- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Abelplas

-

Voltage:

-

380v 3phase 50hz

-

Dimension(L*W*H):

-

20m*2m*1.8m

-

Weight:

-

14ton

-

Output (kg/h):

-

100 - 300

-

Certification:

-

CE,ISO9001

-

Name:

-

wood plastic composite door frame making machine

-

Experience:

-

15 years

-

Contactor:

-

Delixi

-

Max capacity:

-

240kg/h

-

Extruder power:

-

45/75kw

-

Raw material:

-

wood plastic composite

-

Main products:

-

wpc profile/sheet/panel

-

Characters of end products:

-

Fire resistant,anti-ultraviolet,sawed,painted,drilled,nailed,planed

-

Machine advantages:

-

High output,keen price,high stability

Quick Details

-

Screw Design:

-

Double-screw

-

Screw diameter (mm):

-

65 mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Abelplas

-

Voltage:

-

380v 3phase 50hz

-

Dimension(L*W*H):

-

20m*2m*1.8m

-

Weight:

-

14ton

-

Output (kg/h):

-

100 - 300

-

Certification:

-

CE,ISO9001

-

Name:

-

wood plastic composite door frame making machine

-

Experience:

-

15 years

-

Contactor:

-

Delixi

-

Max capacity:

-

240kg/h

-

Extruder power:

-

45/75kw

-

Raw material:

-

wood plastic composite

-

Main products:

-

wpc profile/sheet/panel

-

Characters of end products:

-

Fire resistant,anti-ultraviolet,sawed,painted,drilled,nailed,planed

-

Machine advantages:

-

High output,keen price,high stability

wood plastic composite door frame making machine

Our wood plastic composite door frame making machine is high technical and easy to operated. Also CE approved. It can be used to produce various PVC/WPC products, such as wpc door frames, wpc foam board, wpc floor, wpc door, ect. WPC products is made from PE/PP/PVC+wood powder+additives. It is a new generation of green environmental material and very popular in the world at present. WPC products have both wood and plastic double properties, and it's mechanical performance is better than wood.It also have the features of water-proof ,fire-resistant,anti-corrosion,anti-moth,100% recycled.

The whole wood plastic composite door frame making machine includes the following parts:

1. Mixing Machine

2. Spring Feeder

3. Twin Screw Extruder

4. Profile Moulds (make according to your requirements)

5. Vacuum Calibration Table

6. Hauling Off Machine

8. Cutting Machine

9. Stacker

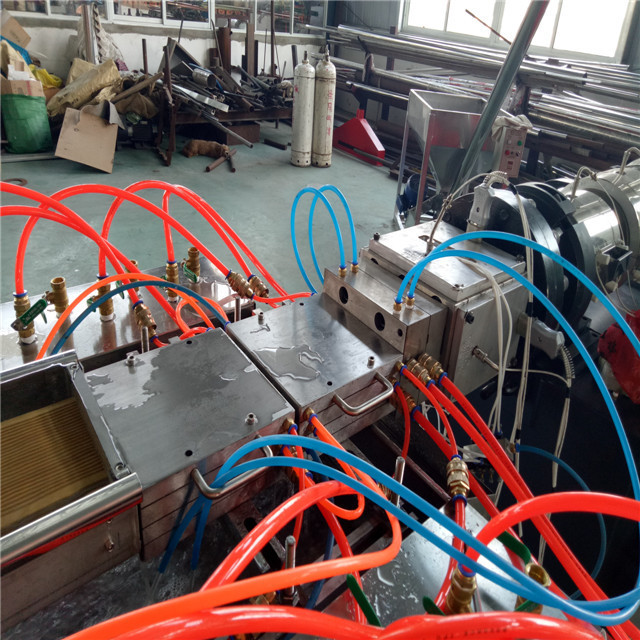

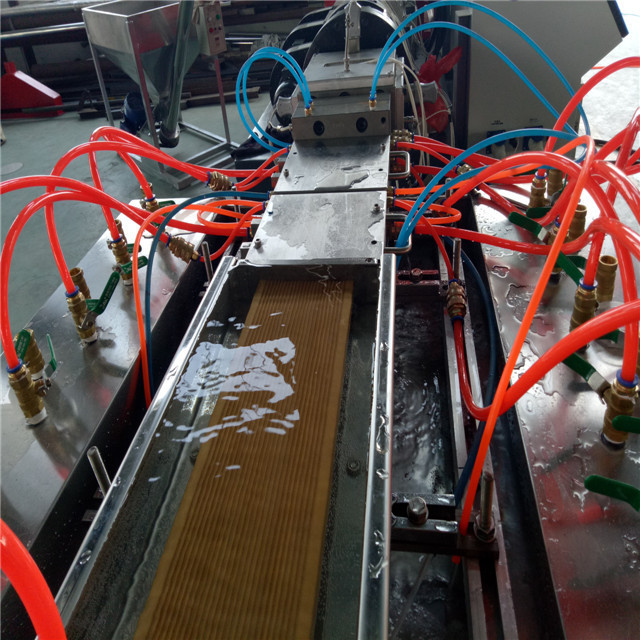

Machine photos:

1.Extruder

2.Mould

3.Vacuum Calibration Tank

4.Haul-off Machine

5.Cutter

6.Stacker

Production Flow:

Powder Mixer → Spring Feeder → Extruder Machine → Mold → Vacuum Calibration Table → Hauling Off Machine→ Cutting Machine → Stacker

1.Suitable to produce both PVC wood and PE PP wood WPC profile, such as WPC floor, WPC skirting, WPC Deck and so on.

2. Conical twin-screw extruder is perfect with WPC powder or granular material.

3.Mould designed by different kinds of profile customer required.

4.Supply formula guide and staple raw material purchase.

One Step Method Production Line Parameters:

|

Main technical data |

|||||

|

Mode |

Products max width (mm) |

Max capacity

|

Extruder mode |

Extruder power (kw) |

Cooling water

|

|

WPC-300 |

300 |

240 |

SJZ65/132 |

37 |

7/7 |

|

WPC-500 |

500 |

350 |

SJZ80/156 |

55 |

8 |

|

WPC-900 |

900 |

350 |

SJZ80/156 |

55 |

9 |

|

WPC-1200 |

1200 |

450 |

SJZ92/188 |

110 |

10 |

Two Step Method Production Line Parameters:

|

Main technical data |

|||||

|

Mode |

Product

(mm) |

Max capacity (kg/h) |

Extruder mode |

Extruder power (kw) |

Cooling water

|

|

WPC-180 |

180 |

150 |

SJ65 |

37 |

7 |

|

WPC-240 |

240 |

180 |

SJ75 |

45 |

7/7 |

|

WPC-300 |

300 |

220 |

SJ80 |

45/75 |

8 |

|

WPC-500 |

500 |

260 |

SJ90 |

75/90 |

9 |

|

WPC-1200 |

1200 |

360 |

SJ120 |

132 |

|

ABEL was established in 2006 ,is specialized in research,manufacture and marketing of plastic extrusion machine ,mixer and mixing plant ,granulating machine .ABEL is located in zhangjiagang city (near shanghai ),jiangsu province,china.

With comprehensive experience, creative and innovative emotion,ABEL develops high-quality products for the market. Highly skilled artisan together with modern processing methods ensure that ABEL has stable and high performance products.

We provide below machines and plants to domestic and international market:

•Extrusion line for profile/pipe

•Mixer and mixing plants for pvc powder

•Screening ,conveying ,packing system for plastic granules

•plastic granulating lines

•Auxiliary machines

•Many leading companies in different industries have cooperated with us ,such as shengqili group(listed company) ,ALBIS PLASTIC GMBW ,TRUPER group mexico,Colormax group ,Green recycle lebanon

Our Mission :Help customers to gain profits and assist customers to sucess. Our development comes from the clients’ satisfaction.

Our aim :to help at least 500 customers to process and produce better products , to effectively use the plastics and to improve people's living environment.

FAQ

Our service&other items

Port of loading

Shanghai, China

Terms of Payment

30% T/T Deposit before production, 70% T/T before delivery.

Delivery Time

The ordered wood plastic composite door frame making machine will be shipped in 30 days after receipt of deposit or after signed contract.

Period of quality warranty

One year

Package

The ordered wood plastic composite door frame making machine will be packed in film or wooden box ,according to customer request.

Observing &Testing

After we receipt 30% advance deposit, we will start to produce. When the machine is completed, buyers come to observe and test machine by themselves, until the machine is satisfied with the buyers, they can pay for the other 70% balance.

Technical documents

The seller should supply buyer the documents for installation and commissioning within 5 days after contract is available, other related documents will be supplied to buyer before shipment.

After-sale service

After sale service shall be done by the seller. Seller will provide all kinds of technical support to the buyer by telephone, fax or email free of charge. After one-year guarantee period, we assure you life-long maintenance.

Installation

We provide electrical control maps and instruction book to you for installation with English instruction. If required, we can send 1 or 2 engineers to buyer’s country for installation and training. But buyer should pay for all expenses, such as: visa, air-tickets, food, accommodation, insurance and also 50 dollars per day for each engineer.