- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Baichy

-

Dimension(L*W*H):

-

Refer to per model

-

Weight:

-

500 KG

-

Product name:

-

Coal Coke Gypsum Crushing Machine 2PG610X400 Double Roller Crusher

-

Spare parts supply:

-

Anytime

-

After sale Service:

-

Life Long Operation Time

-

Color:

-

Customer Requirement

-

Quality:

-

Advanced Technology

-

Price:

-

Competetive (can Discuss

-

Advantage:

-

High Efficiency Low Energy

-

Features:

-

High Efficiency Low Cost

-

After-sale service:

-

24 Hours Service Hotline

-

Factory visit:

-

Welcomed Warmly

Quick Details

-

Application:

-

Crushing stone,rock,etc

-

Capacity(t/h):

-

15-40

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Baichy

-

Dimension(L*W*H):

-

Refer to per model

-

Weight:

-

500 KG

-

Product name:

-

Coal Coke Gypsum Crushing Machine 2PG610X400 Double Roller Crusher

-

Spare parts supply:

-

Anytime

-

After sale Service:

-

Life Long Operation Time

-

Color:

-

Customer Requirement

-

Quality:

-

Advanced Technology

-

Price:

-

Competetive (can Discuss

-

Advantage:

-

High Efficiency Low Energy

-

Features:

-

High Efficiency Low Cost

-

After-sale service:

-

24 Hours Service Hotline

-

Factory visit:

-

Welcomed Warmly

Small Portable Sand Making Crusher Double Teeth Crusher Price Coal Coke Gypsum Crushing Machine 2PG610X400 Double Roller Crusher

Product brief introduction

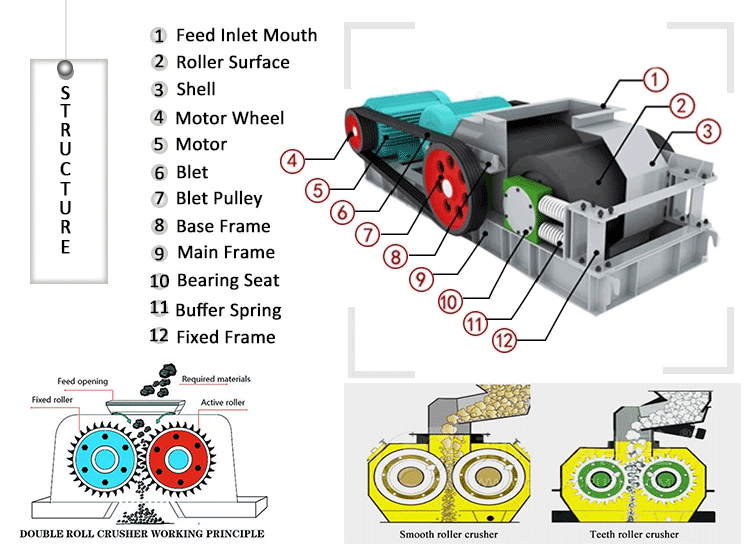

Roll crusher is also called double roll crusher, double teeth roll crusher etc. The surface of roller crusher are made of high manganese steel, which can stand up to heat treatment. Double roller crusher is suitable for rough and intermediate crushing of brittle materials in such industries as cement, chemical industry, electric power, mine, building materials and metallurgy. The grain size of the input material is large, the particle size of the output product can be controlled, and it is possible to effectively destroy the material whose compressive strength is less than 160 MPa

Advantage

1.The rollers is wear-resisting chromium molybdenum copper alloy with long service.

2.The gap between the rollers is adjustable, so that the output size and capacity will be changed accordingly.

3.This crusher is equipped with motorless scraper. When the raw material has high moisture content, it can avoid to affect the output size and avoid sticking the roller or blocking the machinehe.

4.According to requirement, it could be in flat roller or toothed roller.

Working principle

The materials to be crushed fall from the feeding mouth to the space between the two rolls.After being squeezed and crushed, the final products will naturally fall. When there are too hard materials or materials that cannot be crushed, the rolls of the roller crusher will automatically withdraw under the effect of hydraulic cylinder or spring to increase the gap between the rolls, and the too hard materials or the materials that cannot be crushed will fall down.Thus protecting the machine from being damaged. There is a certain gap between the two rolls that rotate at the opposite direction, and the maximum discharging granularity of the final products can be controlled by changing this gap. Double roller crusher's the materials by relying on the two round rollers rotating at the opposite direction, and four-roll crusher crushes the materials by relying on the two pairs of round rollers rotating at the opposite direction.

| Model | Roller Diameter (mm) | Roller Length (mm) | Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Motor Power (kw) |

| 2GP-400X250 | 400 | 250 | ≤ 25 | 1-8 | 5-10 | 5.5*2 |

| 2GP-500X450 | 500 | 450 | ≤ 30 | 1-15 | 10-20 | 11*2 |

| 2GP-610X400 | 610 | 400 | ≤ 40 | 1-20 | 13-35 | 15*2 |

| 2GP-750X500 | 750 | 500 | ≤ 40 | 2-20 | 15-40 | 18.5*2 |

| 2GP-800X600 | 800 | 600 | ≤ 40 | 3-20 | 20-50 | 22*2 |

| 2GP-1000X500 | 1000 | 500 | ≤ 120 | 3-20 | 30-60 | 37*2 |

| 2GP-1100X600 | 1100 | 600 | ≤ 150 | 3-20 | 50-80 | 37*2 |

| 2GP-1000X1000 | 1000 | 1000 | ≤ 120 | 3-20 | 60-80 | 45*2 |

1. Are you manufacture or trading company?

We are factory, established in 2003.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at lowest cost.

5. If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.