- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yuanhang

-

Voltage:

-

240V

-

Dimension(L*W*H):

-

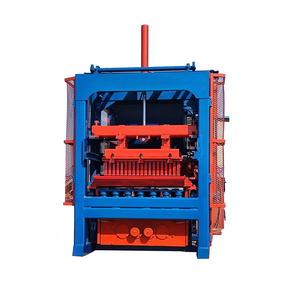

2000*1300*2150

-

Weight (KG):

-

2500 kg

-

Raw material:

-

recycled plastic bricks making machine

-

Block Type:

-

plastic block making machine

-

Product Name:

-

plastic brick making machine

-

Name:

-

plastic brick machine

-

Keywords:

-

plastic brick machine

-

Color:

-

Optional

-

Model:

-

plastic sand tile machine

-

Products:

-

plastic floor tile

-

Brick type:

-

plastic floor tile

-

Machine Type:

-

plastic brick making machine price

Quick Details

-

Type:

-

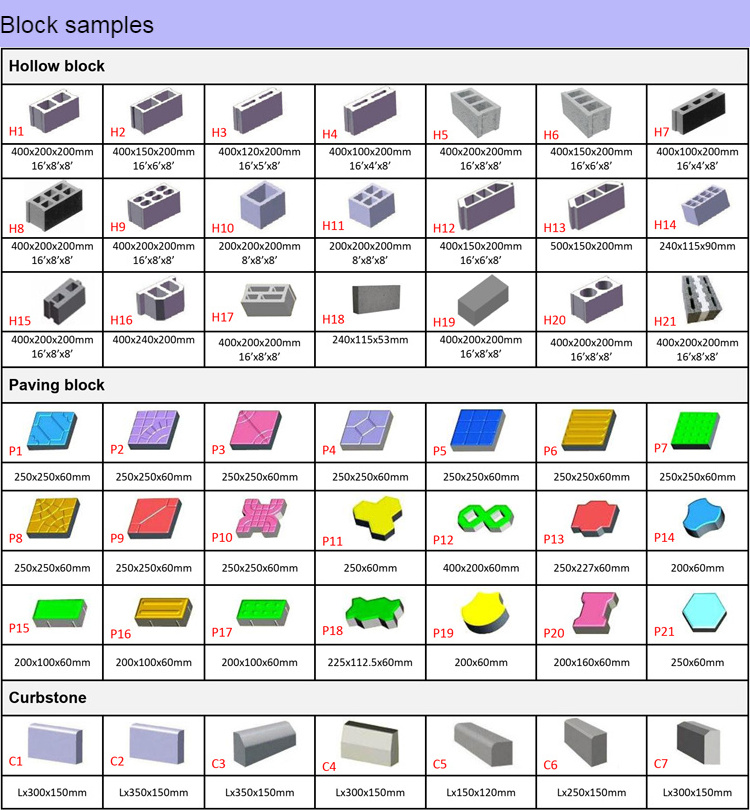

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Autoclaved aerated concrete block (AAC), Other

-

Brick Raw Material:

-

plastic

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours, Other

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yuanhang

-

Voltage:

-

240V

-

Dimension(L*W*H):

-

2000*1300*2150

-

Weight (KG):

-

2500 kg

-

Raw material:

-

recycled plastic bricks making machine

-

Block Type:

-

plastic block making machine

-

Product Name:

-

plastic brick making machine

-

Name:

-

plastic brick machine

-

Keywords:

-

plastic brick machine

-

Color:

-

Optional

-

Model:

-

plastic sand tile machine

-

Products:

-

plastic floor tile

-

Brick type:

-

plastic floor tile

-

Machine Type:

-

plastic brick making machine price

|

Automatic plastic brick wall panels plastic moulds for concrete building block machine recycled plastic bricks making machine

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

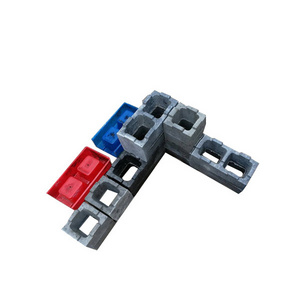

plastic brick making machine

:

The main raw materials of plastic brick machines are plastic bottle, plastic barrels, plastic plates and other waste plastic for recycling and regeneration, energy saving and environmental protection.

The main raw materials of plastic brick machines are plastic bottle, plastic barrels, plastic plates and other waste plastic for recycling and regeneration, energy saving and environmental protection.

plastic brick making machine

, high degree of automation and fast speed. You can make

hollow brick

machines,

solid

brick machines, and paving brick machines.

1.

Before shipping,

we provide you with machine packaging video

to satisfy you.

2.

Provide delivery video,

The transportation logistics trajectory

of the cargo,

online inquiry

. Safe and rest assured.

3. Provide

operation manual and installation manual

for free.

4.

S

enior engineer online technical guidance

. Solve difficulties for you.

5.

S

enior engineers come to work locally

. Turnkey projects. Let you have no trouble.

6.

5 years of warranty

to ensure that the machine can run smoothly in the future.

Our Advantages

plastic brick machine,

plastic brick making machine,

recycled plastic bricks making machine,

plastic brick making machine recycled,

plastic bricks molding,

plastic block making machine,

recycling machine for plastic waste to make bricks,

plastic interlocking brick,

plastic floor tile,

plastic sand tile machine

Q1: What is the warranty for this machine?

A1: 3 years excluding the easy wear parts.Spare parts is recommended to keep at least one year in case of emergency

Q2: What kind of material is this machine made of ?

A2: Stainless steel and carbon steel.

Q3: When can I get the price?

A3: Within 24 hours. If urgent, please directly call us.

Q4: Can the price be much lower?

A4: Our MOQ is the very reasonable price for 1 set, but with big order, we can apply to our Manager to provide a proper discount.

Q5: Do you offer oversea installation?

A5: We'll send professional installation engineer to help you install the equipment, as well as train your workers freely.

Yuanhang Group Machinery Equipment Co.,Ltd is the high-tech enterprise, integrating R&D, manufacture and trade as one body forclay brick making production line machinery and hoffman kiln and tunnel kiln construction .

Our equipment is superior handling , advanced technology and reliable quality . We provide raw material analysis, site planning,kiln construction , equipment installation and trial running services. We have a professional technicians and engineers teams tosupport your project . After years of hard exploration, we have established a set of complete and effective service system forbefore sales , medium sales and after sales .

Our products exported 28 countries and regions , like Indonesia, Myanmar, Kazakhstan, Uzbekistan, Russia, Nepal, Sudan, SouthAfrica, Uganda , Peru , Chile , etc . Our products enjoy a great reputation during the customers and have been sold all over theworld .

Welcome you to visit us ! Let’s walk hand in hand , and win the world together !

Our equipment is superior handling , advanced technology and reliable quality . We provide raw material analysis, site planning,kiln construction , equipment installation and trial running services. We have a professional technicians and engineers teams tosupport your project . After years of hard exploration, we have established a set of complete and effective service system forbefore sales , medium sales and after sales .

Our products exported 28 countries and regions , like Indonesia, Myanmar, Kazakhstan, Uzbekistan, Russia, Nepal, Sudan, SouthAfrica, Uganda , Peru , Chile , etc . Our products enjoy a great reputation during the customers and have been sold all over theworld .

Welcome you to visit us ! Let’s walk hand in hand , and win the world together !

Our Service

Pre-Sales Service

* Device model choice.

* Design and manufacture products according to the special requirements of customers.

* Train technicians for customers.

* Send engineers and technicians to the customers to plan the site and design the best process and plan free of charge.

After-Sales Service

* Create a customer profile and track it

* Detailed registration and storage of the daily information and processing of the hotline.

* Notify the equipment customers who have passed the warranty period and regularly inform the equipment maintenance details

* Conduct statistical analysis on product quality and service issues to improve quality services.

Hot Searches