Design:

- Product Details

- {{item.text}}

Quick Details

-

Cooling Capacity:

-

100 tons

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

HAOCOOL

-

Voltage:

-

110V/220V/380V~440V, 50HZ/60HZ

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

200 KG

-

Product Name:

-

Chiller/Freezer/Blast Freezer Room

-

Application:

-

Cold Storage Room Freezer Room

-

After-sales Service:

-

Overseas service center available

-

Door type:

-

Sliding / Swing / Hinged Door

-

Panel thickness:

-

50mm/75mm/100mm/120mm/150mm/200mm

-

Control system:

-

Digital Control or Remote Monitoring

-

Thickness of Color Steel:

-

0.426/0.5/0.6/0.8mm

-

Valve:

-

Danfoss

-

Refrigerant:

-

R22/R404a/R507

Quick Details

-

Temperature:

-

-75℃ ~ +40℃

-

Compressor brand:

-

Copeland, Bitzer, Emerson, Frascold, Refcomp

-

Panel Thickness:

-

100mm, 200mm, 120mm, 75mm, 50mm, 150mm

-

Cooling Capacity:

-

100 tons

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

HAOCOOL

-

Voltage:

-

110V/220V/380V~440V, 50HZ/60HZ

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

200 KG

-

Product Name:

-

Chiller/Freezer/Blast Freezer Room

-

Application:

-

Cold Storage Room Freezer Room

-

After-sales Service:

-

Overseas service center available

-

Door type:

-

Sliding / Swing / Hinged Door

-

Panel thickness:

-

50mm/75mm/100mm/120mm/150mm/200mm

-

Control system:

-

Digital Control or Remote Monitoring

-

Thickness of Color Steel:

-

0.426/0.5/0.6/0.8mm

-

Valve:

-

Danfoss

-

Refrigerant:

-

R22/R404a/R507

Specification

Walk in Cold Room and Freezer Room

HAOCOOL is a high-growth cold chain company headquartered in Shanghai, China, specializing in designs, installs and commissions refrigeration solutions for industrial and commercial customers. HAOCOOL has 20 years of experience in the cold room market. Customers can easily apply HAOCOOL' s refrigeration and cold room solutions into their business processes. Whether you are looking for cold room, refrigeration condensing units, insulation panels, evaporator air coolers.

With decades of industry experience, we are your go-to source for all your refrigeration needs. We supply a wide range of refrigeration products, including insulation panels, refrigeration condensing units, evaporators, refrigeration accessories, tunnel freezers, and more. Our expert team is here to guide you through the equipment selection process, design a customized solution, and provide you with purchase plans that meet your unique needs. We also provide installation, debugging, and after-sales maintenance services to ensure your system runs smoothly for years to come. If you have any questions or purchases, feel free to chat with our technical sales team.

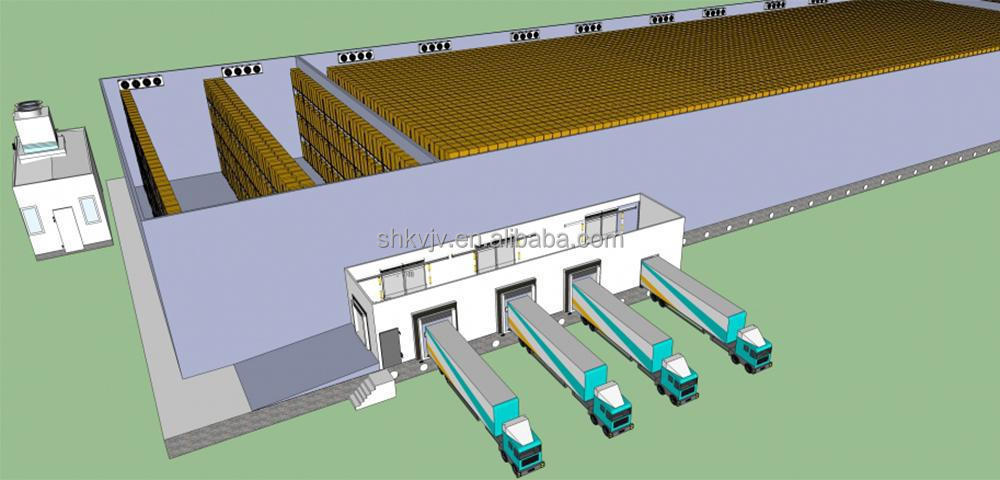

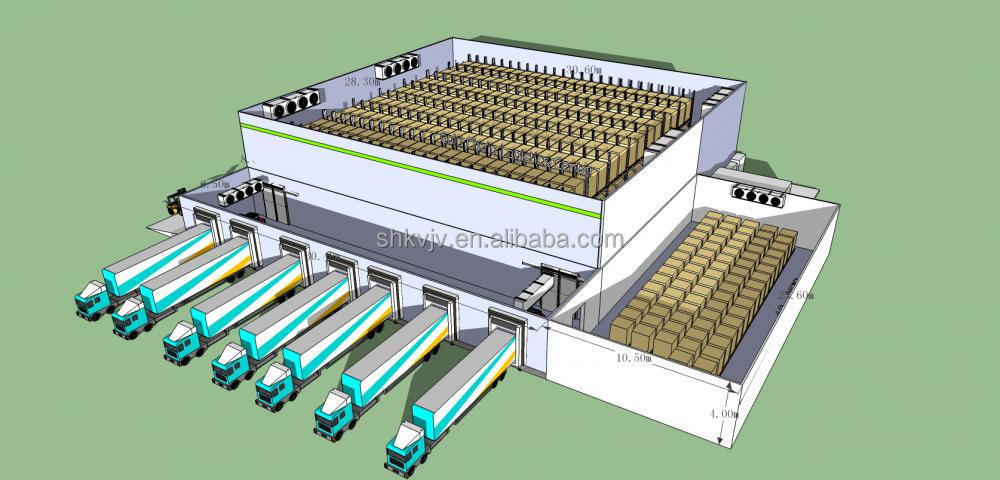

Construction Designing

The Haocool design team has years of combined experience. Our engineers have accumulated an extensive amount of industry knowledge and expertise.

HAOCOOL offers one-stop services. As long as you give us a general intention, we will provide you with the best project plan working with you to coordinate a design plan, providing quotations for different brands of equipment, engineering installation, and following it all up with after-sales services.

5000t cold storage

Seafood low-temperature cold storage

Small-scale food cold storage

Logistics cold storage warehouse

Steel structure cold storage

Our Plan Contains:

√

Outline the project:

the complete summary design of the cold storage unit

√ Design reference: Our design accords with all design specifications and standards

√ Refrigeration equipment selection and calculation: Design and configure equipment units according to the requirements and give corresponding calculations

√ Design reference: Our design accords with all design specifications and standards

√ Refrigeration equipment selection and calculation: Design and configure equipment units according to the requirements and give corresponding calculations

√

Main technical data of selected cooling unit

√ Detailed configuration table of the selected unit

√ The structure of cold storage: We will provide general layout, equipment layout and process flow chart.

√ Control system: It contains control mode, alarm and protection function, data monitoring and historical record and system parameters menu

√ Detailed configuration table of the selected unit

√ The structure of cold storage: We will provide general layout, equipment layout and process flow chart.

√ Control system: It contains control mode, alarm and protection function, data monitoring and historical record and system parameters menu

Design drawings of cold storage for agricultural products

Completion of cold storage for agricultural products

Cost Budgeting

20,000m³ Cold storage of logistics base

Outside of cold storage

Before we begin cost budgeting, we first need to know the dimensions and parameters needed for your cold storage unit as well as the intended application. We can design different temperature ranges according to different parameters and usages.

After knowing the size, temperature, application and other basic information, we will choose suitable refrigeration units, thermal insulation materials and cold storage accessories and compile a complete cost plan.

What are the typical costs associated with cold storage units?

√ Storehouse cost:

such as polyurethane board, reinforced beam or column, roof and floor. If civil engineering is needed,

they should be brought in according to the specific conditions.

√ Unit cost: Cooling compressor units are the most important parts of cold storage projects.

√ Accessories cost: These include cold storage doors, cooling fans, cooling towers, pumps, pipes, fluid reservoirs, separators, circuits, switches and so on.

√ Accessories cost: These include cold storage doors, cooling fans, cooling towers, pumps, pipes, fluid reservoirs, separators, circuits, switches and so on.

√ Incidental cost: Such as transportation cost, construction cost and the cost of defrosting or drainage systems.

50,000m³cold storage

Outside of cold storage

Factors affecting construction cost of cold storage:

√

Cold storage size

The cold storage is calculated by the size of the cube. The larger the volume of cold storage, the lower the price of cold

store. So it should be built according to its own situation.

√

Different configuration schemes of cold storage depend on different prices

Different configuration schemes of cold storage depend on the prices of different suppliers. Customers can choose

according to their requirements. Different schemes can achieve different cooling effects and service life and maintenance costs are also variable.

√

Thermal insulation material

Thermal insulation materials are one of the largest factors of price variation for small-scale cold

storage. Whether the

insulation material is good will affect power consumption and cooling effects in later stages.

√

Environmental conditions

The environment temperature and humidity of cold storage will affect the selection of cold storage materials directly.

√ Special function

√ Special function

Some cold storage units with special functions are typically more expensive than standard cold storage

units. Some

examples of special functions include controlled atmosphere cold storage systems and explosion-proof warehouses.

√

Refrigeration equipment

Depending on the cooling scheme and requirements, different refrigeration equipment will be more suitable for certain

performance metrics. The price will vary by brand and power.

√

Partition

The number of partitions can affect the price as they can alter the efficiency of the cold storage unit in general for better

or worse depending on the quantity and installation design.

The data needed to provide:

(1) The specific application and requirements of cold storage

(2) The area and volume of cold storage. Or length, width and height data of cold storage

(3) Whether the external wall of cold storage is completed

(4) The using temperature of cold storage

(2) The area and volume of cold storage. Or length, width and height data of cold storage

(3) Whether the external wall of cold storage is completed

(4) The using temperature of cold storage

Material and Equipment Purchasing

Main configuration:

A good refrigeration project consists of high quality thermal insulation materials, a compressor unit,

auxiliary refrigeration unit and automatic control system.

auxiliary refrigeration unit and automatic control system.

Haocool has professional supporting factory to provide products for the whole project, including building materials, thermal insulation materials, doors, refrigeration equipment, electrical equipment, lighting equipment and monitoring equipment.

1)

Insulated Wall Panels & Floor Panels

:

The cold storage panel production base mainly produces thermal insulation panel, cold storage panel, cold storage door, camlock panels and slip joint panels. The annual production output can reach about 150 thousand ㎡.

The flame-retardant properties of insulation board reaches B1 grade, and cold storage board has passed European Union CE certification and ISO9001 quality system certification.

The thickness of polyurethane cold room panel can be customized to 50mm/75mm/100mm/120mm/150mm/200mm.

Door production area

Finished product packaging

Transportation

Color steel insulation panel

Insulation board with embossed aluminum cladding

Flame-retardant test on site

2)

Condensing Unit:

The Haocool unit factory manufactures refrigerating unit equipment.

Our common unit can meet cold storage projects that less than 50 thousand tons. We mainly choose international well-known brands like German Bitzer, Emerson Copeland, Italian Frascold and RefComp.

Manufacturing shop

Welding area

Welding area

Parallel units

Bitzer compressor

Protection equipment

3)

Condensing Accessories:

Automatic control system contains condenser, evaporator and throttle device.

Condenser Unit

Evaporator

Throttle device

4)

Automatic Controlling System

:

Electrical component

Temperature monitoring

PLC touch screen control panel

Constructing and Installing

Cold room mainly consist of cold room panels, cold room doors, condensing unit, refrigeration system, This is a system engineering which consists of many precision components, so it should be constructed and installed strictly according to the design scheme.

Haocool has a professional engineering team and experienced construction crews familiar with the characteristics of all relevant refrigeration equipment used in the operation of cold storage systems. They combine to provide complete construction tasks on time with high quality on customer sites.

Installation steps:

1. Preparing work

We will prepare cold storage project plans and other construction materials. All kinds of materials for cold storage are

customized according to customers.

After cleaning the construction site, we will transport all installation materials to the site. And then we will check the quality and type of materials, after that we will install the cold storage system.

2. Installing the cold storage body

Prefabricated cold storage units are assembled with cold storage board. The body generally needs to be smooth and tight, without a hollow-sense, in order to ensure its load bearing, anti-freezing, and moisture proof performance.

3. Installing refrigeration equipment

The refrigeration system includes evaporators and units outside the cold storage. All equipment should accord with installation and construction specifications with corresponding protective measures.

4. Installing the electronic control system

The electric control system mainly includes electrical appliances, electric doors, lamps and some other electrical equipment. The circuit in cold storage must be arranged reasonably. The power supply needs to be a stable three-phase four-wire. Or independent power or backup power can be used as well.

5. Connecting refrigeration system

Refrigerating units and electronic control systems of cold storages should be connected by wire and copper tube. The connection should be close and corresponding measures for insulation and protection are required.

6. Debugging cold storage

After installed and connected cold storage parts, the cold storage can be debugged.

We will adjust the parameters of the cold storage to make it reach the designed temperature according to customer needs. After confirming the operation of each part, the cold storage can be delivered.

We will prepare cold storage project plans and other construction materials. All kinds of materials for cold storage are

customized according to customers.

After cleaning the construction site, we will transport all installation materials to the site. And then we will check the quality and type of materials, after that we will install the cold storage system.

2. Installing the cold storage body

Prefabricated cold storage units are assembled with cold storage board. The body generally needs to be smooth and tight, without a hollow-sense, in order to ensure its load bearing, anti-freezing, and moisture proof performance.

3. Installing refrigeration equipment

The refrigeration system includes evaporators and units outside the cold storage. All equipment should accord with installation and construction specifications with corresponding protective measures.

4. Installing the electronic control system

The electric control system mainly includes electrical appliances, electric doors, lamps and some other electrical equipment. The circuit in cold storage must be arranged reasonably. The power supply needs to be a stable three-phase four-wire. Or independent power or backup power can be used as well.

5. Connecting refrigeration system

Refrigerating units and electronic control systems of cold storages should be connected by wire and copper tube. The connection should be close and corresponding measures for insulation and protection are required.

6. Debugging cold storage

After installed and connected cold storage parts, the cold storage can be debugged.

We will adjust the parameters of the cold storage to make it reach the designed temperature according to customer needs. After confirming the operation of each part, the cold storage can be delivered.

Attention after installation:

When the cold storage and refrigeration equipment have just been installed, or ignored for a long time and then reused, they should undergo comprehensive inspection. Confirm that indicators are normal, they should only be used under the guidance of technicians.

√ When using, it is necessary to avoid collision and scratching to cold storage components. Damage could cause deformation and corrosion, which could even diminish the effectiveness of the insulation.

√ Because prefabricated cold storage is constructed from thermal insulation board, there are some gaps between the boards. When constructing, these gaps will be sealed with sealant in order to prevent air and moisture from entering.

√ If small-scale prefabricated cold storage uses thermal insulation board as the storage body, ice and water on the ground of the unit should be avoided. If there is some ice buildup, do not strike the ice to break it up to avoid damaging the cold storage floor.

Maintenance and Service

Security Guarantee:

Considering that long distance international trade and the maintenance is not as timely as domestic, we will avoid failures as far as possible from the source. Specific measures include:

The circuit of unit adopts the parallel mode generally, so each unit can run independently. If there is a sudden failure in one unit, the normal refrigeration by other units will not be affected. So the safety is improved.

Main units choose high quality international brand such as Bitzer and RefComp in order to ensure the stability of refrigeration performance.

We will combine some factors like scale of cold storage and requirements of temperature to design different number of standby units, which can be used in rotation. So it can improve the service life of units and ensure stable refrigeration performance of cold storage.

We will prepare spare parts for quick-wear parts that may need to be replaced in the later period like expansion valve and cold storage lamp in project delivery time. After that we will also provide quick-wear parts for customers at a favorable price.

1. The guarantee period for refrigeration equipment is 12 months after acceptance. If there are quality problems in warranty period, we will provide service for free.

2. Our staff who provide after-sale service will visit customers regularly or irregularly to ensure service system.

3. We will provide maintenance service of units and help the overhaul of unit for customers.

4. In order to ensure units can maintain operating stability after delivery of the cold storage project, Haocool will communicate with the customer regularly, know its service conditions and solve customer's problems in real-time.

About Us

Shanghai Haocool Industrial Co.,Ltd was established in 2009, headquartered in Shanghai,China, We have more than 20 years cold storage project experience. Now set up 15 Branch companies and overseas offices.

HAOCOOL specialized in condensing unit, compressor, evaporator, condenser, cold room panels, refrigeration equipment and related accessories, supplying cold room one-stop solution. We provide the customized products including OEM and ODM services. Our product are certified with CE, ROHS, SASO, NSF, ISO 9001.

HAOCOOL have completed thousands of domestic and overseas projects, our products exported more than 50 countries. We

have excellent teams who focus on product development & design. Our factory owns advanced production machines and excellent technology to guarantee quality control strictly.

Welcome to have a chat with our technical sales team.

Certifications

Hot Searches