Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XINHE

-

Voltage:

-

Country Voltage

-

Dimension(L*W*H):

-

8900*1550*1150

-

Power (kW):

-

37

-

Weight:

-

4500 KG

-

Keywords:

-

PVC Pipe Extruder Line

-

Inverter:

-

TECO Brand

-

Machine color:

-

Custmer's Requirement

-

Certification:

-

ISO9001:2008/CE

-

Supply Ability:

-

100 Set/Sets per Year

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw Speed (rpm):

-

35 rpm, 35 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XINHE

-

Voltage:

-

Country Voltage

-

Dimension(L*W*H):

-

8900*1550*1150

-

Power (kW):

-

37

-

Weight:

-

4500 KG

-

Keywords:

-

PVC Pipe Extruder Line

-

Inverter:

-

TECO Brand

-

Machine color:

-

Custmer's Requirement

-

Certification:

-

ISO9001:2008/CE

-

Supply Ability:

-

100 Set/Sets per Year

Video Show

Overview

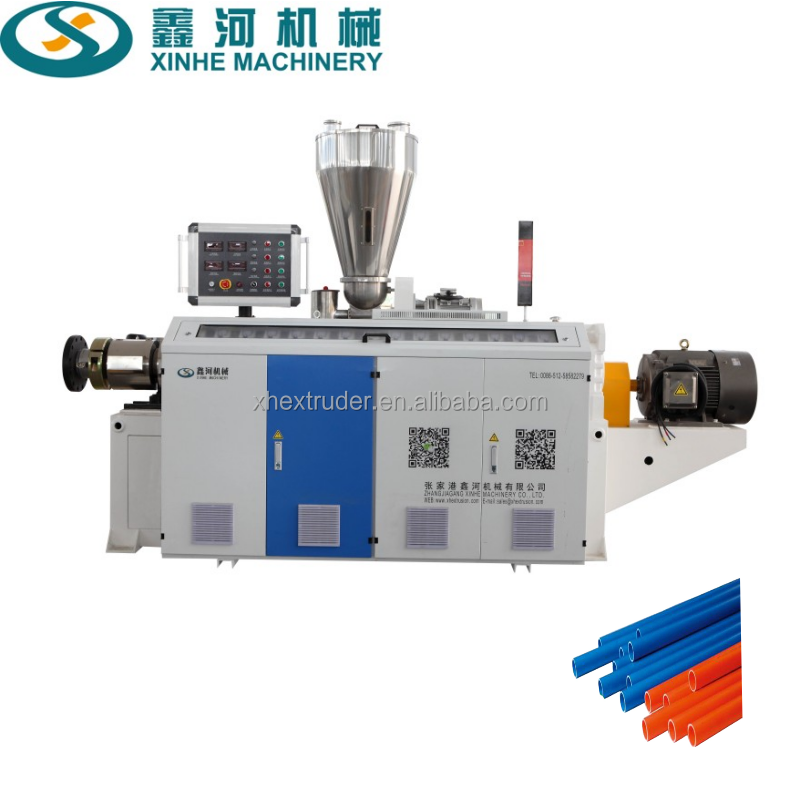

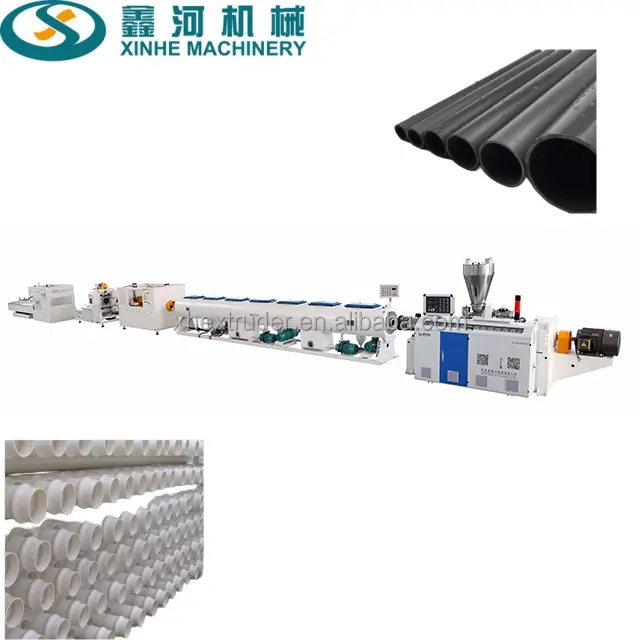

Plastic PVC UPVC CPVC Pipe Making Machine

1.PVC pipe extrusion line is mainly used in the production of pressure water pipes, agriculture irrigation, building or city

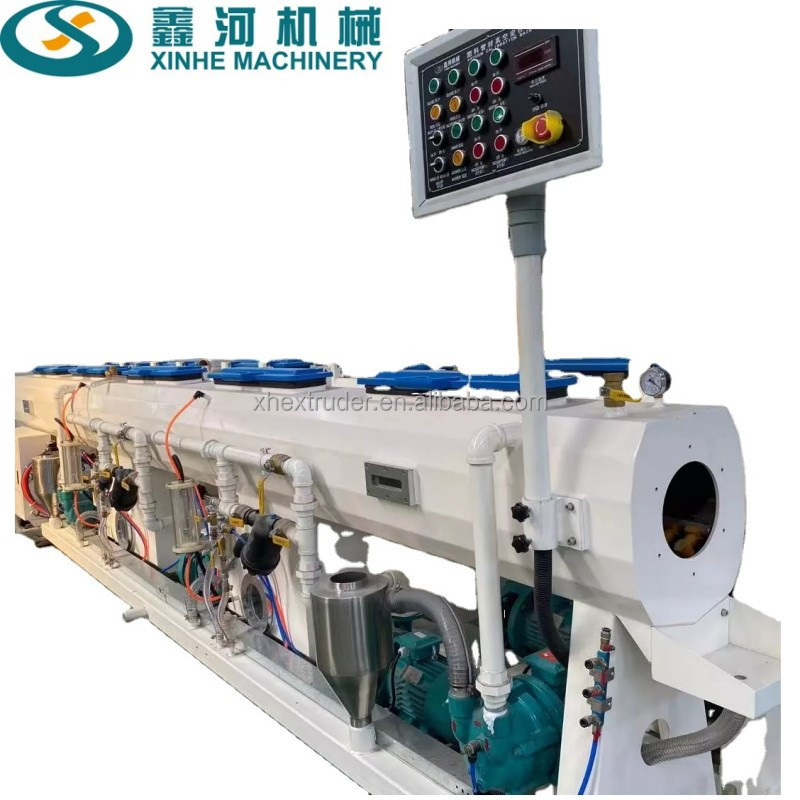

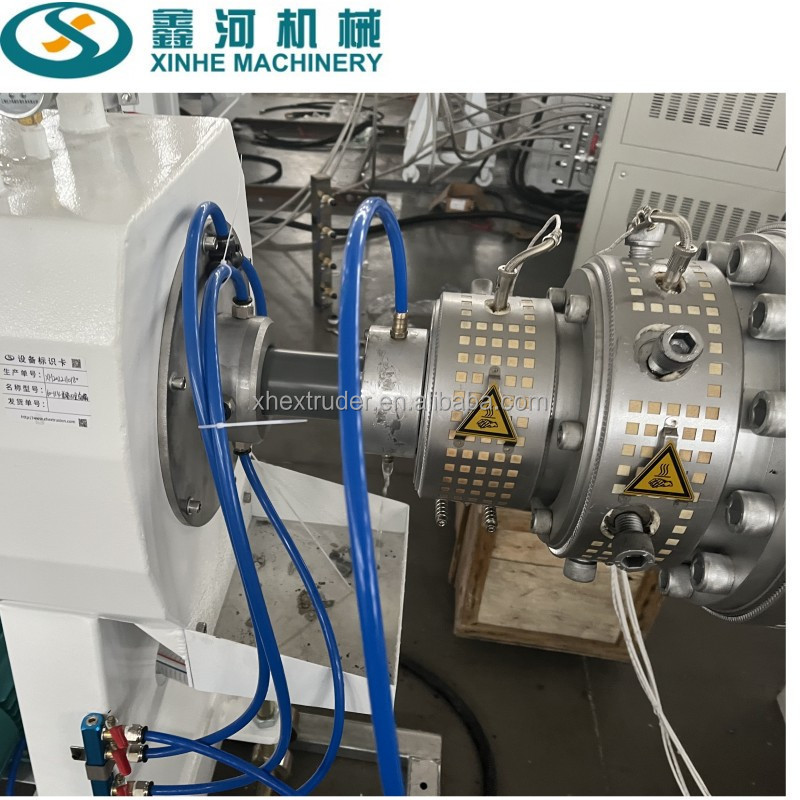

drainage and Sewage and constructional plumbing cable laying etc. The unit consists of Conical twin screw extruder, PVC pipe mould-Vacuum calibration tank-Haul-off machine-Planetary Saw Cutting machine-Tripping table/Belling machine.

2.Producing pipe diameter range: Φ160mm-Φ400mm. And the line can be equipped with comptroller thickening instrument, computer ink-jet printer, crusher, shredder, pulverizer ,water chiller, air compressor etc. to achieve the production and manufacture of high-grade tubing.

3.Advanced design for screws and barrel supplies powerful safeguard for the PVC plasticization.

3.Advanced design for screws and barrel supplies powerful safeguard for the PVC plasticization.

Product parameters

|

Model

|

PVCG-2-50

|

PVCG-4-25

|

PVCG-110

|

PVCG-160

|

PVCG-250

|

PVCG-315

|

PVCG-400

|

PVCG-630

|

|

Extruder

|

SJZ51/105

|

SJZ65/132

|

SJZ51/105

|

SJZ65/132

|

SJZ65/132

|

SJZ80/156

|

SJZ80/156

|

SJZ92/188

|

|

PIPE Range

|

ø16-ø50

|

ø16-ø25

|

ø20-ø110

|

ø50-ø160

|

ø50-ø250

|

ø110-ø315

|

ø160-ø400

|

ø315-ø630

|

|

Total Length

|

17000

|

18000

|

17000

|

18000

|

20000

|

20500

|

28000

|

30000

|

Details Images

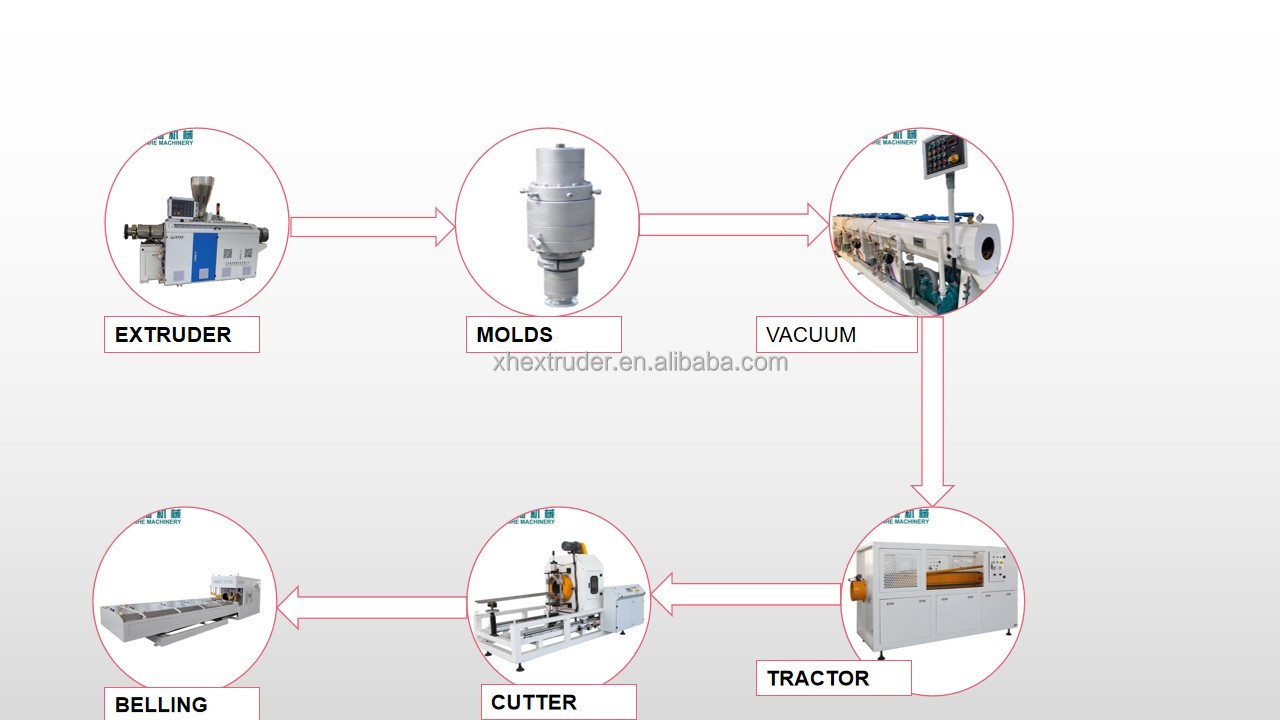

Production process

Production process: raw materials + additives preparation → mixing → conveying and feeding → forced feeding → Cone-type twin-screw extruder → extrusion mold → sizing sleeve → spray vacuum setting box → immersion cooling water tank → ink printer → track tractor → knife lift cutting machine → pipe stacking rack → Finished product testing and packaging

Final Product

Recommend Products

Hot Searches