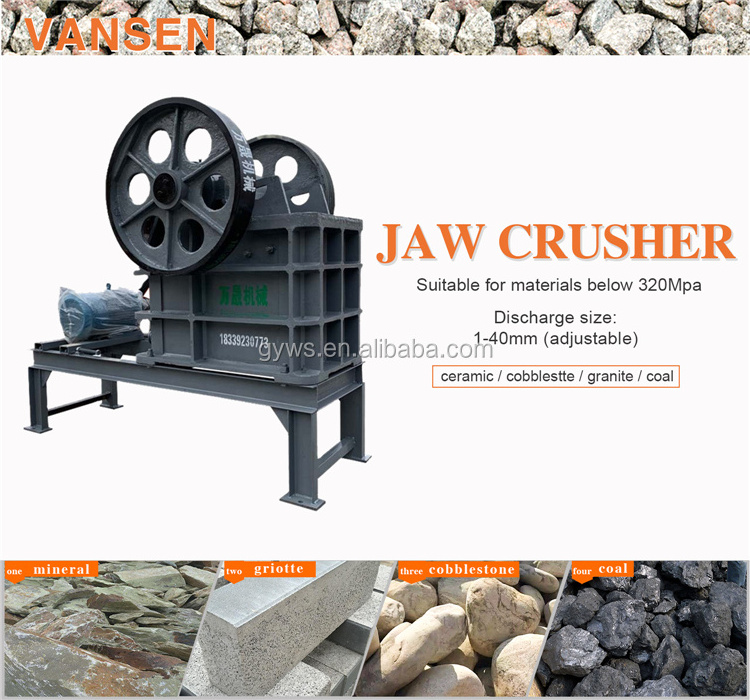

pe250*400 jaw crusher Portable gold mine coal mine crushing equipment

Jaw crusher is mainly used in metallurgy, mining, chemical industry, cement, construction, refractories and ceramics and other industrial sectors for medium and fine breaking of all kinds of medium and hard ores and rocks. Jaw crusher is suitable for crushing all kinds of soft and hard ores whose compressive strength is not higher than 245MPa

Parameter

|

Type number

|

PE-250*400

|

|

Size of feeding port (mm)

|

250*400

|

|

Maximum feed size (mm)

|

210

|

|

Adjustment range of discharge port (mm)

|

20-60

|

|

Processing capacity (T /h)

|

15-20

|

|

Eccentric shaft speed (R /min)

|

260

|

|

Motor Power (kW)

|

15

|

|

Total weight (t)

|

2.2

|

|

Overall dimension (l * w * h) (mm)

|

2000*1060*1700

|

Other product demonstrations

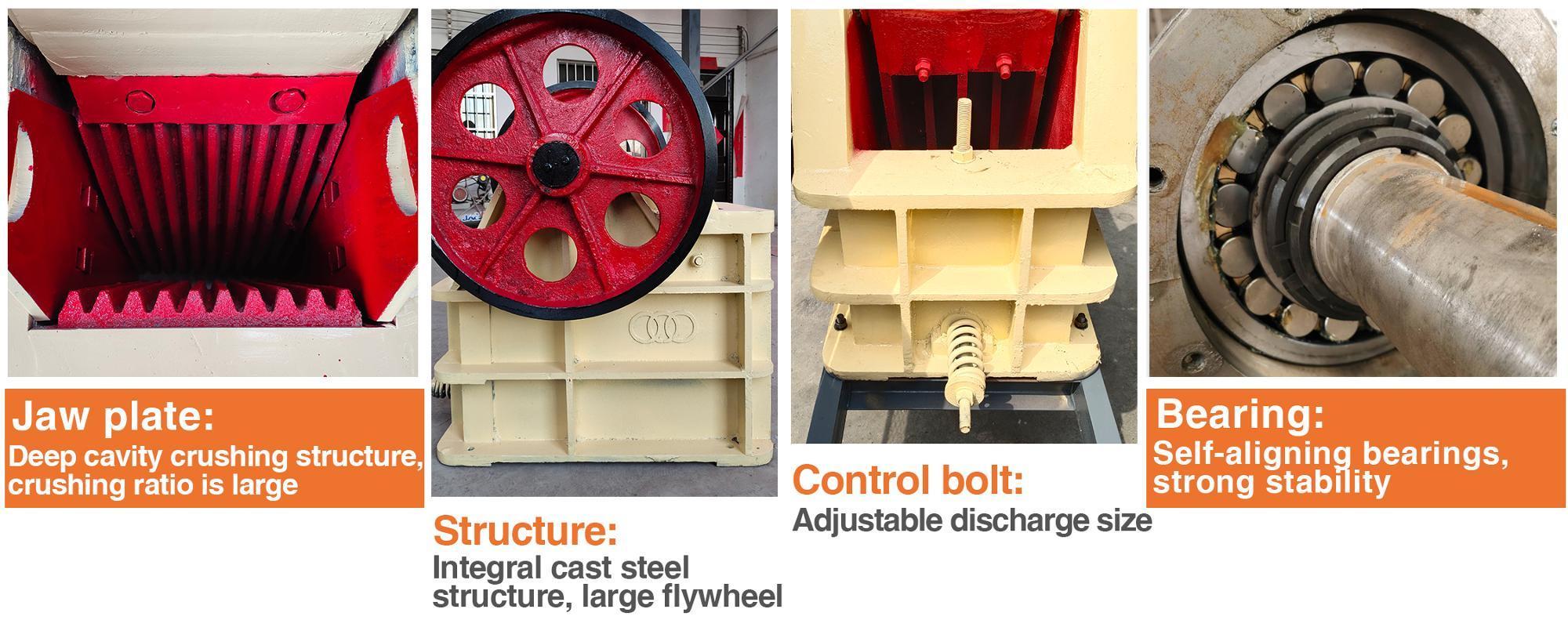

Product details display

1.Jaw plate : High manganese steel,high resistance to wear.

2.Structure : Whole welding,firm and durable

3.Bearing : Self-aligning bearings,strong stability

4.Control bolt : Adjustable discharge size

2.Structure : Whole welding,firm and durable

3.Bearing : Self-aligning bearings,strong stability

4.Control bolt : Adjustable discharge size

Operation and maintenance

1.To protect the jaw crusher,please avoid throw the iron into the machine.

2.Ensure the correct running direction,please follow the direction by the arrow.

3.Regularly replace the jaw plate and edge protector,if any wear,pleasere place it with new one.

4.Regularly lubricate the machine every eigh thours.

2.Ensure the correct running direction,please follow the direction by the arrow.

3.Regularly replace the jaw plate and edge protector,if any wear,pleasere place it with new one.

4.Regularly lubricate the machine every eigh thours.

Simple Jaw Crusher Line

Our Company

Gongyi Vansen Machinery and Equipment Co., LTD.

has gathered a large number of high-quality management talents and skilled scientific research elites. After years of hard exploration, we have established a complete and effective service system, and built an experienced service team. We not only provide free site planning, design and installation basic drawings and flow charts, but also provide professional technical training for customers, and send technicians to guide installation and commissioning of equipment on site.

Our Factory

Certificate

Packing and delivery

FAQ

Q1: Are you trading company or manufacturer?

A1:We are professional manufacturer, and our factory mainly produce crushing and milling equipment, wood crushing

equipment,construction equipment, brick production equipment, etc. Our products have been exported to more than 50 countries of Asia, South America, Africa, and get a good reputation in the world.

Q2: Installation?

A2:Our senior engineer will supply installation and training service on-line or on-site.

Q3: What about Warranty?

A3:Vansen Machinery grants our customers a twelve-month-period warranty from the date of delivery for machines exported from us.During the warranty period, in case any defect of material or workmanship occurred with spare parts in normal operation, we will at our discretion replace or repair the defective parts freely.

Q4: What about After-sale service?

A4:All equipment produced by Vansen is of the highest standard and our customers rarely experience mechanical failures. If there are

any problems, our engineers and technicians will respond with in 12 hours of customer notification.

Q5. For providing you the right model, we need to know the following information:

A5:

(1)* What is the raw material for the production line?

(2)* What is the capacity per hour you required?

(3)* What is the maximum input size of the raw material?

A1:We are professional manufacturer, and our factory mainly produce crushing and milling equipment, wood crushing

equipment,construction equipment, brick production equipment, etc. Our products have been exported to more than 50 countries of Asia, South America, Africa, and get a good reputation in the world.

Q2: Installation?

A2:Our senior engineer will supply installation and training service on-line or on-site.

Q3: What about Warranty?

A3:Vansen Machinery grants our customers a twelve-month-period warranty from the date of delivery for machines exported from us.During the warranty period, in case any defect of material or workmanship occurred with spare parts in normal operation, we will at our discretion replace or repair the defective parts freely.

Q4: What about After-sale service?

A4:All equipment produced by Vansen is of the highest standard and our customers rarely experience mechanical failures. If there are

any problems, our engineers and technicians will respond with in 12 hours of customer notification.

Q5. For providing you the right model, we need to know the following information:

A5:

(1)* What is the raw material for the production line?

(2)* What is the capacity per hour you required?

(3)* What is the maximum input size of the raw material?

Hot Searches